This is an old revision of the document!

Table of Contents

It is often desirable to remove bond wires. Common reasons include:

- Leaving a clean surface to re-bond the die into a new package

- Providing a flat surface so the die can be mechanically polished

- Providing a clear view of the die surface for imaging

TLDR:

- Gold: for best results, use a ladle to dip the die in a solder pot

- Aluminum: pluck or briefly sonicate in a corrosive solution

- If you want quick results and are okay risking some damage, use tweezers to pluck wires off

Mechanical methods

Ultrasound

Strong sonication has been known to shake off wire bonds. This often damages or destroys the bond pad.

Shearing

The most simple way to remove bond wires is to simply knock the ball off the pad with sideways force using a pair of plastic tweezers. The flat end of a scalpel blade tip often works as well (using the blade will cut through the ball and leave half of it attached to the pad).

While this is fine for imaging, often a chunk of metal and/or silicon is ripped out along with the wire, leaving a pad which is useless for re-bonding.

Chemical methods

Aluminum bond pads

Weak nitric acid eats aluminum. Since most bond pads are aluminum, one can simply put a chip in weak nitric acid and all the bond wires will fall off. Don't leave it in too long as it will start to etch under the overglass and eat top metal. Aqua regia also works and is much more aggressive as it will work even when weak at room temperature. As with shearing, this method destroys the pads resulting in a die which cannot be re-bonded.

