Table of Contents

Optics cleaning gives a lot of general guidelines on cleaning, consider consulting a textbook for more detail.

Choice of solvent

Popular cleaning agents include:

- Deionized (DI) water

- Alcohols, especially isopropanol (isopropyl alcohol) and ethanol

- Acetone

JM chip cleaning procedure as of 03/09/2013

- Fill 10 mL glass vial w/ polyprolyene cap about 2/3 full with acetone

- Glass has better acoustic coupling than plastic and removes a lot more

- Place chip in above vial and sonicate for 1 minute

- Empty acetone out into second identical vial, leaving the chip behind

- Fill 50 mL polypropylene (PP) vial with 30 mL water + detergent

- glass vial would probably work just as well if not better

- Shake chip from glass vial into PP vial

- Sonicate for 1 minute

- Pour solution from 50 mL PP into second identical PP, leaving chip behind

- Flood chip with water in vial, letting it fill past the top and refilling a few times until all suds are removed

- Fill another 50 mL PP with 30 mL acetone

- Shake chip from empty suds vial into final wash acetone vial

- Sonicate for one minute

- Pour most of acetone, leaving a few drops, into yet another 50 mL bottle

- With lid closed, shake chip so that its near mouth of vial with die facing up

- Alternatively carefully slosh it up there before pouring

- Use carbon fiber tweezers to grab die and place face up in PP sealable petri dish

- Seal petri dish

Other notes:

- All vials are labeled to easily tell apart solutions

- The final acetone vial should have a flat surface near the lid to make it easy to grab

- Don't use the same acetone solution or vial for the initial and final wash

Ultrasound

Acetone bath + ultrasonic cleaning (ultrasound) are effective to remove latent debris and generally is the preferred workhouse method in a professional setup. If ultrasound is not available, first try pressurized solvent from a squirt bottle or pipette.

Procedure

- Literature [1] indicates a minute in ultrasound should be sufficient to clean the die

- 1 minute in acetone (remove bulk debris)

- 1 minute in suds (remove polarized debris)

- 1 minute in acetone (high purity “dry” clean)

I use a setup like this to keep which vial holds which sample straight:

Each type of clean has two bottles, one active with chip and solvent and one empty. That way as I finish with a sample it can be poured into an equivalently clean and labeled bottle to easily retrieve the sample. Often I slush the die to the side for easy retrieval and then shake it into the next. When one tube is missing from the rack its empty slot holds the labeled vial holding the die so that multiple dies in the pipeline don't get mixed up.

Notes

- Choice of sample holder?

- Power level required?

- Heating required?

- Choice of solution? DI water? Acetone?

Advantages

- Relatively inexpensive if many samples are done

- Low chance of damaging the die?

- what if we accidentally positioned it such that surface vibrated against the circuitry?

Disadvantages

- Higher initial cost than other techniques presented here

- Takes a few minutes (but hopefully you aren't THAT impatient)

