Table of Contents

This page is about various forms of dry etching involving exciting a gas to modify an IC. Reactive Ion Etching (RIE) is used most so page focuses on that.

Plasma machining, aka plasma etching, seems to be professional general decapsulation method of choice. Reactive Ion Etching (RIE) uses RF and etchant gases to chemically decompose a sample. Unlike many chemical methods, RIE is anisotrophic making it suitable for etching high resolution lithography. As an analyst tool it provides a good way to both delayer and even decapsulate chips, although it tends to be much slower than alternative methods.

A typical RIE setup (an “asher”) has a bottle of gas such as SF6 fed into a quartz tube with a sample in it. The quartz tube is surrounded by magnetic coils emitting typically 13.56 MHz radio waves.

As the process is very slow, you should X-ray of the chip and then mill down to as close as possible to the die. Finish the remaining epoxy off with a plasma etcher.

Advantages

- Very precise

- Repeatable

- Can involve less toxic alternatives to HF chemical etching

- HF intermediate is short lived and in small quantity

Disadvantages

- Slow (hours…maybe near a day?)

- Moderately high startup cost (likely at least few k USD)

- Some processes (particularly for metals) involve toxic reactants/byproducts

Although there are many design variations, at the highest level there are two types:

- Barrel etcher: creates a uniform, non-directed plasma

- Parallel plate etcher: creates a directed plasma

Process flows are often measured in Standard Cubic Centimeters per Minute (SCCM). That is, the amount of gas that would be dispersed at 1 atm at 25C in 1 cubic centimeter. This is important because this is a fixed amount of mass and you can control how many molecules / second are being injected regardless of the pressure. You also can use scale constants to convert from one gas to another.

[Beck 102] reccomends using a surface profiler (ex: Dektak 3030) to measure layer thickness

Also see SEM coating which has some relevant info on choice of inert gas, general frequency effects, and other stuff

Secondary plasma [Optimization of IEP]: “Plasma can also be provided as an indirect process where the excitation takes place outside of the sample process chamber. This is referred to as secondary plasma. In this case, a primary chamber is attached to a secondary chamber. The gas is ionized in the primary chamber. The reactive species are then made to migrate toward the secondary chamber where the samples are processed”

RIE is a comromise of trading chemical etching for mechanical wear on a sample. Some of the very important parameters to consider when chosing a process:

- Aspect ratio: how much width are you losing for each bit of height you take off?

- Selectivity: what else does it etch beside the material you are trying to remove?

- Volatility: did you chemically transform the etched areas into something that will come off?

- TODO; think about how can use this to advantage to make areas unreactive. Could we for example add some sort of iron gas to react with Si to favor SiO2 etching?

[Plasma Etching Outline, 20] notes the following:

- Physical (sputtering): directional but poor selectivity. Low pressure (<50 mTorr)

- Reactive ion etching: variable anisotropy, variable selectivity. 100 mTorr

- Chemical plasma etching: isotrophic, fast, highly selective. 400 mTorr

[Plasma Etching Outline] notes the following parameters can be varied:

- Reactor

- Material of Chamber Walls

- Material of Electrodes

- Geometry (grounded versus powered electrode area)

- Platform Temperature

- Geometry of Gas Flow

- Pumping Speed

- Power

- Frequency

- Gas Supply

- Composition

- Flow rate

- Pressure

- Residence Time

Discharge types

[Plasma Etching Outline]: “Most thin film processes utilize glow discharges, but “plasmas” and “glow discharges” are often used interchangeably”

Plasma discharge

[Plasma Etching Outline]: “partially ionized gas containing an equal number of positive and negative charges, as well as some other number of none ionized gas particles”

Glow discharge

[Plasma Etching Outline]: “globally neutral, but contains regions of net positive and negative charge”

DC bias

Choice of frequency

Popular frequencies:

- DC

- 40 kHz

- 13.56 MHz

- 2.45 GHz

[Optimization of IEP] says both DC and 2.45 GHz are popular for plasma surface treatment.

[Optimization of IEP]: “…three separate regions found in the secondary plasma field. The first is the decaying plasma region. Here, the ion species immediately decrease due to diffusion and recombination. The second region is the Near Afterglow region where the primary active species are the longer- lived free radicals. The last region, Far Afterglow, has virtually no active species.”

