Table of Contents

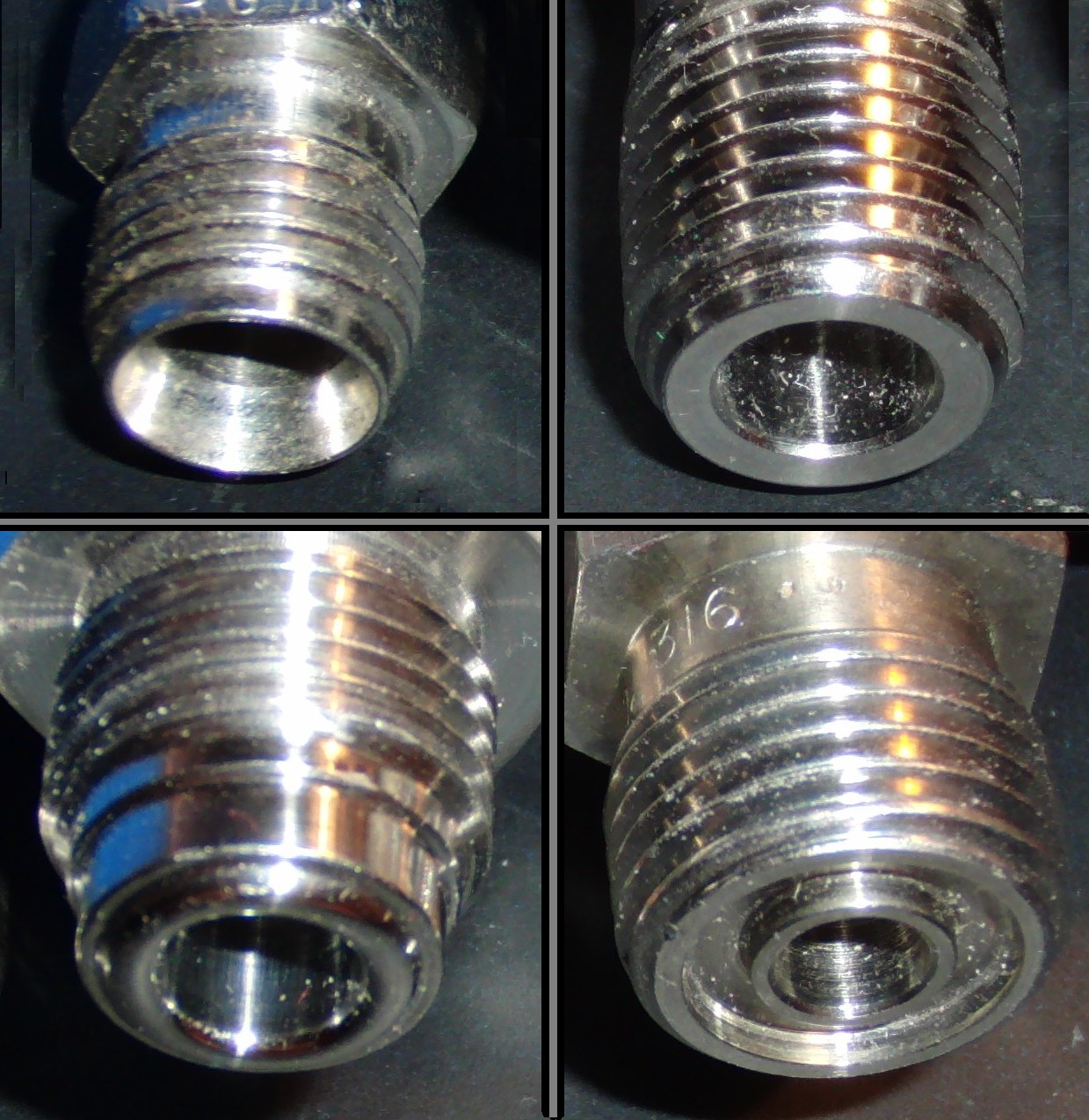

Various male fittings used in vacuum applications. Upper left: Swagelok tube fitting, upper right: NPT, lower left: VCR, lower right, VCO

