This is an old revision of the document!

Lid

Professional labs use miniature can openers to avoid getting any fragments into the package since failure analysis may want to see if the device failed from particulates. For RE purposes a Dremel can suffice followed by a good clean.

http://www.youtube.com/watch?v=lt_zFq4qzd0

Ceramic-metal lids can also be removed with a torch. However, it is easy to warp the ceramic package making it difficult to get a good image of the die.

Die

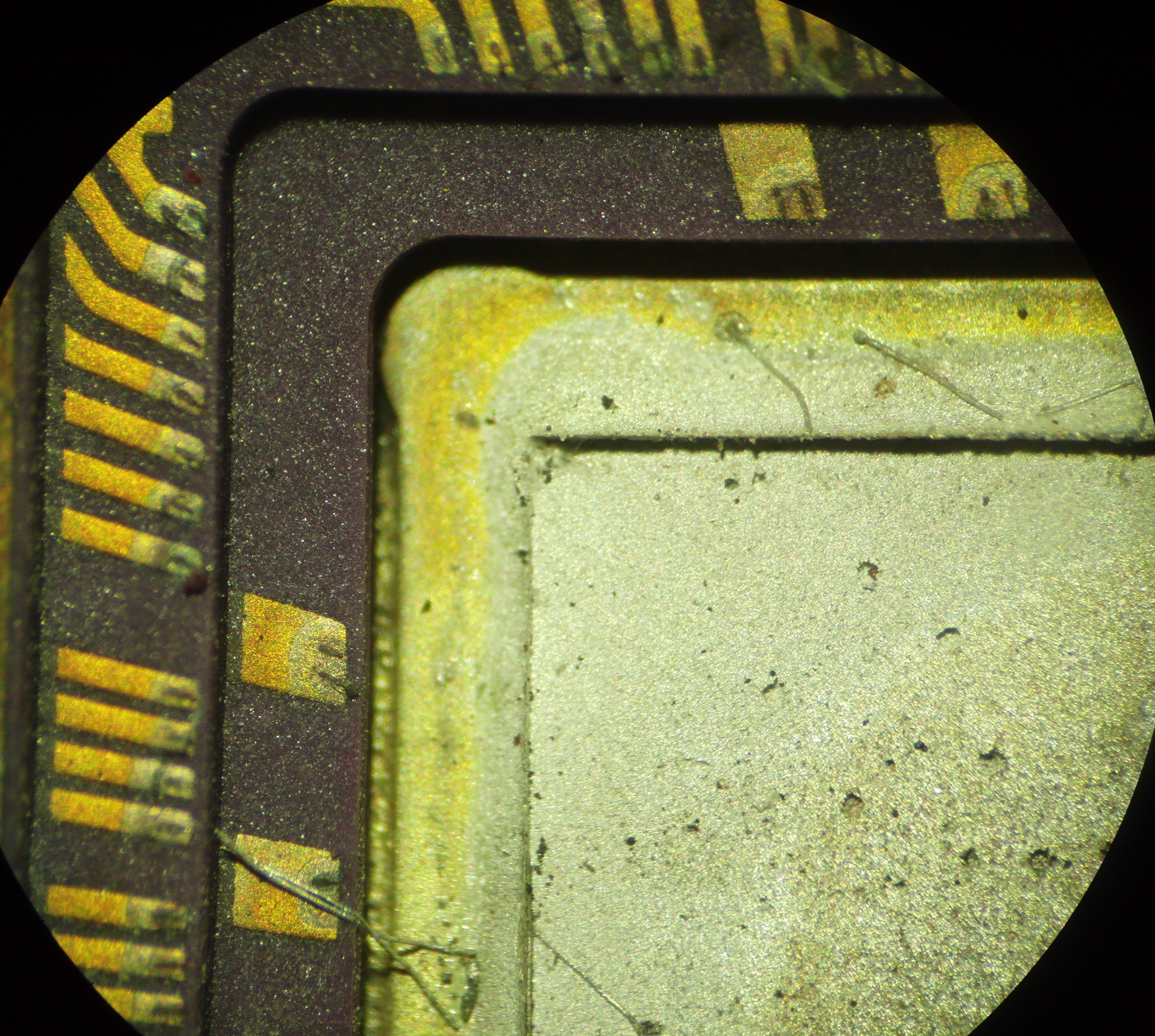

Sometimes dies are soldered to a substrate (eg: silver heatsink / carrier). Example after die was removed (by force):