“Although there are a number of differences in the practical operation of AC plasmas, the principles of DC glow discharges can be applied to AC. One simply considers the AC as a rapidly reversing DC plasma.” [Plasma Etching Outline]

DC

This section is relavent to AC plasma as well since AC plasmas also create DC biases

Terms:

- Anode: +V applied to it

- Attracts electrons

- Cathode: -V applied to it

- Attracts ions

[Optimization of IEP]: “The design choice of DC plasma excitation offers the benefit of an inexpensive power source to generate plasma.”

[Optimization of IEP]: “DC voltages do not effectively couple well inside plasma, and therefore, require the use of extremely high voltages for initial excitation.”

[Optimization of IEP]: “A common design choice for a DC system is the utilization a Tantalum filament (or similar material such as Tungsten) to ignite very intense argon plasma in the primary chamber. Magnetic force is then used to draw the ions into the main process chamber cavity where secondary hydrogen plasma is ionized. The magnetic force is used in the system as a means to improve the uniformity of species distribution”

[Optimization of IEP]: “oxygen is not recommended, as it quickly burns out the costly Tantalum filament”

[Optimization of IEP]: “The lack of ion species in the plasma chamber may be beneficial in aggressive wafer fabrication processes”

General AC

Bias often added to achieve various effects. 13.56 MHz is popular for generally being a good compromise on multiple fronts.

“AC voltage overcomes the problem of charge which accumulates on a dielectric in the DC system. The positive charge which accumulates due to ion bombardment during one half of the AC cycle can be neutralized by electron bombardment during the next half cycle” [Plasma Etching Outline] Believe I read that you can take advantage of this by placing a capacitor to bias one side and not the other

“The frequency of AC must be high enough so the half period will be shorter than the charge-up time of the dielectric…for most applications the frequency must be above 100 KHz” [Plasma Etching Outline]

Low frequency (LF, say 40-100 KHz)

[Optimization of IEP] says that while there are benefits to this range you are better off at 13.56 Mhz and compensating by using secondary plasma. Also: “Typically, low-frequency RF plasma systems can be built at a lower cost because they do not require the development of a complex coupling or variable matching network system. They can also be effectively utilized in applications where high-power applications are advantageous.”

[Optimization of IEP] claims that “ons that are energized at 40 KHz having a much higher energy level than those found at higher frequencies” (source: Chapman, B. Lucas Labs “Physical Electronics of Plasmas”). This is contradictory to EM waves which increase with energy as frequency increases…need to follow up on this. Anyway says this causes:

- higher temperature electrons which increases plasma temperature

- “higher energy ions, which can be beneficial for sputtering, but unwanted in some applications”

[Optimization of IEP]: “at this frequency, there is increased impedance, and low frequency systems are not typically designed for variable impedance matching. Consequently, there is a high-energy loss due to the elevated impedance present at this frequency. This loss results in a significant reduction in ion density”

13.56 MHz

[Optimization of IEP]: 13.56 MHz “…offers the advantage of the increased ion energies realized at 2.45 GHz without the complications of impedance matching”

[Optimization of IEP]: “Unlike 40 KHz, a well-designed 13.56 MHz system utilizes a variable capacitance- matching network. This network matches the impedance of the chamber and plasma to the power supply at 50Ω through a system of simple, variable capacitors. This permits greater power efficiency than that found in 40 KHz systems.”

[Optimization of IEP] says “An adequate amount of ion energy is an important component because it contributes to the sputtering capability of the plasma…The removal of fluorine and other contaminates such as oxides, metal salts, magnesium and lead are enhanced by the physical component of ionic bombardment…However, excess energy can result in unwanted results such as sputtering of the bond-pad site…Therefore, it is necessary to maintain a narrow energy range for control purposes. As Fig. 1 indicates, this is accomplished at higher frequencies such as 13.56MHz.”

mne: I had a phone call with a tech at plasma.de: Lower frequency systems (i.e. 40kHz) are typically used for plasma cleaning and the plasma energy is pretty low. For RIE systems and especially for corrosive plasma processes, the use of RF plasma (i.e. 13.56 MHz) with a matching network is recommended. With a low frequency system, it will work as well, but according to the tech, it will take way longer.