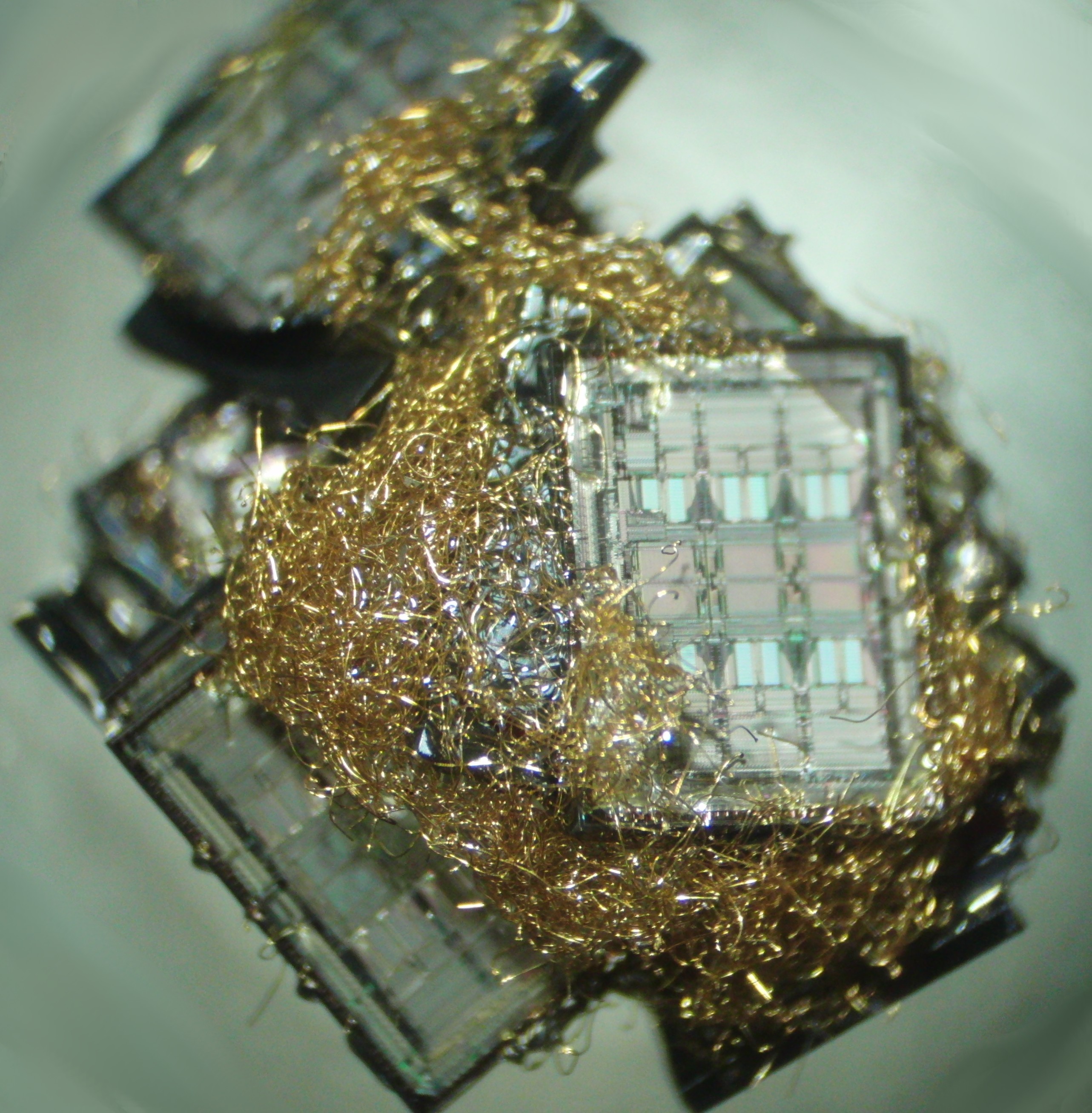

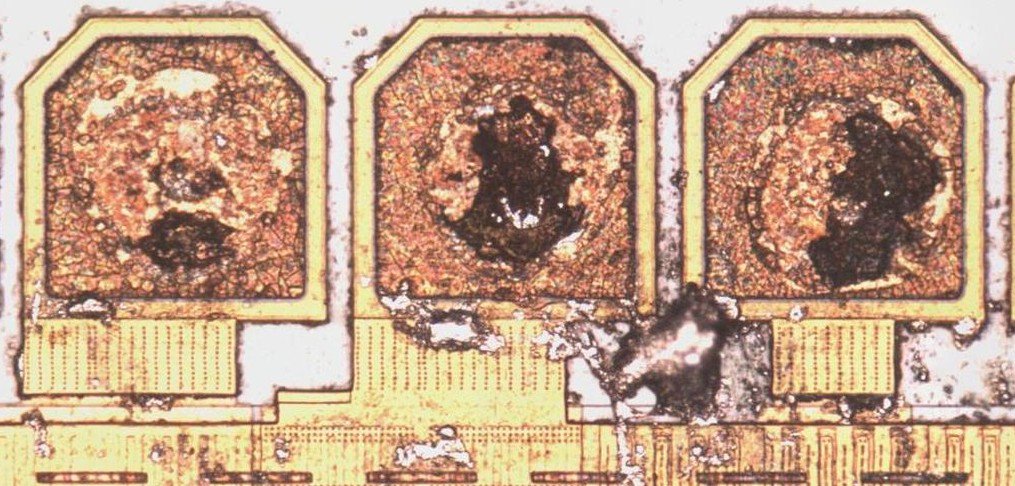

Example damage from aqua regia. Before (Xilinx XC2064-70):

