Table of Contents

This page is for automation, particularly for microscope stages. Most precision stages employ some sort of micrometer, 40 TPI is common. However, you can still get reasonable precision at lower threadings. For example, the Sherline 2000 CNC stage that I used originally is only 20 TPI (precision 1/4-20 leadscrew) but was plenty good for most operations. Although the actual precision doesn't have to be as good, you may run into higher backlash and other issues that could make CNC planning and image stitching harder.

Motorized micrometer

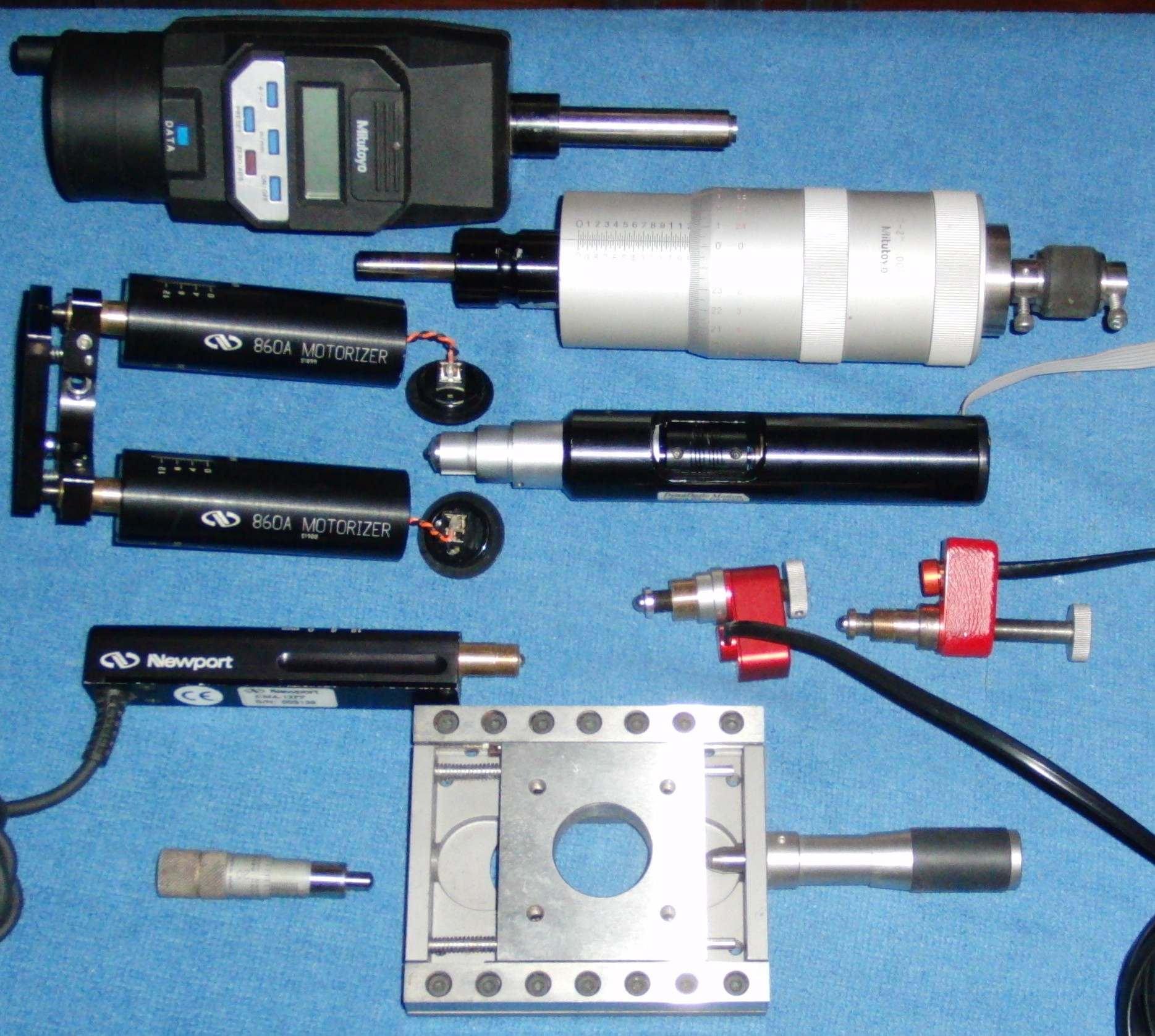

Above: assortment of manual, motorized, and DRO micrometers

These are easy to deploy and work with many existing stages. That is, they can be cost effective in that they can be picked up and then used to retrofit an existing piece of equipment like the mirror mount above.

New Focus Picomotor

Uses piezoelectric static/dynamic friction motors. The New Focus 8095 would probably be my choice for fine positioning, roll, pitch, and z in particular. These stages are low profile, very stable, and very precise. Some disadvantages are that they have relatively short lives compared to conventional motors and that they might be more expensive due to more limited availability compared to more conventional motors. As of 2012 at auction they go for about $100 for a used 1“ travel unit. Controllers appear much less often but go from $50-200 for both “network” (computer controlled) and regular varieties.