Choice of container

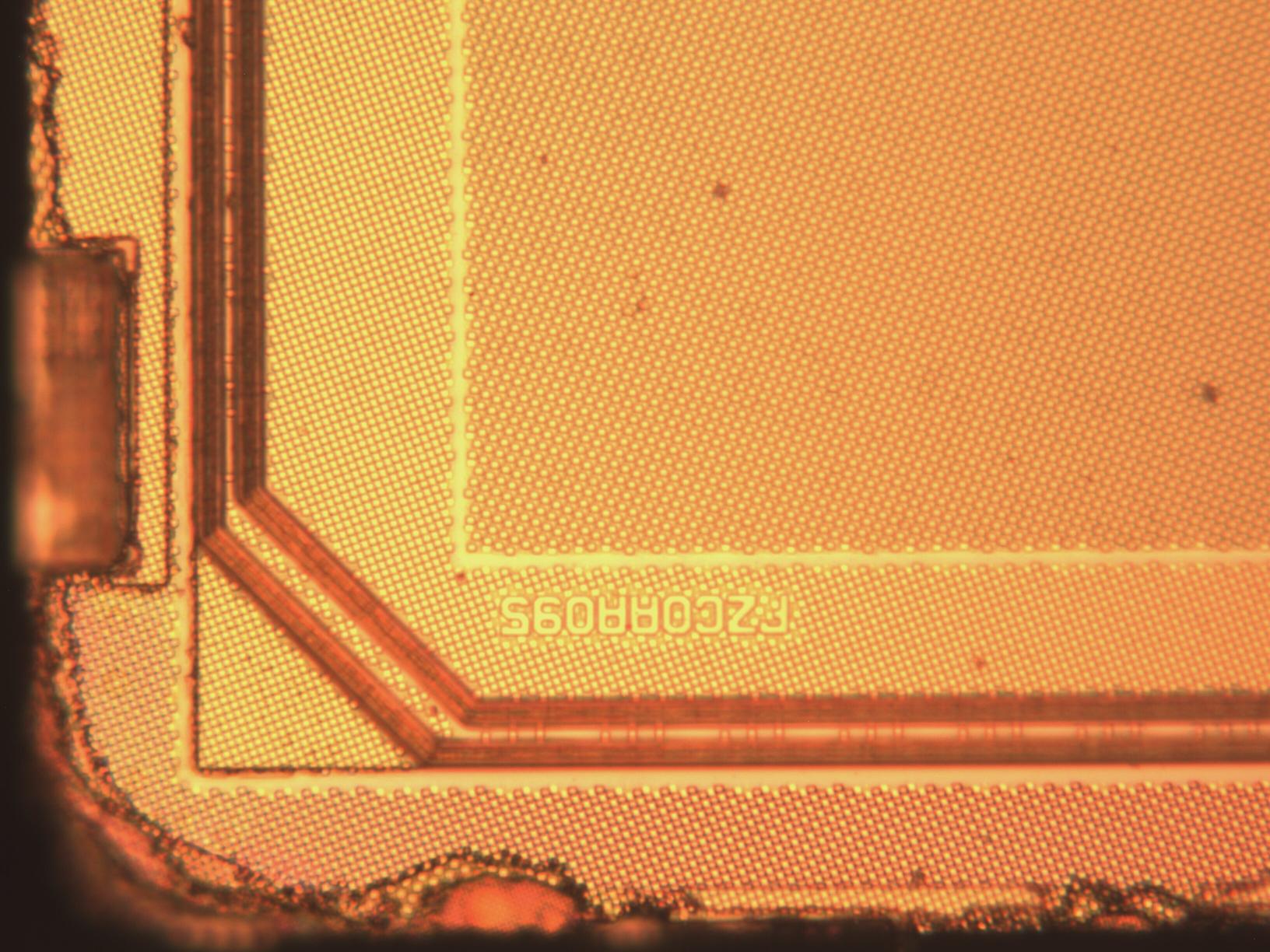

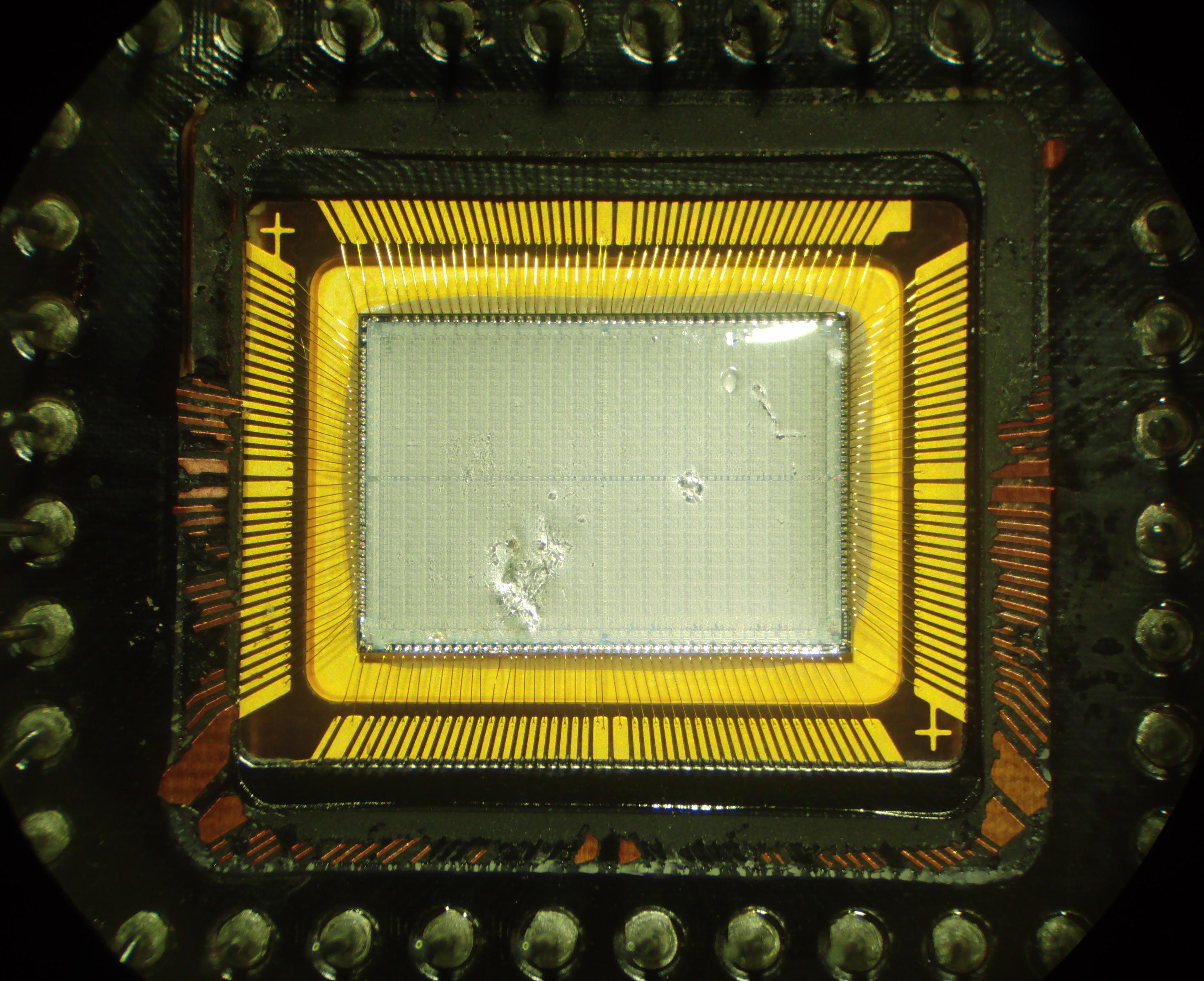

Using a glass container with strong ultrasound cleans the chip well, but may be stronger than needed. Above left: chip from lot that was not ultrasonic cleaned. Above right: chip from same lot that was ultrasonic cleaned for 1 minute in glass 10 mL vial. The corners have been chipped off

Case study

The most extreme contamination you are likely to encounter is from grinding a TO-3 or similar open:

After blowing off you'll still have massive contamination:

Washing with water followed by acetone will help considerably (sample picture taken while still covered with acetone which is somewhat cheating since it makes it look better):

But there are still a lot of particles. These can be brought down much lower still by ultrasound:

Above was taken after 8 minutes (Beck indicates 1 minute should be sufficient, did not take multiple pictures to show length effect) ultrasound, water wash, and then acetone wash. If the sample was needed really clean it could be put through another run. Of course normal washing will continue to improve the sample as well, but *much* slower.

Pressurized solvent

A good starting cleaning technique since its inexpensive, quick, and may even be sufficient for final analysis depending on how decapsulation was done. Use a syringe or small tip pipette to shoot a jet of solvent at the die.

Procedure

- Using a pipette, rinse bottle, syringe, or other pressurized solvent source, rinse the surface of the die

- Repeat as needed until clean

Notes

- None

Advantages

- Inexpensive

- Low chance of damaging the die

Disadvantages

- Often will not clean materials easily removed by other techniques

- Pipette and syringe materials may leach into the solvent

Mechanical agitation

Uses techniques similar to those for cleaning optics.