2.45 GHz Microwave

[Optimization of IEP]: At 2.45 GHz, the RF follows the skin of the chamber, which results in complexity for coupling. Consequently, the plasma must be generated in a separate region where impedance is maintained at constant factor and parts are processed downstream.“

But this creates a non-uniform plasma so people following methods to work around:

- turntable design: physically move parts around in the chamber. Effective but takes up space

- speed up movement of active species using larger pumps. “expensive solution and can result in reduced dwell time of active species which, affects the results of processes requiring more aggressive cleaning”

- Use oxygen “because of its longer life…However, many epoxies and metal leadframes are prone to oxidation, which eliminates the viability of this option”

Polymer formation

Problem: perfluorocarbons (PFCs) can form polymers

Why? Ex with CF4: after reacting with Si forms CF3 radical. Then will want ot react with others to form polymyers (ex: C2F6?) to stabalize. Repeats to grow the molecule. Presumably as long as these stay small enough they remain volatile but if they get too far they begin to buildup.

[Plasma Etching Outline]: Molecule's Fluorine-to-Carbon ratio (F/C) plays key role in determining how the gas will behave. Graph on page 23 seems to indicate 3 or 4 are pretty solid numbers. Otherwise you need to increase ion energy to favor etching over polymer formation (is this simply heating the polymers to favor evaporation?)

[Plasma Etching Outline]: “Addition of oxygen to the plasma chemistry increases F/C ratio and reduces polymer formation” Guess it burns C into CO2. Warns to watch out for things that get eaten in oxygen plasma like photoresist

[Plasma Etching Outline] mentions another problem with polymers is that they lead to general chamber contamination

[Plasma Etching Outline]: “Properly controlled polymer deposition can allow anisotropic etching with otherwise purely chemical isotropic etch chemistries.”

Inert gases

Should be selected based on chamber pressure and other parameters…Ar is good general purpose

[Plasma Etching Outline] on Ar: “added to ion enhance the etching process (I.e. reactive ion etch)”

Active gases

H2

[Plasma Etching Outline]: “reduces fluorine concentration by combination to form HF”

H2 is useful for making SiO2 etch faster than Si, see that section for details

O2

Used for ashing organics

[Plasma Etching Outline]: “Increases fluorine concentration by combining with carbon (CO, CO2) which would otherwise bond to fluorine (reacts with CF3 to liberate F)”

Adding O2 will make Si etch faster than SiO2, see that section for details

N2

CHF3

Common synonyms

- ACS number: 75-46-7

- CHF3

- Fluoroform

- Trifluoromethane

- Freon 23

- Genetron 23

- R23

There are semiconductor and regridgerant grades of this gas

Properties (mostly from Airgas MSDS)

- Density: 2.946 kg·m-3 (gas, 1 bar, 15 °C)

- 70.02 g/mole

- 0.179 lb/ft*3

Availibility:

- sigmaaldrich (SA)

-

- $595.00 / 227 g

- ≥98%

-

- Airgas

- 5 lb semiconductor: http://www.airgas.com/browse/productDetail.aspx?Category=316&product=REFR23S5

- 5 lb electric grade: http://www.airgas.com/browse/productDetail.aspx?Category=316&product=REFR23E5

- Didn't get follow up on complete pricing, but generlaly much more reasonable than SA

- Madco (local supplier) did not carry it

Misc:

- CHF3 Dual-Frequency Capacitively Coupled Plasma by Optical Emission Spectroscopy

CF4

Freon 14

Machine types

Parallel plate etcher

The type of machine used for anisotrophic etching

DIY

Started experimenting with a DIY unit. After playing around with a few designs, settled on using a chemistry reactor lid on top of a 3/8” aluminum plate. Gas is fed in via 24/40 jointed glass connection to center of assembly

Aluminum plate is on ceramic standoffs so that I can adjust polarity as need be (typically + voltage).

