Table of Contents

The composition of purple ceramic IC packages has not been publicly documented as far as we are aware (if anyone has a link to a reliable source, feel free to add it!) so we decided to figure things out for ourselves.

Analysis performed by azonenberg on 10/16/2012 at approximately 17:00 EDT.

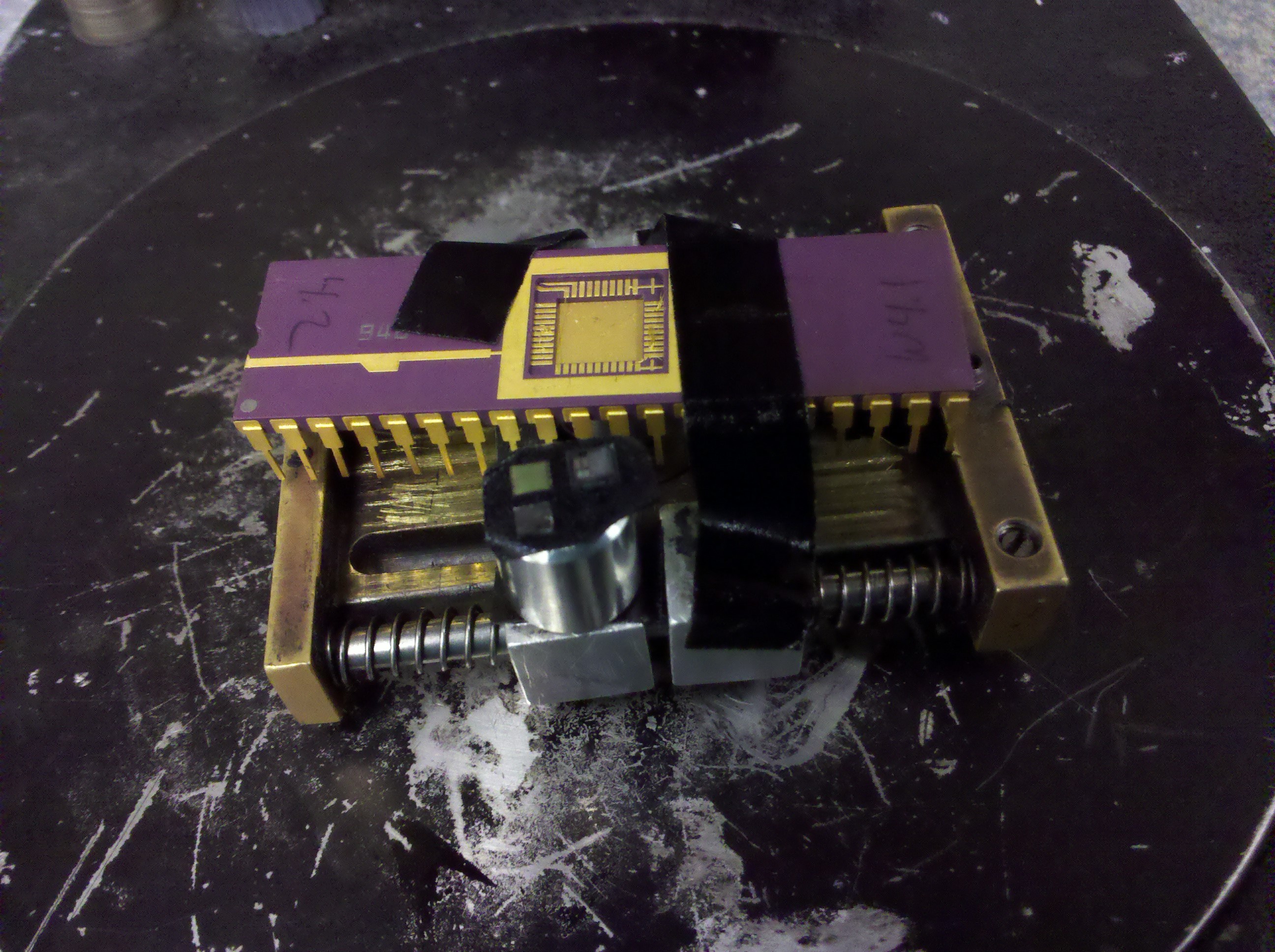

Sample overview and preparation

The sample was a 40-pin CDIP with gold plating that had been used by someone at the RPI cleanroom to practice wire bonding on. The die attach area and leadframe were covered with poorly adhered bonds.

