This is an old revision of the document!

Table of Contents

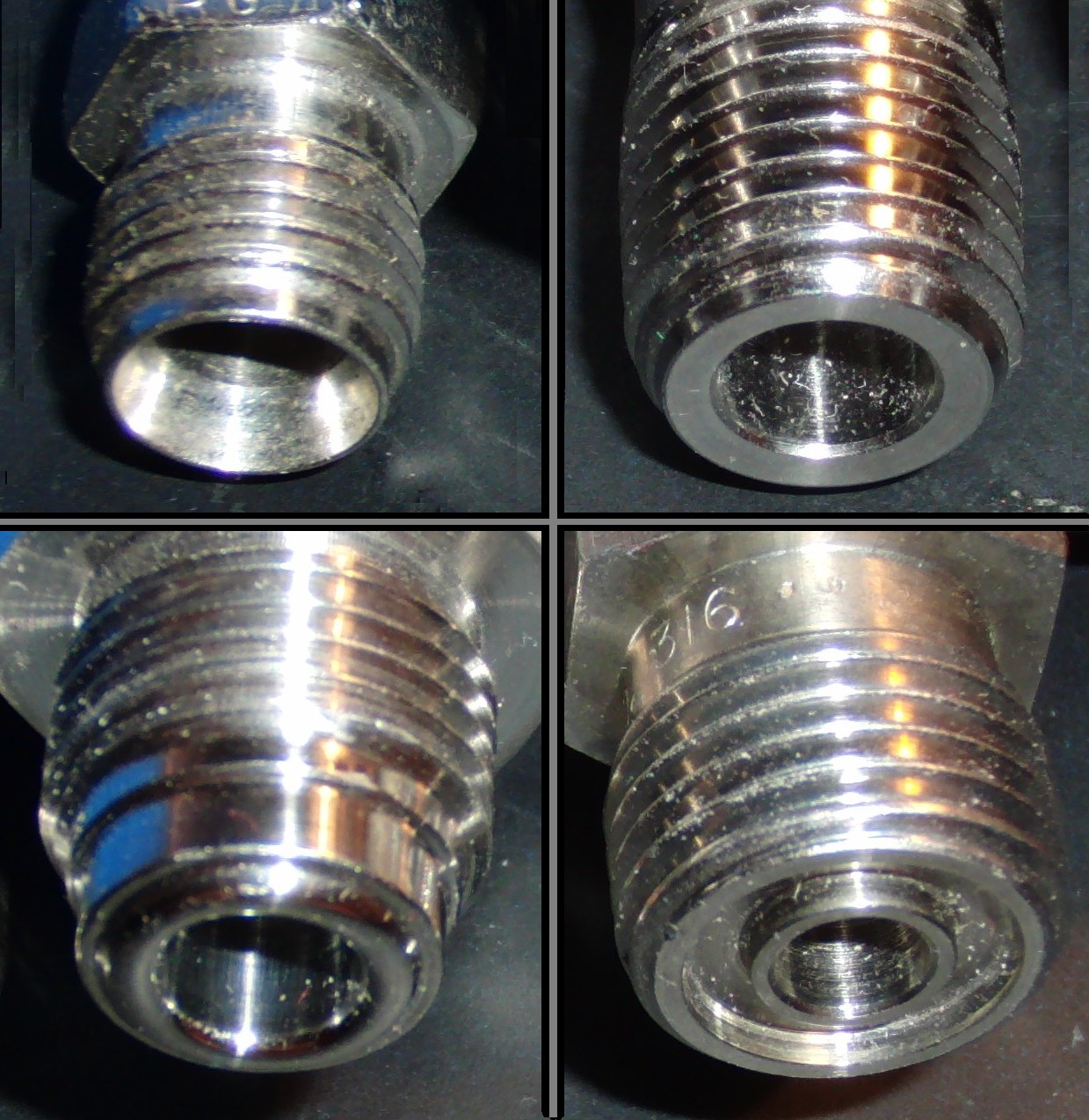

Various male fittings used in vacuum applications. Upper left: Swagelok tube fitting, upper right: NPT, lower left: VCR, lower right, VCO

Swagelok tube fitting

Above: male Swagelok tube fitting

Very common in many applications, usually with 1/4“ OD tube size.

Components of a connection:

- Fitting body (female side)

- Nut

- Front ferrule (large cone)

- Back ferrule (washer like piece)

Installing

Steps [STFI]:

- Ensure that tubing is bur free

- Insert ferrule into mating service

- Attach nut but don't tighten it (just needs to guide tube at this point)

- Insert tubing into nut against ferrule

- Tighten using wrench

- 1/4”: 1-1/4 turns

- 1/16“, 1/8”, 3/16“: 3/4 turn

- Support other side using another wrench or vice

Tip: mark nut with a pen before turning to make it more obvious where in the turn you are

Use Swagelok gap inspection gauge to inspect distance: it should not fit if the fitting is sufficiently tight [STFI]

Re-installing

When disassembling, strip the connection so that original position can be determined

Steps [STFI]:

- Insert tube + ferrule assembly into mating service

- Slide down nut and finger tight to original position

- Tighten it “slightly”

Do not use gap inspection gauge [STFI]

Sourcing

Include:

- Swagelok

- Tubelok

- Friend says these don't go through same QA process that Swagelok does and so hes not allowed to use them at work. It may simply due to traceability for critical applications and unclear what actual quality difference is

VCR

Above: male VCR fitting (no gasket installed)

Uses a knife edge on consumable metal gaskets to achieve seal. Most of the part numbers user 1/16's of an inch to indicate size.

Components of a connection [Installing VCR]:

- Body (the male side)

- Gasket

- Gland (the female side)

- Silver plated female nut

Body has drilled out holes for leak testing.

Since these are knife edges they must be protected against damage. Above: cap to protect edges when not connected

Gasket types

Above: used retainer gasket

Look like washers. Ex:

- Stainless steel silver plated 0.25” non-retaining: SS-4-VCR-2

- Stainless steel silver plated 0.25“ side load retainer: SS-4-VCR-2-ZC-VS

- Stainless steel silver plated 0.25” retaining:VCR-2-GR-VS

Types [Installing VCR]:

- Retainer gasket

- Side load retainer gasket

- Can be installed in tight spaces

- Non-retain gasket

Materials [Installing VCR]:

- Stainless (ex: SS-8-VCR-2, blue bag, 0.5“)

- Tighten: 1/8 turn

- Nickel (ex: NI-8-VCR-2, black bag, 0.5”)

- Tighten: 1/8 turn

- Copper

- Tighten: 1/4 turn

- Aluminum

- Tighten: 1/4 turn

Installing

Retainer gasket [Installing VCR]:

- Snap gasket onto male gland

- Tighten female nut finger tight

- Use pair of wrenches to tighten

Side load gasket [Installing VCR]:

- Slide gasket onto male gland

- Tool available to pick up

- Tighten female nut finger tight

- Use pair of wrenches to tighten

Non-retain gasket [Installing VCR]:

- Place gasket into female nut

- Tool available to pick up

- Tighten female nut finger tight. Should engage to last thread if installed properly

- Use pair of wrenches to tighten

VCO

Above: male VCO fitting (no gasket installed)

VCO is similar to VCR except that instead of using consumable metal gaskets it uses o-rings.

References

- Swagelok tube fittings installation (STFI): https://www.youtube.com/watch?v=FdthSQDH8qk

- Installing a VCR Metal Gasket Face Seal Fitting (Installing VCR): https://www.youtube.com/watch?v=5z_ZRt51sqo