This is an old revision of the document!

Lid

The metal page has some general tips.

Cutting

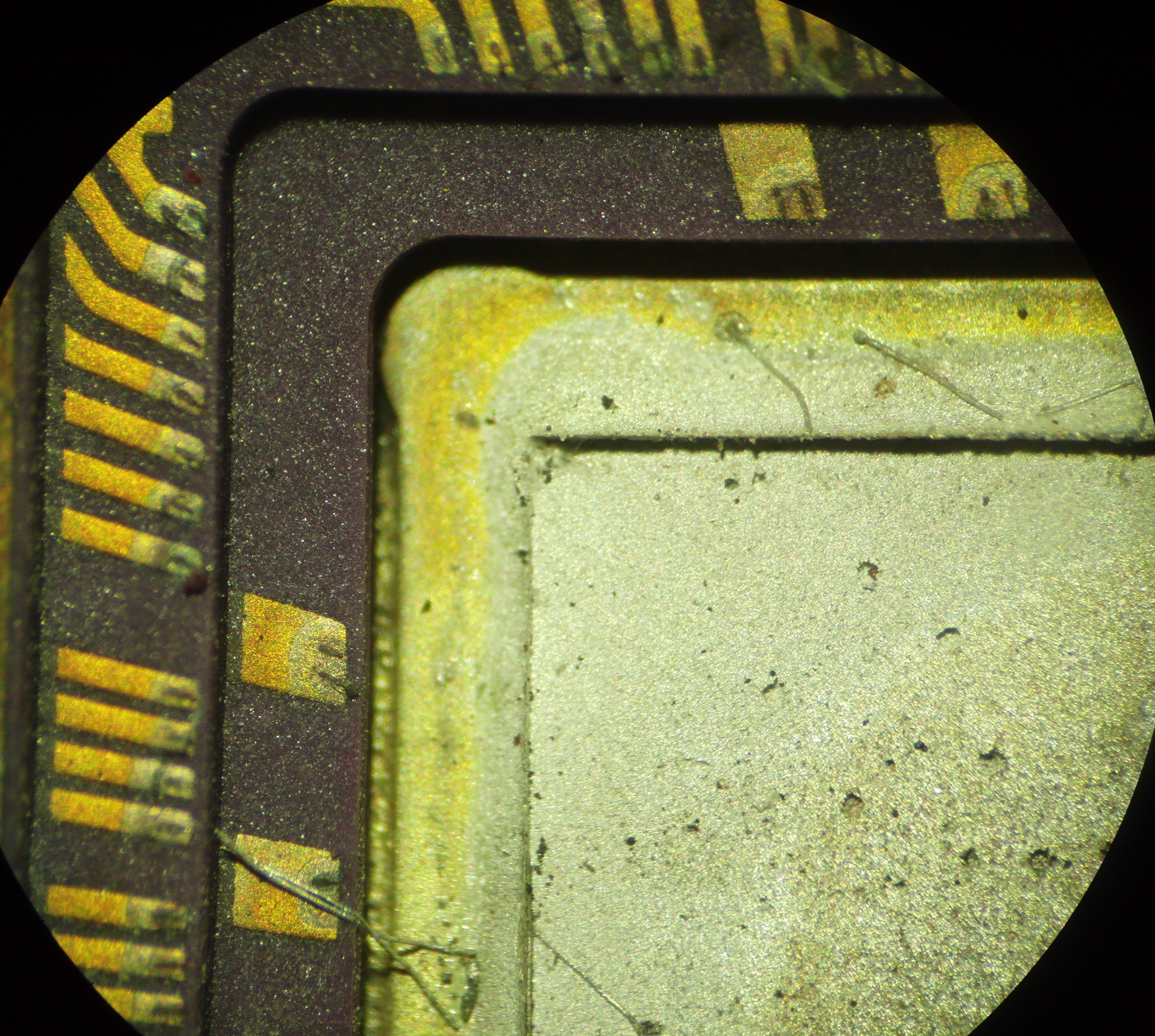

A little less safe than metal cans because the cutting wheel will be very close to the bond wires. Additionally, some lids bend easily under pressure and so may press on the bond wires before they start cutting. The chip won't give way around the ceramic but it still ma get pressed down around the edges.

Thermal

Ceramic-metal lids can also be removed with a torch. However, it is easy to warp the ceramic package making it difficult to get a good image of the die.

Laser

[Ultratec] video shows a package being opened…not sure what type, but I'm assume metal as ceramic would be very hard to vaporize.