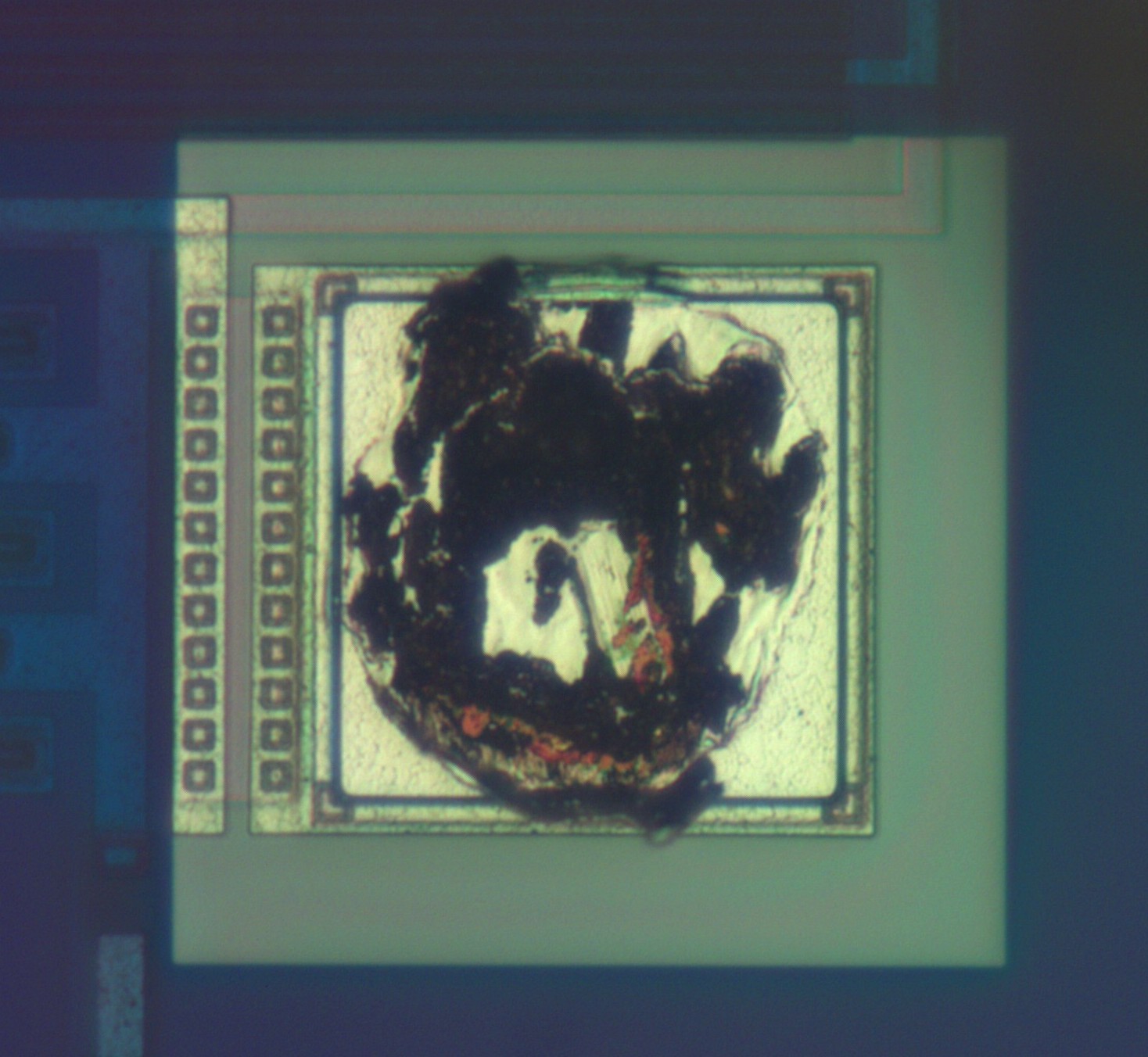

After:

The discolored area above and into the the left green area is from acid seeping relatively far into the die. Similarly, there is a second patch with excessive acid damage near the bottom. Note how the center of the die typically does not sustain any damage due to overglass passivation.

Copper bond wire

Copper bond wires are difficult to preserve during decapsulation and will disintegrate at the slightest provocation. If by some miracle a bit of copper bond remains on the pad, concentrated nitric acid will remove it cleanly with minimal damage to aluminum bond pads. This leaves a very clean substrate which is perfect for re-bonding. There is typically a shallow crater in the bond pad caused by pressure from the previous bond, but this does not appear to prevent successful re-bonding.

Gold bond wire

Gold mining literature reveals a number of ways to dissolve gold. Gold mining tends to be more selective to stay cost effective which is what we want. NaCN tends to be the chemical of choice with thoria less toxic but less economically viable.

Tin

Lead

The most effective way to remove gold bond wires so far has been hot lead-gold amalgam. Sometimes two metals can be melted together to form an alloy at much lower than their melting point. Gold and lead form such a mixture.

