Table of Contents

Epoxy

TLDR notes:

- Fiber: bulk material for standard packages can be removed using a fiber laser (ex: PDIP or COB)

- However the laser will damage the die surface if you try to go all the way to the surface

- CO2 laser will work for COB but not standard packages (ex: PDIP)

- Lower peak power ⇒ melts silica instead of ablating it

- “Blue light” systems are slow (hours) but can work on all package types

- Commercial version: FALIT EcoBlue

- Here's some similar research: https://github.com/LawrenceBrode/LACED

- We've also had moderate success locally heating acid with laser, but its not developed enough to have specific recommendations

- What sort of laser did you use? How did you stop it from obliterating the die?

- Just a cheap laser off AliExpress. 3.5 watt 445nm output. Powerful enough to burn epoxy away (and the bond wires) but not powerful enough to burn silicon.

General results

- Some settings work decent

- Possibly COB epoxy is easier to laser than package epoxy

- Risk of melting bond wires and/or die

- Use lower power and/or pulsed?

- Practice on samples before trying something you care about

- Puts off nasty fumes. Make sure to have good ventilation

From Sam Wagner:

- “We use a yterrbium fiberlaser. What you are doing is trying to cause the plastic compound to explosively eject the silicon beads. So a pulsed laser is critical. The laser melts the plastic and the pulse hopefully causes it to vaporize and eject beads.”

- “Important to note that if you see silicon, you’ve destroyed the chip and can now no longer do FA work. We stop at the bond wires and use acid or plasma to remove the rest. Then it’s off to SEM or TIVA/LIVA or whatever you’re next step is.”