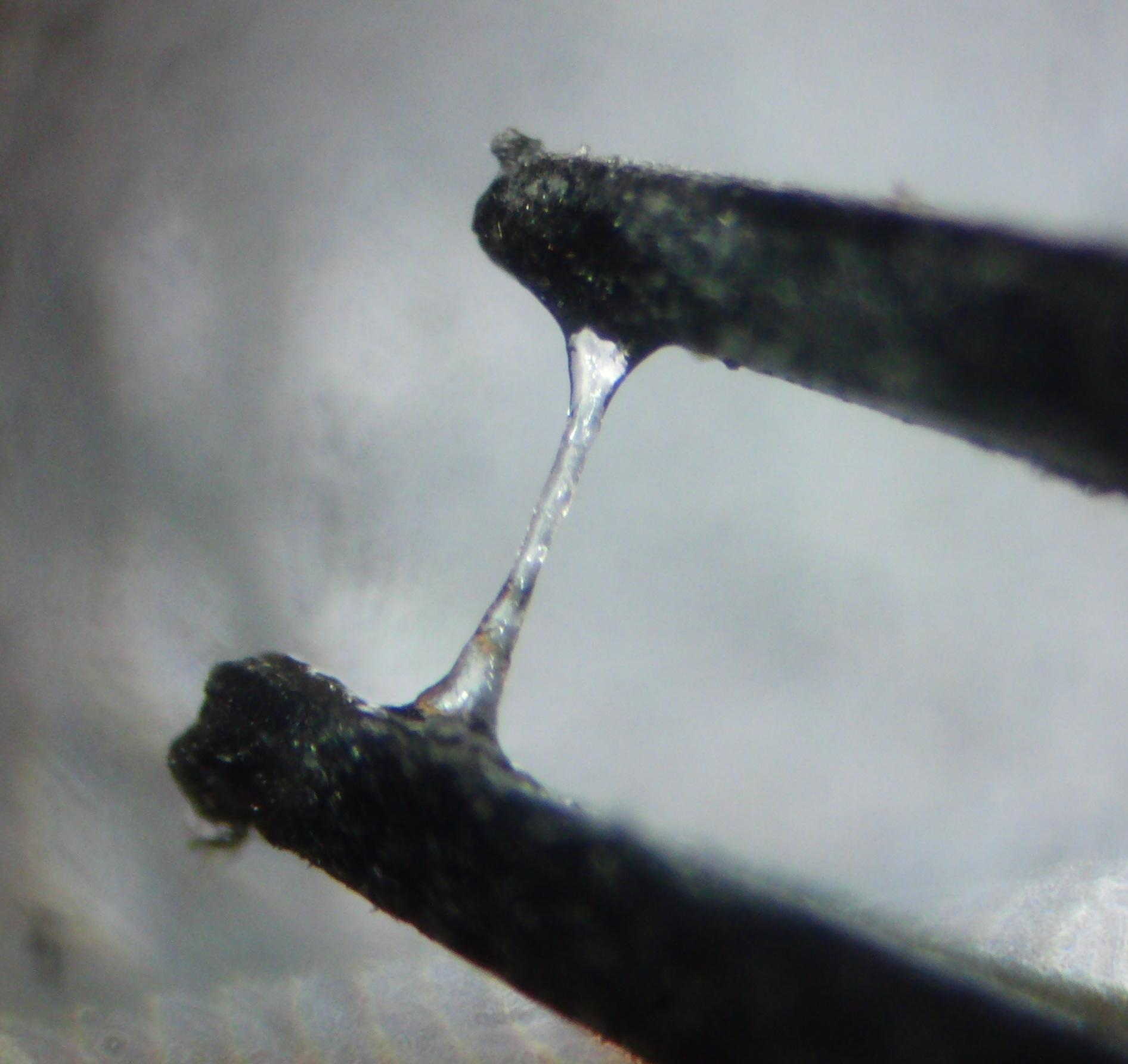

Lens tissue is preferred since its lint free and known to resist solvents like acetone without leaving residue. Lens tissue close up:

Procedure

- Using a cleaning cloth of some sort, fold it until it is mildly stiff

- Wet with solvent

- Drag it across the surface. DO NOT use your fingers to apply pressure

- If is not sufficient, try some more at the same stiffness, or fold as necessary to increase cleaning power

Notes

- Careful to not confuse undissolved epoxy for contamination. It may not come off easily and can potentially scratch the surface if forcefully dragged across

- Do not tear lens tissue. Use it in whole sheets and move it around if necessary. Tearing it will release particulates

Advantages

- Readily available and inexpensive equipment

Disadvantages

- Higher chance of damaging the die

- Will destroy bond wires, unsuitable for live analysis

Mild abrasive

Use a mild abrasive (ex: toothpaste) as a buffer to apply force to die surface.