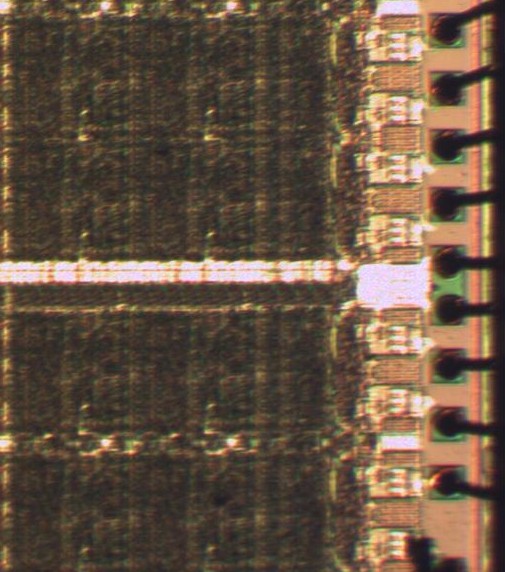

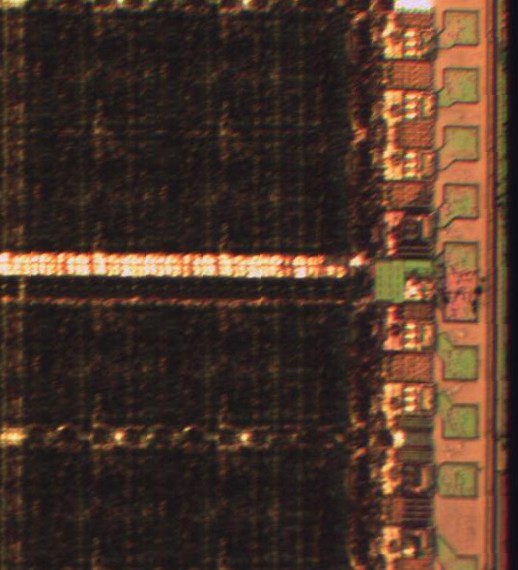

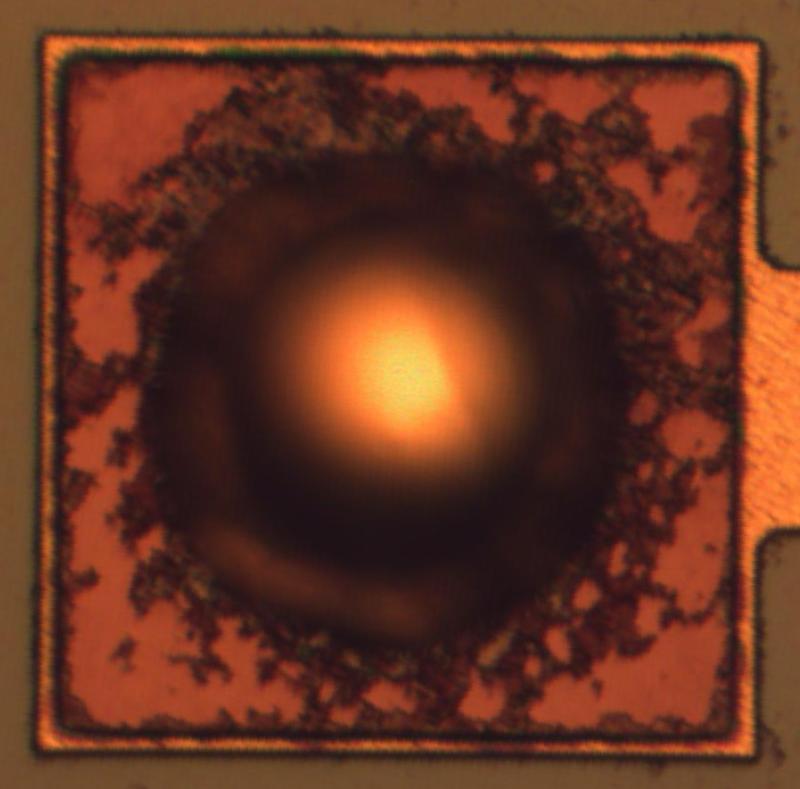

Pad from same chip with bond wire still attached:

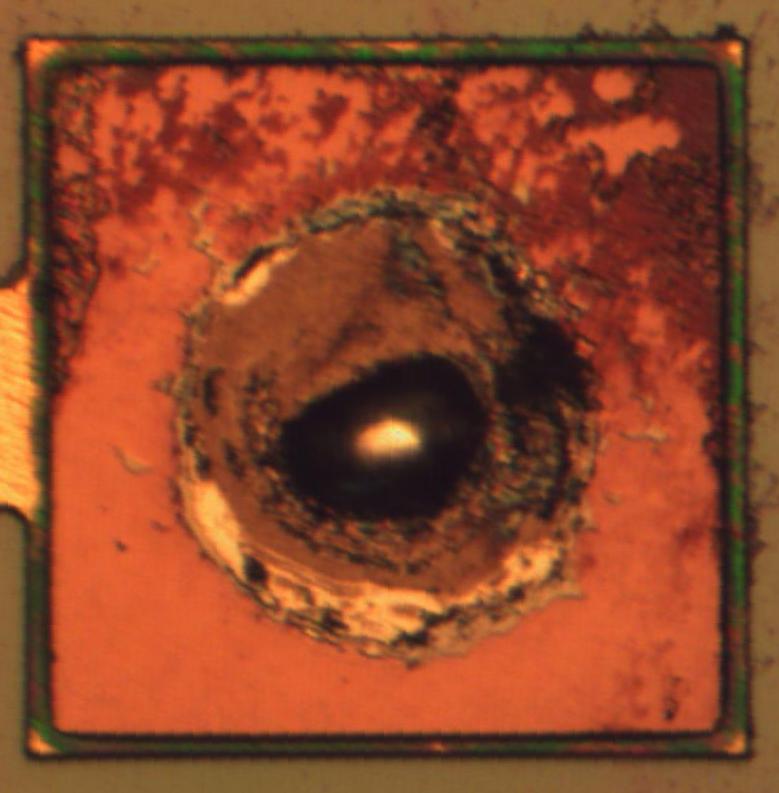

Pad with bond wire partially dissolved (note the solder tinning):

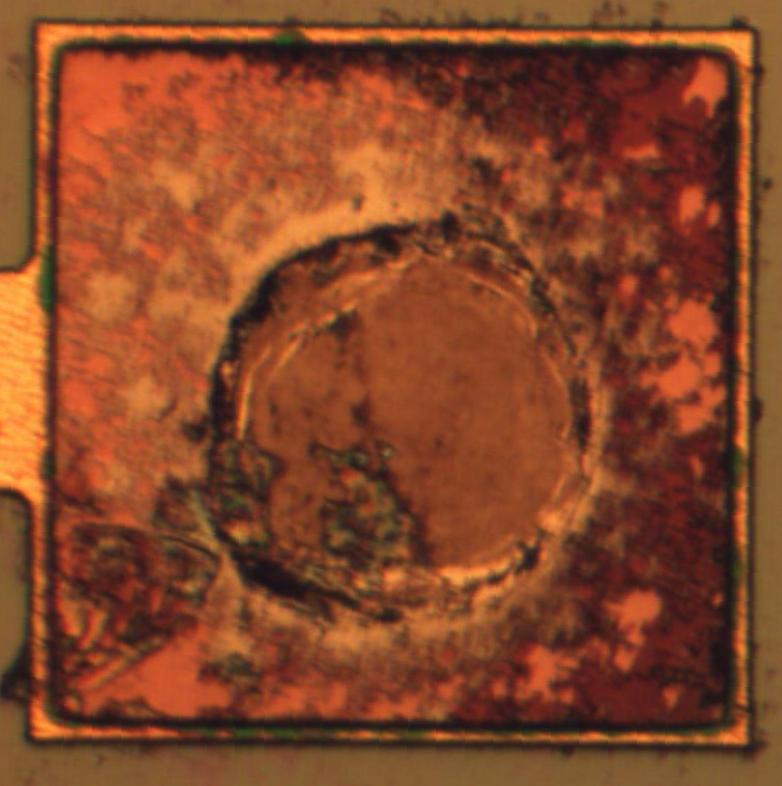

Pad with bond wire fully dissolved:

mcmaster solder pot

Model: KD-350 150W

- 150W

- 480C max (60/40 melts at 188C)

Thermometer: GDEALER DT8

- Measurement range:58℉ to 572℉(-50-300℃)

- Accuracy: ±1℃(±2℉) between -50~200℃(-58℉~392℉),±2℃/℉ more than 200℃/392℉

Watt meter: P3 International P4460 Kill A Watt

Amazon notes:

The Twinkle Bay Lead Free Solder Pot is ideal for tinning the ends of stranded wire leads, pre-tinning small electrical parts, re-tinning soldering iron tips and dip soldering small circuit boards. Pot solder capacity: 500g / 17.6oz Item weight: 455g / 16oz Package weight: 515g / 18.2oz Pot solder Diameter: 50mm / 1.97in Item Size(L x W x H): 150 x 90 x 65mm / 5.9 x 3.5 x 2.2in Rated voltage: 110V Rated power: 150W Min approx temperature: 200°c Max approx temperature: 480°c Note: The grounding/earth wire must be connected before used in order to protect the circuit from static electricity. It's normal to appear a little smoke from the electric core at the first time to use. Reasonable operating temperature 300-350°c (Stalls about 4-9) can prevent man-made aging of tin stoves. Must turned off the power when you left in order to keep the safe.

mcmaster procedure 10/27/2016

This process works very good. Basically:

- Clean die

- Place a drop of flux onto ladle

- Place die onto ladle

- Dip ladle into solder

- Let sit for 30 seconds

- Remove ladle

- Clean die in acetone (leave it on the ladle)