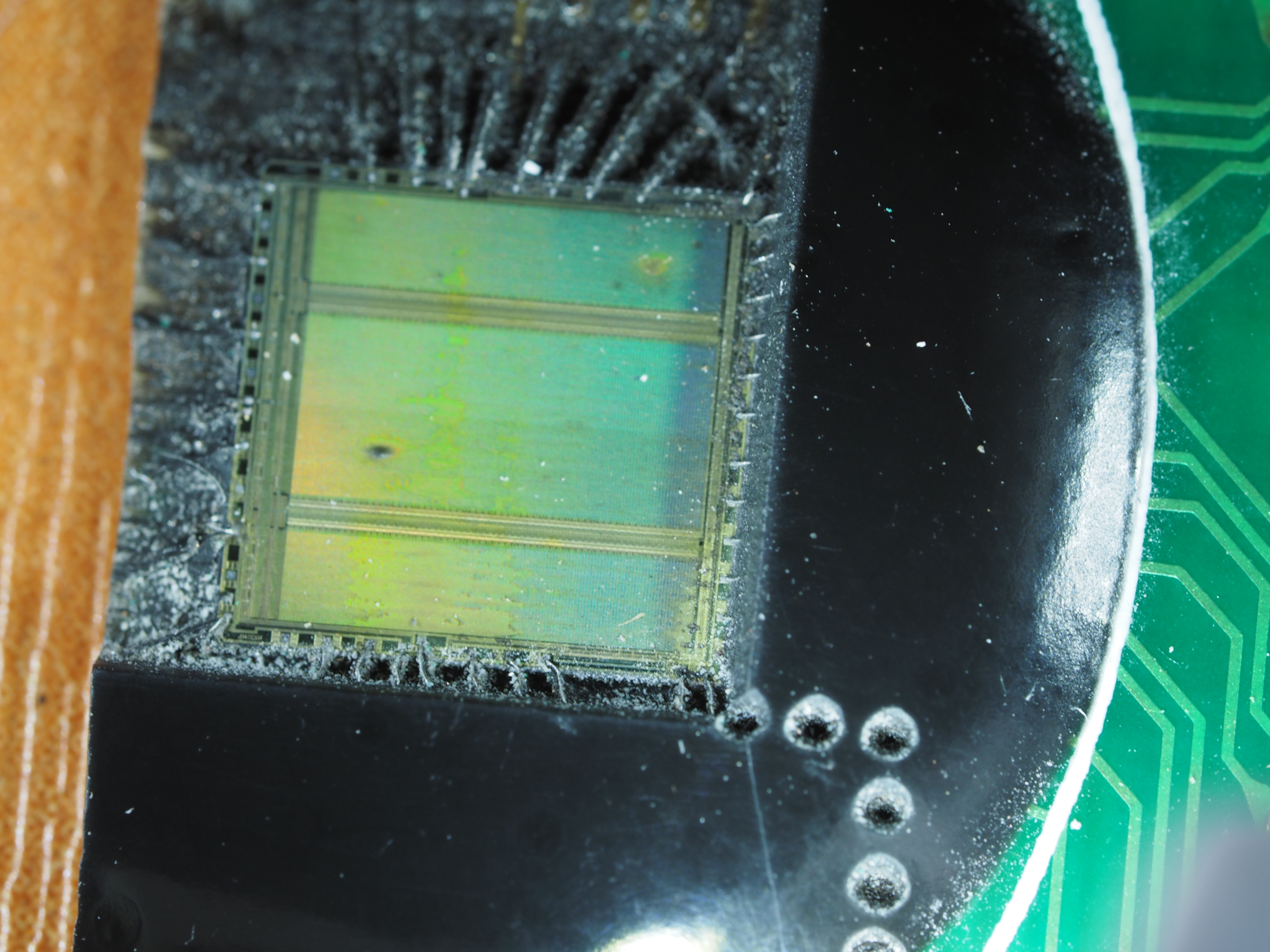

jamiecraig

Above: laser decap from below (Source)

https://www.jamiecraig.com/de-encapsulating-ics-with-a-laser-cutter/

- Seemed to work okay

- What would it look like if touched up with WFNA?

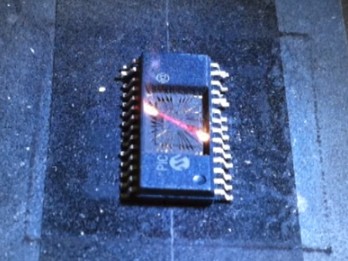

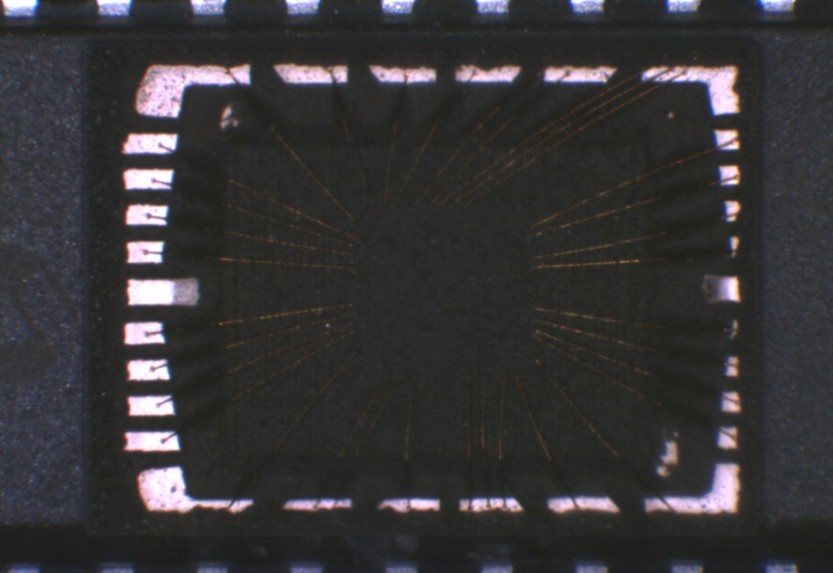

EMSL 6502 test

Silicon Exposed

Above: source

http://siliconexposed.blogspot.com/2013/08/laser-ic-decapsulation-experiments.html