Contaminants

Dust

Generally an acetone rinse should take care of dust.

Can be blown off with a sufficiently clean air supply but generally these are hard to come by. For example, optics cleaning tends to recommend against using compressed air cans. They said that if you insist you must use them upside down to allow particulates to settle and must spray for a bit elsewhere first to clear out the system.

Epoxy residue

After epoxy decapsulation the chip may have bits of epoxy still hanging around. Sonicating in acetone should clear it up with most epoxies. I've found a few compositions that don't but I'm not clear on what the difference is. In these instances pressurized acetone from a syringe tended to work well. This is also a good method to remove hard to take off grit that acetone will not get. If you are still having issues considering briefly soaking in clean RFNA or hot clean H2SO4 as the epoxy might not be fully dissolved.

Acid

After decapsulation the sample will have traces of acid on it that will likely corrode it over time. Use the standard procedures discussed on the epoxy decapsulation pages: acetone wash to remove bulk acid, soap and water for a deeper clean and to remove salts, and finally an acetone wash to dehydrate the chip.

Fingerprints

Shame on you if you picked up a die with your bare hands but things do happen. Acetone does not clean off fingerprints very well but soapy water does. The above picture was taken after putting a fingerprint on a slide and sonicating in acetone for a few minutes. It has little to no effect. Fingerprint oils do not respond to polarized light (ie will black out).

Polyimide passivation

General reccomendations:

- Oxygen plasma is probably best if you have access to it

- If you can deal with safety issues, ethylendiamine may be next best

- Fuming nitric aicd works but takes a while. This can potentially cause chip damage but shouldn't hurt Cu/Al if you keep the concentration high

- Piranha eats it quickly but it eats other metals nearly as quickly so its probably best avoided

Ethylendiamine

“find a polyimide layer that was not entirely removed by HNO3 but which can be dissolved with ethylendiamine” (ref)

Rest from [Beck 23]

Procedure:

- Use straight (how much?)

- 100° C for 15-60

Ethylendiamine + hydrazine monohydrate

“Ethylenediamine readily reacts with moisture in humid air to produce a corrosive, toxic and irritating mist, to which even short exposures can cause serious damage to health (see safety).” [Wikipedia]

From [Beck 23]. Use this if plain ethylendiamine does not work. Unclear if it has a higher corrosion potential, but heed the safety warning

Procedure:

- Mix (how much?)

- 7 mL 80% hydrazine monohydrate

- 1 mL ethylendiamine

- 100° C for 15-60?

Notes:

- WARNING: spontaneous combustion can occur over 120° C

Ethylendiamine + hydrazine monohydrate

[Beck 23]

Procedure:

- Mix

- 3 mL ethylendiamine

- 1 mL 98% acetic acid

- Cook 120-130° C for 10-30 minutes

Notes:

- Mix slowly (or what?)

- Stir vigorously

Caro's acid

[Beck 23]

Procedure:

- Mix

- 7 mL (98%?) H2SO4

- 1 mL 30% H2O2

- Cook at 80° C

Notes:

- Seems like this is same thing as Piranha solution? In any case see notes there

Fuming nitric acid (FNA)

When decapping part with WFNA/RFNA the amide layer will usually be simply dissolved [Beck 23, personal experience]

Beck mentions “imide”?

Oxygen plasma

“Polymides can usually be removed gently without leaving residues by incineration in the oxygen plasma” [Beck 23]

Dimethyl sulphoxide + ethanolamine

[Beck 23]

Procedure:

- Mix

- 3 mL dimethyl sulphoxide

- 1 mL part ethanolamine

- Cook at 110° C

WARNING:

- Spontaneous combustion above 120° C

Gel passivation

Chip with some damaged gel:

Some chips have what I believe to be silica gel passivation. Unfortunately, this can be rather difficult to remove chemically without damaging the chip. However, it can be wiped off easily if you are fine destroying bond wires.