The sample was placed on top of a standard pin stub mount with double-sided carbon tape and then tape was run along both rows of pins, over the top of the chip, and to the sample holder. It was hoped that this would avoid charging without the need to coat the sample.

The sample was inserted into the chamber of the SEM (JEOL JSM-840 using tungsten filament) and almost immediately began to charge severely. Since the evaporator was down for repairs at the time, carbon coating was impossible so the sample was removed from the chamber and sputtered with the standard thickness of Pt (several angstroms). It was considered unlikely that the coating would be of sufficient thickness to interfere with analysis. Once coated, no charging was observed.

All analysis was conducted at 20kV accelerating voltage and 12mm working distance.

SEM imaging

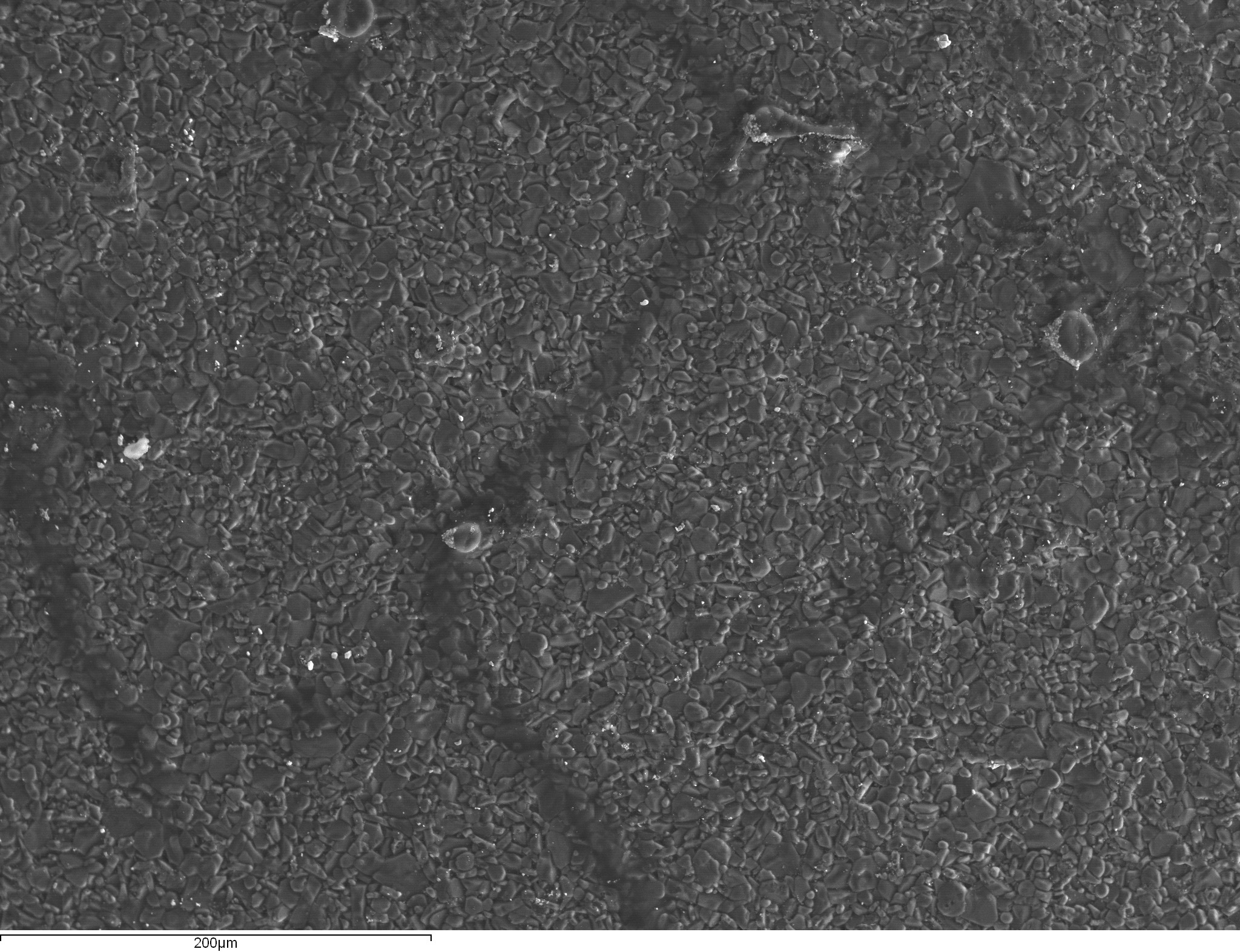

Low-magnification secondary electron image showing general sample morphology

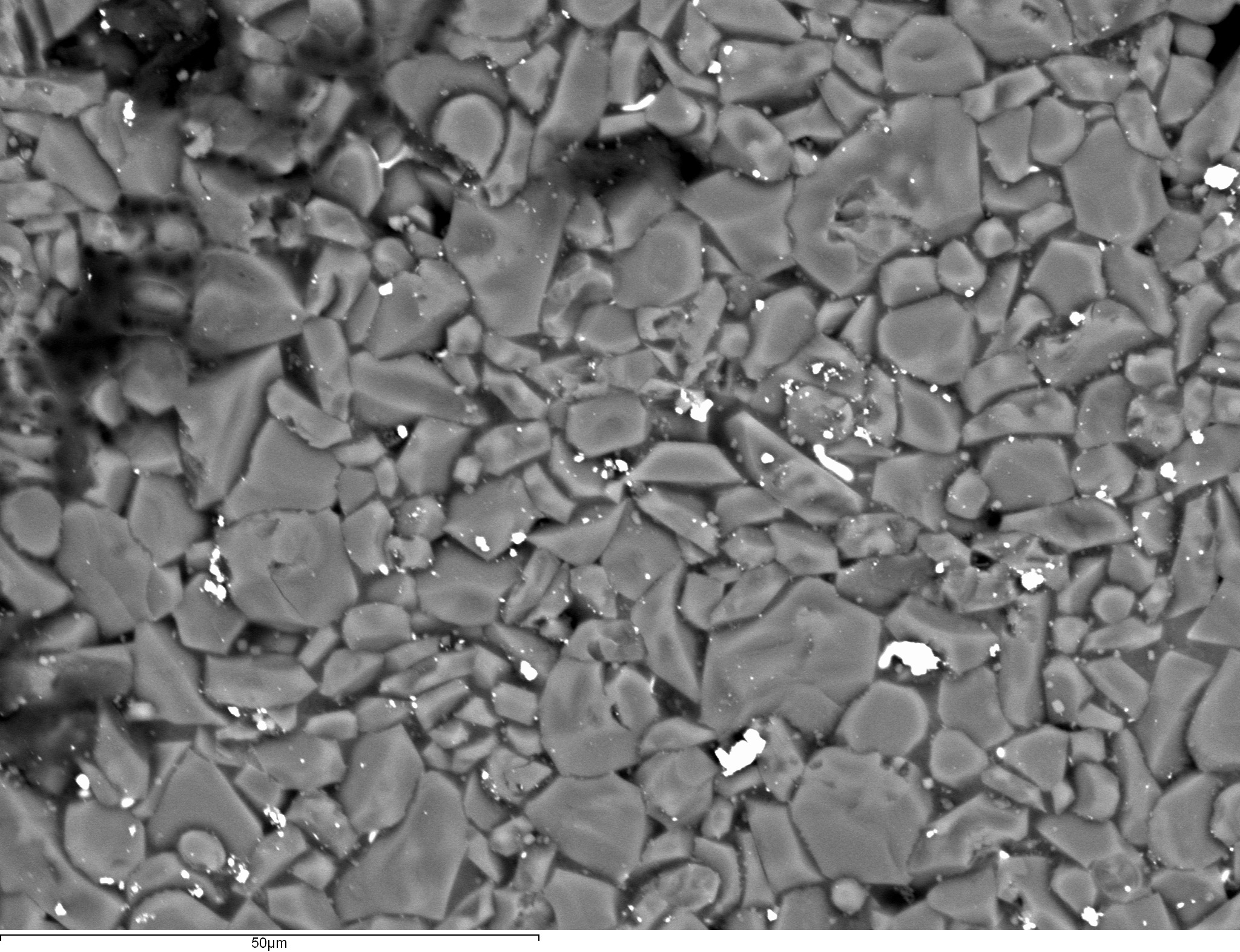

Higher magnification backscatter image (composition mode). General lack of Z-contrast suggest granules are mostly homogeneous and of uniform composition. Some in the upper left and sides are darker. These are likely to be regions with lower Cr content. Given the topography of the sample it was difficult to determine how much of the contrast was due to Z variation.