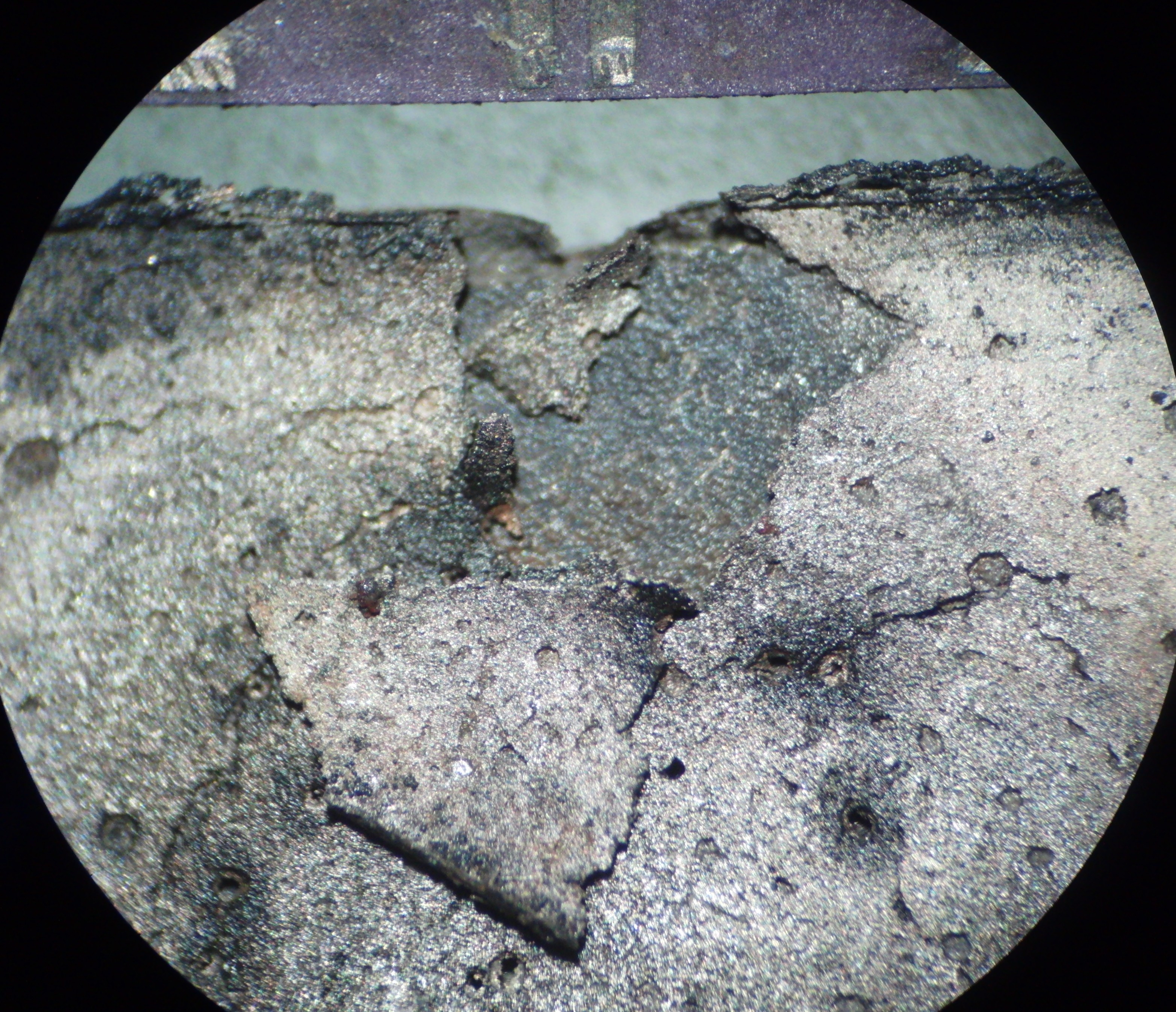

Note the raised corners. This means that without completely melting the solder it is hard to get loose. Soak in nitric acid and it should quickly dissolve and come loose:

Of course, it might take a while to get under the entire die. Heating without will help to get it off but I have found that it can take a lot of force to move even with solder melted and so its best to chemically remove as much silver as possible first.