Yaw might be usable depending on how much correction is needed. I imagine X/Y would be too slow and high precision for scanning.

Newport

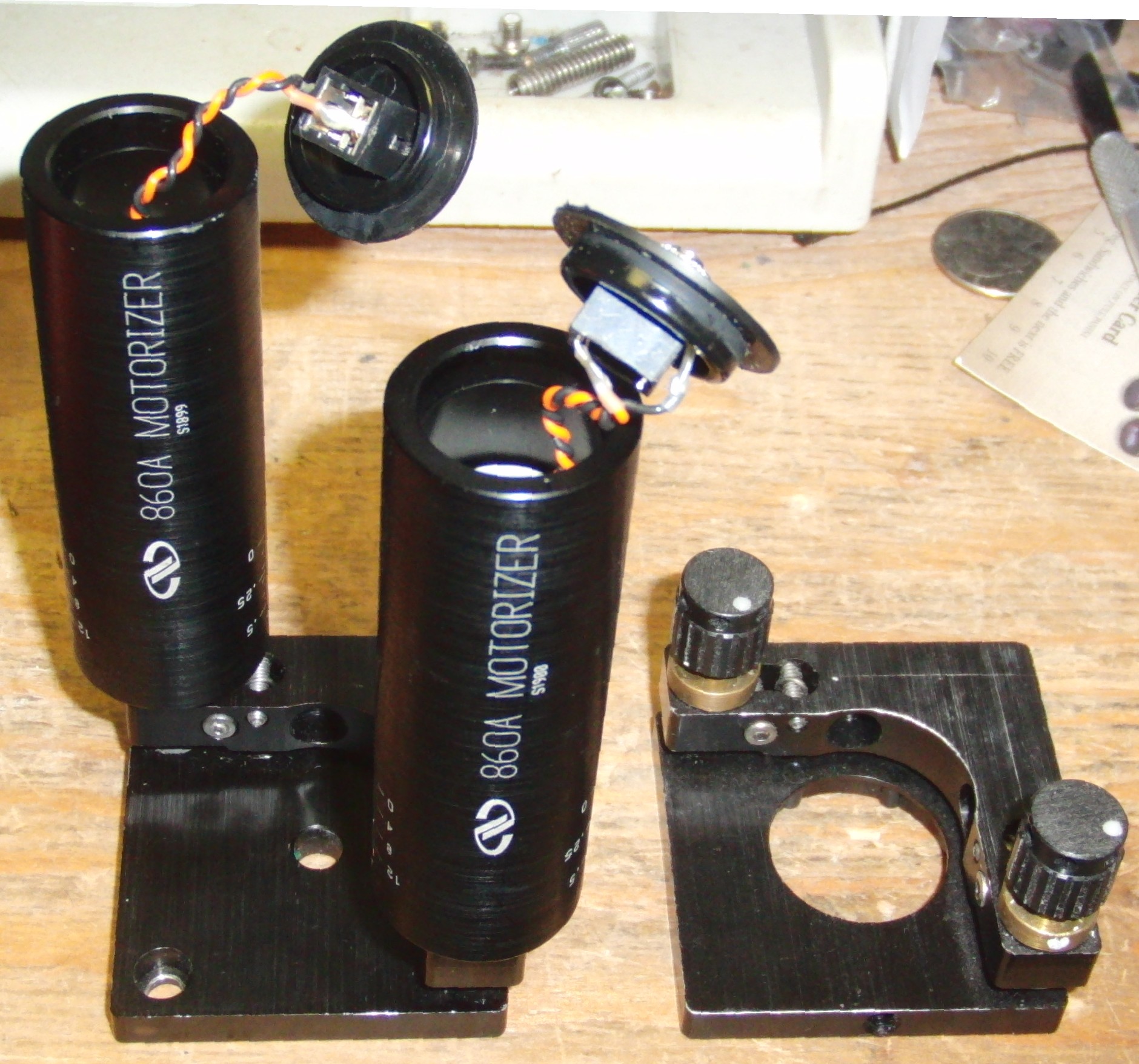

860A

Somewhat large DC actuator. I got a few for $35 each. They got rejected for use on the CNC microscope because they are too big and get in the way of hte objectives.

DynaOptic

Makes some actuators that look to be a little smaller than the Newport 860A. Maybe stepper motors? Haven't arrived yet. I got a few for $40 each, a foreign seller was asking $100 each for the same units.

Oriel makes some similar ones. Is DynaOptic the OEM?

Motorized stage

These tend to be more common. The more modular / easier to use assemblies use NEMA steppers or similar. However, these tend to be too large and most stages aim to be low profile. Therefore, DC servo and variable reluctance motors are more common.

Klinger

The most widely available on the surplus market are probably Klinger (purchased by Newport). They typically use variable reluctance motors with an expensive connector so make sure that you can drive them. I created a makeshift connector adapter and tried to drive them like steppers but found that I couldn't get enough torque to drive them under load. I eventually hacked on some NEMA 17 steppers with the caveat that they no longer had full clearance and no longer had optical encoding.

Newport

The “normal” Newport stages are very nice but also tend to be the most expensive.