Power supply: LKB 5kV, 150 mA variable output electrophoresis power supply. Current, voltage, and wattage limits

Early tests showed that strike ring is definitely necessary. Otherwise plasma forms by striking the IC to ignite and causes severe damage

Pressure must be low enough to form a real plasma and not just spark around

Millipore analog MFC's

Barrel etcher

Because its non-directional its generally only used for cleaning wafers in fabrication. That is, its less useful for delayering chips becaues it will undercut pretty bad

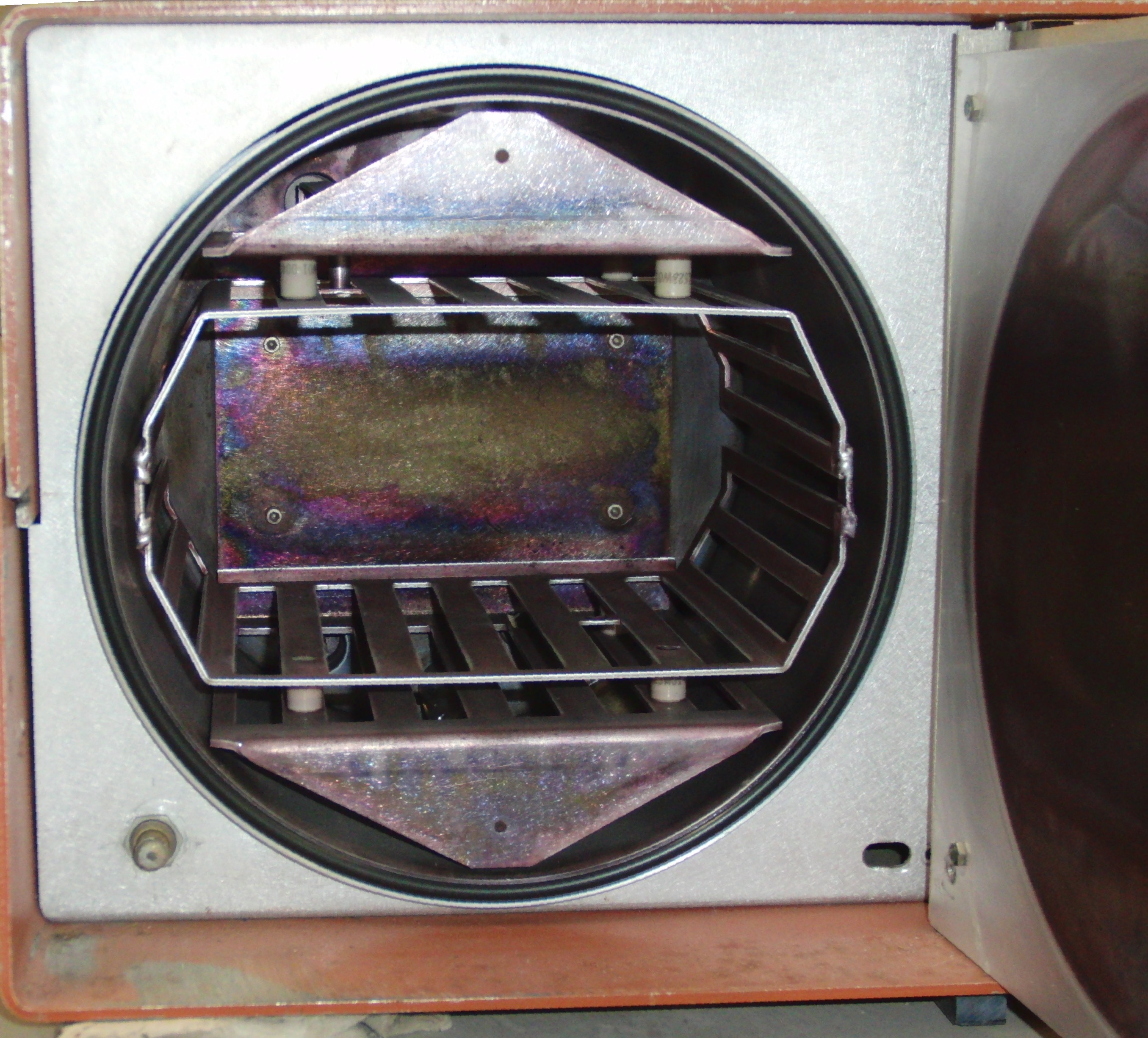

Example unit (more pictures here):

Downstream etchers

[Plasma Etching Outline]: “Plasma is formed in a cavity which is separated from the etching chamber. Wafers are shielded from bombardment. Only radicals reach wafers. Etching is completely chemical and isotropic High selectivity achievable; Si:SiO2 = 50:1 Plasma may be generated by RF or by microwave”

Materials

SiO2

[Plasma Etching Outline]: Adding O2 will make Si etch faster than SiO2: “Adding O2 can increase etch rate if Si (ie increases F/C ratio by reacting with Carbon. By decreasing the carbon content, the oxide etch rate decreases and subsequently increases the Si etch selectivity over oxide.”