Die

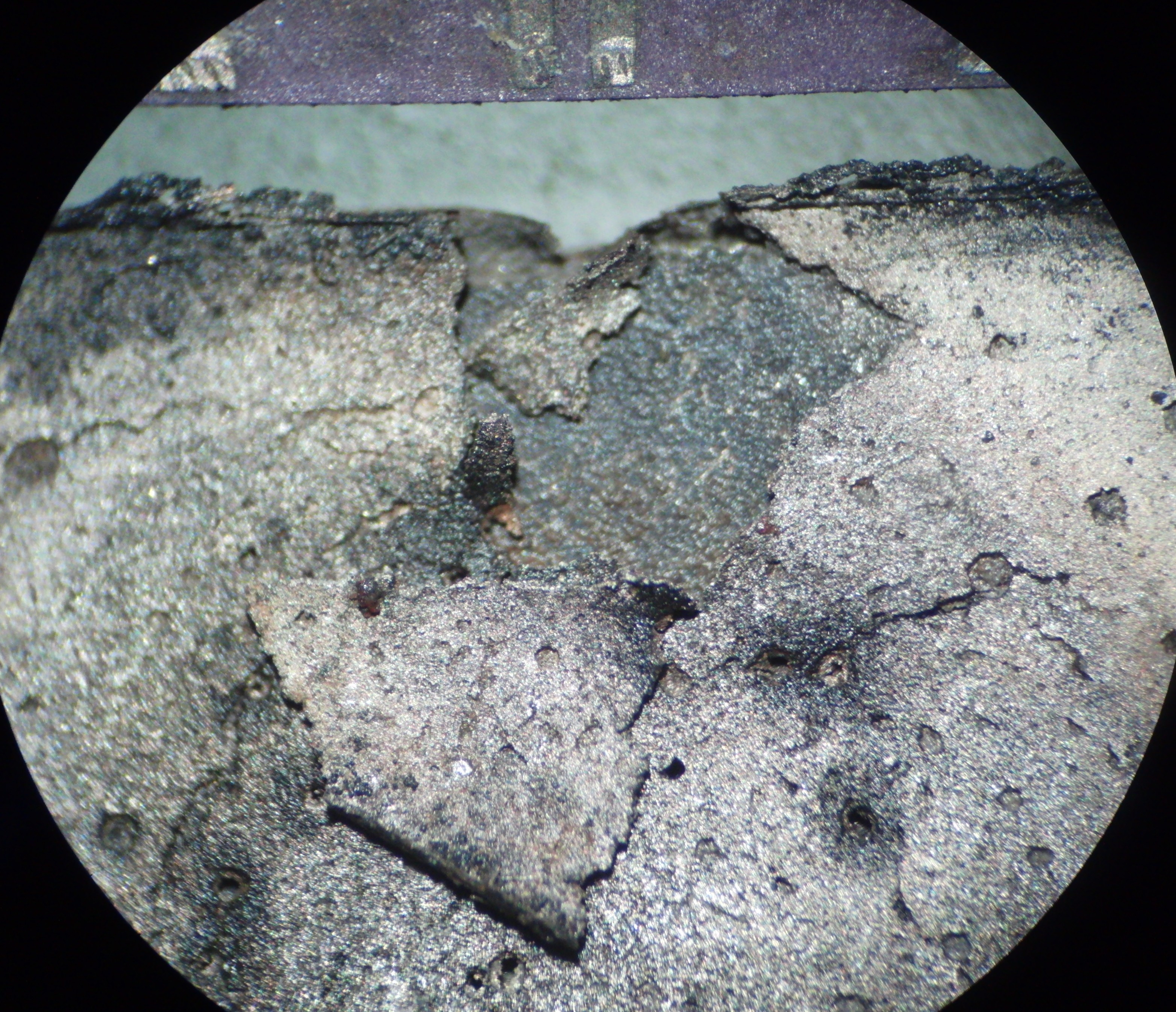

Sometimes dies are soldered to a substrate (eg: silver heatsink / carrier). Example after die was removed (by force):

Note the raised corners. This means that without completely melting the solder it is hard to get loose. Soak in nitric acid and it should quickly dissolve and come loose:

Of course, it might take a while to get under the entire die. Heating without will help to get it off but I have found that it can take a lot of force to move even with solder melted and so its best to chemically remove as much silver as possible first.

References

- Ultratec's “Decapsulation of ceramic packages”: http://www.youtube.com/watch?v=IzlFw0Cz-Cw&feature=related