- Poor results

- Cranberry glass

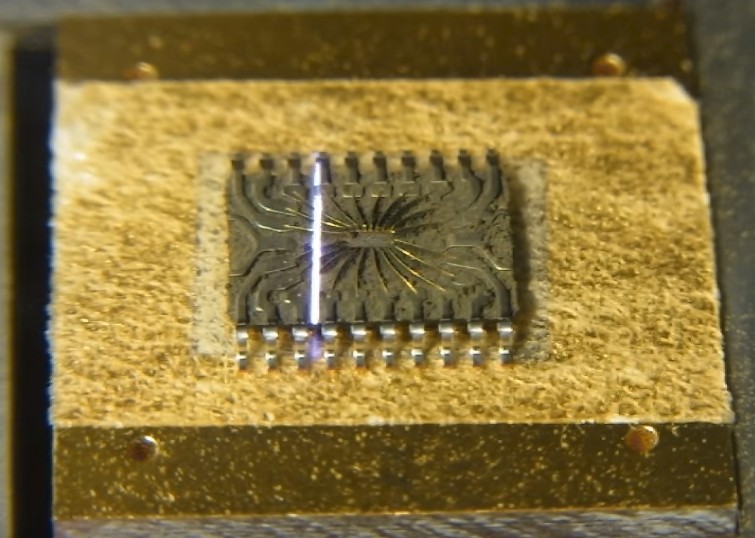

Laser Decap Pro

https://www.youtube.com/watch?v=-x4lyX1C4q0

- Gold backing block

- Good leadframe exposure

- Die unclear how well exposed

- Scanned entire chip (including die area) up until the end

- Raster scan is horizontal, vertical, and diagonal

Sesame 1000

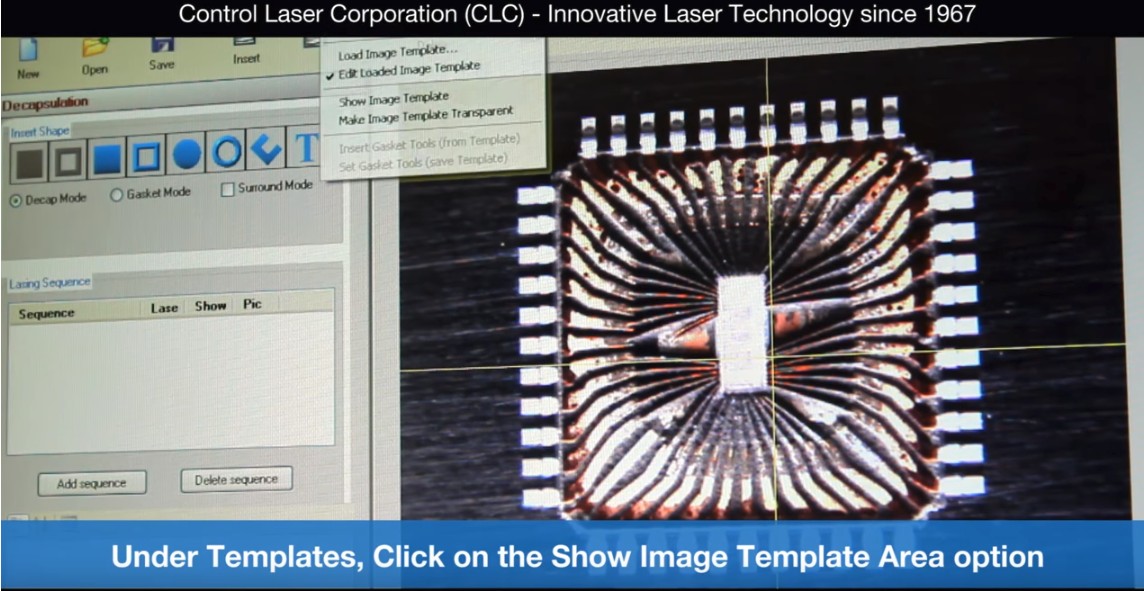

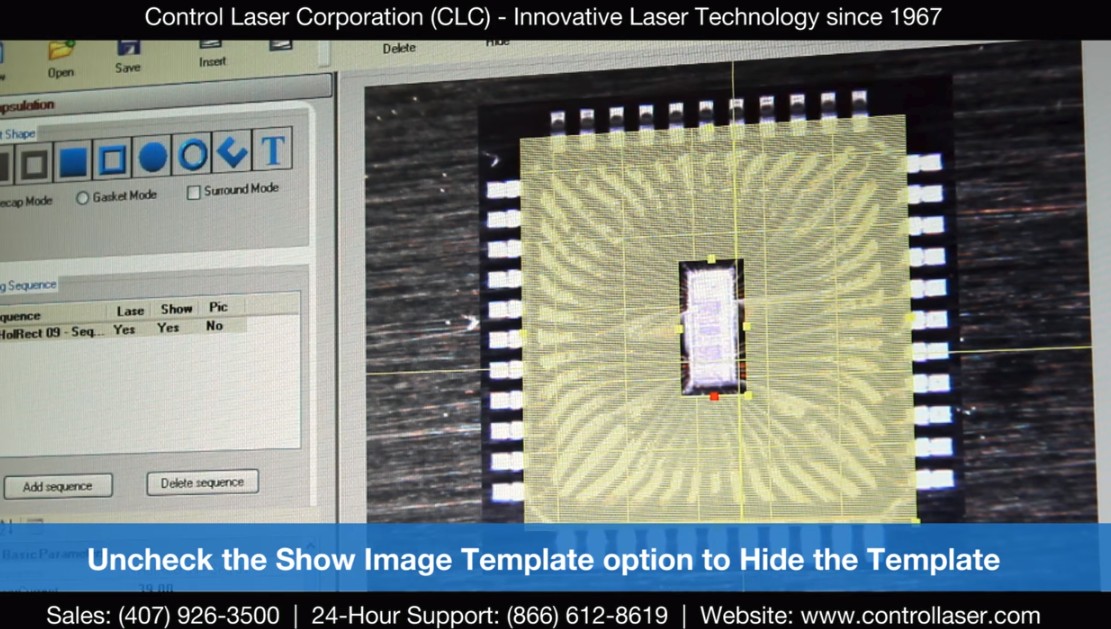

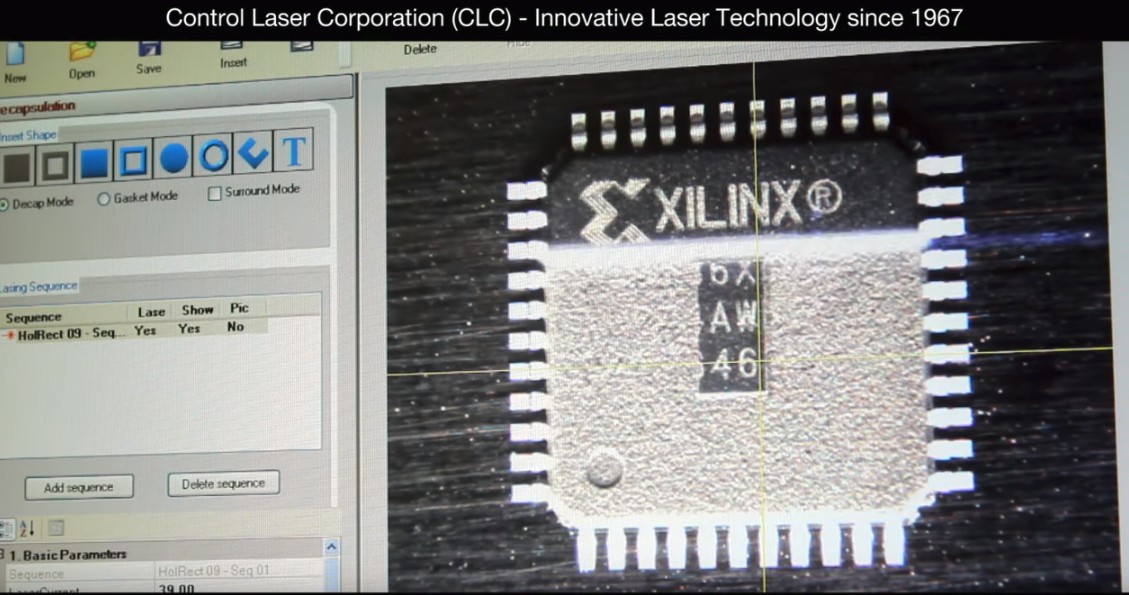

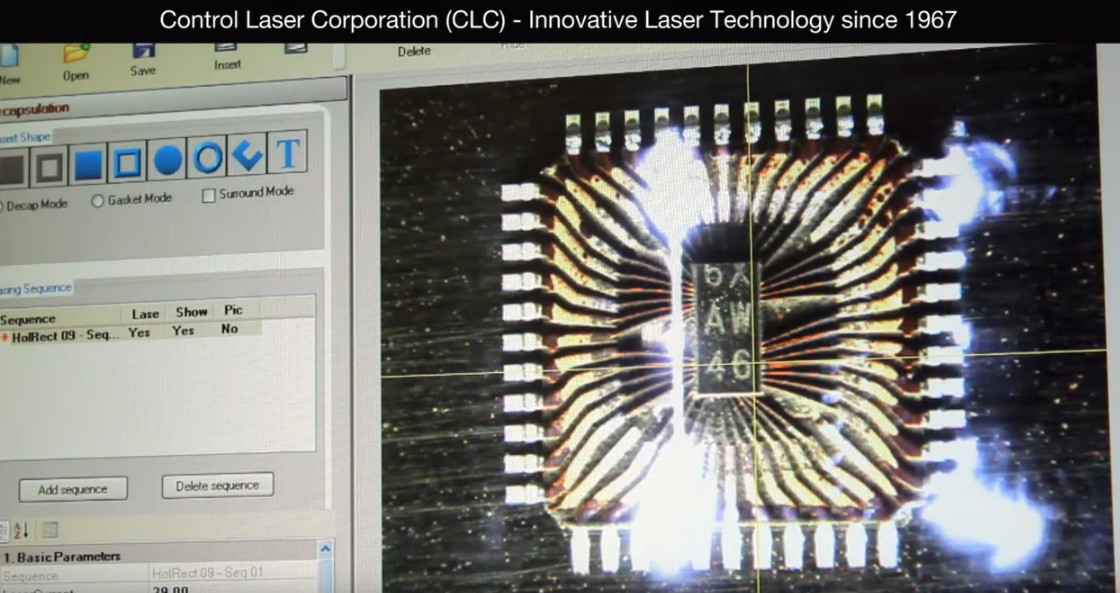

CLC ControlLaser FALIT