Connector comparison

Swagelok tubing postfix codes [Vacuum Tubing Products]

| End Connection(s) | Designator |

|---|---|

| VCR female one end only | FR |

| VCR female both ends | DFR |

| VCR female one end, VCR male other end | FMR |

| VCR female one end, XBA adapter other end | FRB |

| VCR male one end only | MR |

| VCR male both ends | DMR |

| VCR male one end, XBA adapter other end | MRB |

| VCO female one end only | FO |

| VCO female both ends | DFO |

| VCO female one end, VCO male other end | FMO |

| VCO female one end, XBA adapter other end | FOB |

| VCO male one end only | MO |

| VCO male both ends | DMO |

| XBA adapter one end only | -B1 |

| XBA adapter both ends | -B2 |

Installation

Tube fittings require simple hand tools as do VCR fittings. VCO are probably just as easy if not easier than VCR

Seal

My guess is that VCR fittings seal best. Tube fittings probably seal pretty good the first time used but may lose their seal if not carefully re-installed.

VCO likely doesn't seal as well as VCR but probably worse than a properly installed tube fitting as well.

Reusability

VCR gaskets should be used fresh for each install but you can probalby get away with reusing the same gasket a few times for most applications. Swagelok tube fittings can be re-installed to the same location as long as they are installed in the same orientation. However, to get a proper tube fitting seal on a new surface with used fittings I imagine you'd have to replace the ferrule which is probably more expensive and labor intensive than replacing a simple VCR gasket.

VCO gaskets/fittings can be reused many times. Gaskets are inexpensive to replace if damaged.

Pressure

Didn't see ratings specific to particular connector types. However, [Vacuum Tubing Products]:

- “1/4 in. outside diameter tube—ultrahigh vacuum (10 –9 torr) to 100 psig (6.8 bar)

- 3/8 in. through 1 1/2 in. outside diameter tube—ultrahigh vacuum (10 –9 torr) to 25 psig (1.7 bar)”

Temperature

[Vacuum Tubing Products]:

- “VCR end connections—70 to 1000°F (20 to 537°C)

- VCO end connections—70 to 400°F (20 to 204°C), based on standard fluorocarbon FKM O-ring material

- XBA end connections—70 to 1000°F (20 to 537°C)

- When used with Ultra-Torr fittings—70 to 400°F (20 to 204°C)”

Custom builds

Tube fittings are relatively easy to cut and crimp on new fittings.

Unfortuntaley, because VCR glands are special ends larger than the tube itself, they must be TIG welded in place as needed. TIG welding requires equipment and a reasonable amount of skill. I'm guessing that pro shops use orbital welders

Swagelok tube fitting

Above: male Swagelok tube fitting

Very common in many applications, usually with 1/4“ OD tube size.

Components of a connection:

- Fitting body (female side)

- Nut

- Front ferrule (large cone)

- Back ferrule (washer like piece)

Installing

Steps [STFI]:

- Ensure that tubing is bur free

- Insert ferrule into mating service

- Attach nut but don't tighten it (just needs to guide tube at this point)

- Insert tubing into nut against ferrule

- Tighten using wrench

- 1/4”: 1-1/4 turns

- 1/16“, 1/8”, 3/16“: 3/4 turn

- Support other side using another wrench or vice

Tip: mark nut with a pen before turning to make it more obvious where in the turn you are

Use Swagelok gap inspection gauge to inspect distance: it should not fit if the fitting is sufficiently tight [STFI]

Re-installing

When disassembling, strip the connection so that original position can be determined

Steps [STFI]:

- Insert tube + ferrule assembly into mating service

- Slide down nut and finger tight to original position

- Tighten it “slightly”

Do not use gap inspection gauge [STFI]

Sourcing

Include:

- Swagelok

- Tubelok

- Friend says these don't go through same QA process that Swagelok does and so hes not allowed to use them at work. It may simply due to traceability for critical applications and unclear what actual quality difference is

VCR

Above: male VCR fitting (no gasket installed)

Uses a knife edge on consumable metal gaskets to achieve seal. Most of the part numbers user 1/16's of an inch to indicate size.