[Plasma Etching Outline]: Adding H2 will slow down etch but will make SiO2 etch faster than Si: “Addition of H2 decreases the effective F/C ratio (by reacting with F to form HF). This decreases the formation of SiF4 and subsequently decreases the etch rate of both Si and SiO2.

- The lower F/C ratio will enhance polymerization on silicon surfaces and inhibit etching.

- On SiO2 surfaces, the presence of O2 in the film locally reacts with C (to form CO and CO2) and minimizes polymerization.

- Subsequently the Si etch rate decreases, relative to the SiO2 etch rate which improves the selectivity of SiO2 versus Si.”

[Plasma Etching Outline] etch rate chart:

| Gas | F/C | SiO2 / Si Selectivity |

|---|---|---|

| CF4 | 4 | 1 |

| C2F6 | 3 | 3 |

| C3F8 | 2.7 | 5 |

| CHF3 | 2 | 10 |

[Plasma Etching Outline] lists the following as commercially viable etch mixtures (not CHF3?):

- CF4

- CF4 + H2

- HF

- CCl2F2

- C3F8

- C2F6 + H2

Beck Process 5

Seems like a good reasonably non-toxic etching process

[Beck 111]

“Etching of the Isolation Oxide (IOX) (between Polysilicon and Aluminium)”

Parameters:

- Type: anisotropic

- Gas: CHF3/Ar: 25/25 sccm

- Pressure: ~20 mTorr

- HF power: 200 W

- DC bias: 360 V

- Etch rate: 35-40 nm/min

Etch rates:

- Nitride: 12 nm/min

- Si: 2.6 nm/min

- Al: 2.6 nm/min

- SiO2: 39 nm/min

- “Selectivity Oxide: Silicon = 15 : 1”

Cu

As explained below, don't remove Cu by RIE: remove it mechanically or chemically.

[Plasma Etching Outline]: “Copper does not form any volatile compounds with known plasma etch gases, and therefore cannot be RIE etched. Copper can be sputter etched, but this technique has no selectivity. Contamination of the fab with copper is serious concern. The Damascene process has become an attractive enabling method for patterning copper by CMP.”

Al

- Anisotrphic etching requires inhibotors/addaditives to main Cl2 feed like CCl4, CHCl3, SiCl4, BCl3

- Water is bad. Add BCl3 or SiCl4 to suppress it

- 3 nm metal oxide film must be punctured to etch metal

- Al2O3 is extremely chemically resistant. Use physical bombardment to remove it initially

Off the shelf gas sources

Canned air

Common gases:

- 1,1-difluoroethane

- C2H4F2

- 1,1,1-trifluoroethane

- C2H3F3

- 1,1,1,2-tetrafluoroethane

- C2H2F4

Refridgerant gases

Because these are widely availible fluorinated gases worth taking stock

http://en.wikipedia.org/wiki/List_of_refrigerants

Notable gases (PFC's):

- Decafluorobutane / R-3-1-10 / C4F10

- Dodecafluoropentane / R-4-1-12 / C5F12

- Hexafluoroethane / R-116 / C2F6

- Octafluorocyclobutane / R-C318 / C4F8

- Octafluoropropane / R-218 / C3F8

- Tetradecafluorohexane / R-5-1-14 / C6F14

- Tetrafluoromethane / R-14 / CF4

References

- OPTIMIZATION OF ION AND ELECTRON PROPERTIES IN IC PACKAGING APPLICATIONS (Optimization of IEP): http://www.nordson.com/en-us/divisions/march/support/Literature/Documents/1-optimization.pdf

- CHF3 Dual-Frequency Capacitively Coupled Plasma by Optical Emission Spectroscopy: http://cpl.iphy.ac.cn/EN/article/downloadArticleFile.do?attachType=PDF&id=43429|

- Plasma Etching Outline: http://web.utk.edu/~prack/Thin films/Etching.pdf