- Inspect die under microscope. Clean and repeat if not fully dissolved

- Sonicate in cold WFNA for 1 minute

- Acetone removes most but not all flux

- Clean in acetone

This technique has very quick turnaround time (other than solder warming up) and is gentle on the die

Open question / problem: sometimes wires don't wet, usually if there is just a small stub left

- Re-adding rosin and re-dipping doesn't help

- Cleaning and re-dipping does help, but not massively

- Idea; sonicate in rosin, then dip

- Idea: gently press into rosin soaked cloth, then dip

I made my ladle from a scrapped aluminum case. Then put a few layers of heat shrink on the handle and reduced the handle diameter to reduce conductivity. Still, it can only comfortably be held for short periods of time and usually requires insulating gloves. (more than the white ones shown)

Old flush is more difficult to clean off. Therefore, change / clean beaker if its getting dirty.

mcmaster procedure 04/29/2013

Equipment

- 50 mL glass beaker

- Ultrasonic cleaner

- 100 mL PTFE beaker

Materials:

- Syringe of solder paste

- Acetone

- Aluminum foil

- Carbon fiber tweezers

Procedure:

- Tilt hot plate such that solder will flow to one side of beaker

- Heat hot plate to solder melting point but not above

- On mine this is power level 6

- Depends on specific solder used and other factors

- Place die face up at glass beaker edge

- Dispense solder paste on die

- Be generous: cover it well

- Gently place older solder on top of pasted die

- Cover glass beaker in aluminum foil

- Place glass beaker on hot plate with die side downhill

- Wait for solder to melt. The die should be completely covered in solder

- About 2 minutes in my setup

- Slosh solder around a little to ensure no voids

- Flux should keep die in place

- Let cook for at least 5 minutes with solder covering the die

- Turn beaker 180 degrees so that solder rolls off of the die

- Quickly: remove aluminum foil from beaker

- Quickly: dump solder out of beaker

- Aluminum foil works well: solder easily comes off

- Quickly: pickup die with tweezers and drop in PTFE beaker

- If you aren't quick enough die will stick to tweezers (rosin is solid when not hot)

- Remove it by soaking and/or sonicating tweezers in beaker with acetone

- Sonicate die with acetone for 3 minutes

- Change acetone

- Sonicate die with acetone for 3 minutes

- Inspect die for undissolved gold (usually shows as silver solder lumps on bond pads). Repeat procedure if sufficient quantity remains

- When done properly all gold should be removed

- Place die back in storage vial

Notes:

- Do not heat solder more than necessary: higher temperatures will cause flux to burn instead of melt

- Clean glass beaker with sonicated acetone when done

- Use enough solder to comfortably cover the die but you only need enough paste to flux/start it

- Also experimented with heating in Al foil but beaker method gives much more repeatable, safer result

- Do not do anything that would rapidly cool the beaker or die

- I cool the beaker with forced air

- Grabbing hot die will warp tweezers. Use dedicated pair

Al foil

Idea was to encase die in paste and fold it into aluminum foil. Then heat it strongly and remove the cleaned die. However, the foil can scratch the die and does not give repeatable results. Although this method is quicker, the beaker method above is more thorough and less prone to damage

Soldering iron

NOTE: not recommended since its much more work and easily scratches die

By repeatedly adding solder to dissolve gold and then removing the solder the gold is dissolved and eventually removed.

Procedure:

- Reduce bond wires to stumps by carefully bending back and forth with tweezers

- It should take 4 or 5 bends

- An inspection microscope will help

- Don't pull, you'll risk ripping out silicon

- Place solder paste on bond areas by dragging a solder paste drop across the padframe. An inspection microscope will help

- Heat solder paste by bringing soldering iron close to chip. Bond wires should now be tinned

- Place a larger drop of solder paste on the chip and heat. Drag the soldering iron past the edge of the chip (but not on top as it would cause damage) such that solder is forced on top of the chip but is still attached to the iron. As it moves back and forth it should heat the gold and dissolve it

- Repeat until all gold is removed

Mercury

At least at room temperature (and even I (JM) dare not heat it) it performed much worse than the solder paste method. Even after soaking die for an hour I could not completely remove all the gold. I sonicated it in water which removed the liquid element but left behind a solid gold-mercury mixture.

Advantages:

- No fluxing required: much cleaner

- Room temperature: no risk of thermal damage

Disadvantage

- Mercury health risks

- Difficult to completely remove gold

- Dissolves gold slower than hot lead

Wood's metal

Field's metal

JM has some on order to try