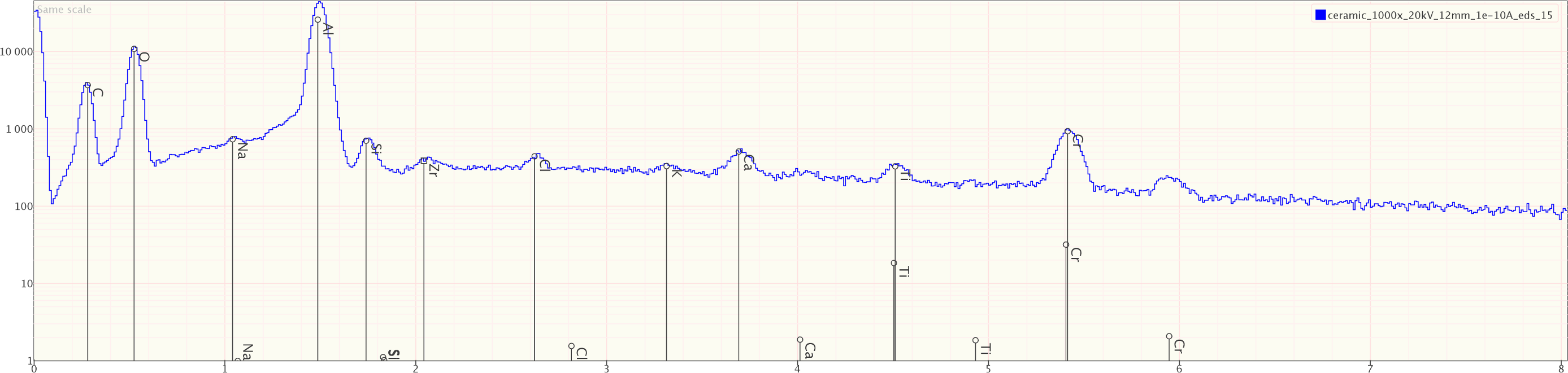

EDS

An EDS spectrum was taken from the bulk ceramic. The detector was an Oxford Instruments Si(Li) detector using a Moxtek polymer/aluminum window with 77% open area.

Acquisition time was 741.6 seconds real time, 499 seconds live time. Approximately 48,000 counts were registered on the Al Kα peak.

Spectral lines observed and most likely origins:

- C Kα (FEBID from hydrocarbon vapor contaminants in chamber, skin particles from the chip being handled)

- O Kα (the material is an oxide-based ceramic)

- Na Kα (NaCl deposits from sweat).

- Al Kα (Al2O3, the bulk of the ceramic).

- Si Kα (SiO2)

- Cl Kα, Kβ (NaCl, KCl, CaCl deposits from sweat)

- K Kα (KCl deposits from sweat)

- Ca Kα (CaCl deposits from sweat, may also be some CaO in the ceramic). Overlaps with Cr Kα - Si Kα escape peak so hard to be certain.

- Ti Kα (TixOx. Maybe Ti2O3 as this has a similar structure to Al2O3 and has a violet-black color.)

- Cr Kα, Kβ (CrxOx. Cr2O3 is used in a commercial purple ceramic containing chromium and aluminum oxides so this is the most likely form.) Cr Kα - Si Kα escape peak overlaps with Ca Kα but the peak looks too big to be purely an artifact so there is likely Ca present as well.

- Zr Lα? (ZrO2. Very weak but this is my best guess of what it could be.)

Annotated spectrum:

Conclusions

The sample is composed primarily of alumina and silica, with titanium, chromium, and zirconium oxides present in small volume. (No standard-based quantitative calibration was performed so it is impossible to give exact proportions.) While the oxidation states cannot be determined from EDS, preliminary reading of chemical properties suggests that Ti2O3, Cr2O3, and ZrO2 are the most probable compounds.

Reading of the MSDS for the commercial ceramic linked above, SiO2 and TiO2 are typical impurities in such ceramics. Na2O, CaO, and MgO are also mentioned as possible impurities. No Mg was observed and Na/Ca are present in sweat so the data is inconclusive as to whether they are present in the ceramic itself.

Based on the above MSDS it is considered unlikely that the Cr in purple-ceramic IC packages is present in the hexavalent form (CrO3) however this is a reddish-purple color so the possibility remains. The bulk ceramic should be relatively harmless in either case however dust-generating operations such as sanding should be avoided and hands washed after contact with it.