Components of a connection [Installing VCR]:

- Body (the male side)

- Gasket

- Gland (the female side)

- Silver plated female nut

Body has drilled out holes for leak testing.

Since these are knife edges they must be protected against damage. Above: cap to protect edges when not connected

Gasket types

Above: used retainer gasket

Look like washers. Ex:

- Stainless steel silver plated 0.25” non-retaining: SS-4-VCR-2

- Stainless steel silver plated 0.25“ side load retainer: SS-4-VCR-2-ZC-VS

- Stainless steel silver plated 0.25” retaining: SS-4-VCR-2-GR

- What is difference to SS-4-VCR-2-GR-VS?

Types [Installing VCR]:

- Retainer gasket conveniently snaps in place

- Nearly 3 times as expensive as non-retain gasket

- Side load retainer gasket

- Can be installed in tight spaces

- Non-retain gasket

Materials [Installing VCR]:

- Stainless (ex: SS-8-VCR-2, blue bag, 0.5“)

- Tighten: 1/8 turn

- Nickel (ex: NI-8-VCR-2, black bag, 0.5”)

- Tighten: 1/8 turn

- Copper

- Tighten: 1/4 turn

- Aluminum

- Tighten: 1/4 turn

Installing

Retainer gasket [Installing VCR]:

- Snap gasket onto male gland

- Tighten female nut finger tight

- Use pair of wrenches to tighten

Side load gasket [Installing VCR]:

- Slide gasket onto male gland

- Tool available to pick up

- Tighten female nut finger tight

- Use pair of wrenches to tighten

Non-retain gasket [Installing VCR]:

- Place gasket into female nut

- Tool available to pick up

- Tighten female nut finger tight. Should engage to last thread if installed properly

- Use pair of wrenches to tighten

Flexible tubing

Part numbers:

- 321-4-X-12DFR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 12 in. Nominal Produced Flexible Length, Female VCR Both Ends”

- 321-4-X-12DMR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 12 in. Nominal Produced Flexible Length, Male VCR Both Ends”

- 321-4-X-12FMR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 12 in. Nominal Produced Flexible Length, Female VCR x Male VCR”

- 321-4-X-24DFR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 24 in. Nominal Produced Flexible Length, Female VCR Both Ends”

- 321-4-X-24DMR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 24 in. Nominal Produced Flexible Length, Male VCR Both Ends”

- 321-4-X-24FMR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 24 in. Nominal Produced Flexible Length, Female VCR x Male VCR”

- 321-4-X-36DFR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 36 in. Nominal Produced Flexible Length, Male VCR Both Ends”

- 321-4-X-4FMR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 4 in. Nominal Produced Flexible Length, Female VCR x Male VCR”

- 321-4-X-6DFR: “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 6 in. Nominal Produced Flexible Length, Female VCR Both Ends”

- 321-4-X-6FMR “321 Stainless Steel Flexible Tubing, 1/4 in. OD, 6 in. Nominal Produced Flexible Length, Female VCR x Male VCR”

Because of the gland nature it would seem hard to convert the more readily availble Swagelok tube adapters to VCR fittings without using a separate tube fitting to VCR adapter

Naming seems to follow MAT-OD-X-LENPFX

- MAT: 321 for 321 stainless steel

- OD: outer diamter of tubing as 16ths of an inch (4/16 = 1/4)

- X: flexible convoluted tubing?

- LEN: length in inches (which part exactly?)

- PFX: postfix

Naming examples:

- 321-4-X-2FR: 321 SS, 1/4“ OD tubing, with VCR female on one end

- 321-4-X-2DFR for convoluted tubing with VCR female on both ends

VCO

Above: male VCO fitting (no gasket installed)

VCO is similar to VCR except that instead of using consumable metal gaskets it uses o-rings.

References

- Swagelok tube fittings installation (STFI): https://www.youtube.com/watch?v=FdthSQDH8qk

- Installing a VCR Metal Gasket Face Seal Fitting (Installing VCR): https://www.youtube.com/watch?v=5z_ZRt51sqo

- Swagelok flexible tubing: http://www.fiting.sk/catalog/pdf_en/0131.pdf