https://www.youtube.com/watch?v=SvWgSs2_f00

- Laser Decapsulation FALIT System Software | Image Templates

- Pro system demo

- Has nice features like overlaying x-ray, CSAM, or other guiding image

- Laser scan was horizontal, vertical mix

Light Ray

https://www.youtube.com/watch?v=sSRl3Vqbos8

- They do the whole chip but avoid die area

- Light Ray - IC Decapsulation

mcmaster ezlaze

TODO: add pictures, estimate material removal rate

Basically this was too slow to be practical except for very small samples. That said, it did work very well. A quicklase or other higher throughput Nd:YAG system would likely work well

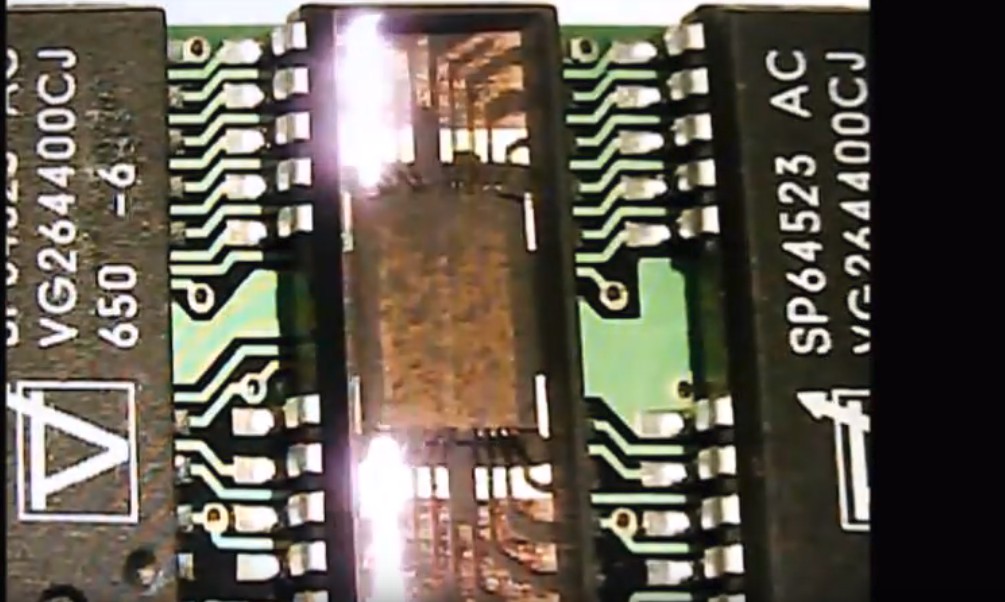

mcmaster PLCC

Remove bulk epoxy

https://twitter.com/johndmcmaster/status/1641575200109244416

Metal

Can be used to cut open package

Ceramic

Seems to also work

McMaster UV tests

2025-05-25

Tried to get Genmitsu unit to see if it would by chance work. 1) too long of wavenlength (probably. 455 nm vs want more 400 nm) 2) came defective

2025-07-25

going to try this

https://www.amazon.com/F-Yi-Engraving-Machine-Printer-Industrial/dp/B07CRV1STJ/