This is an old revision of the document!

Table of Contents

Misc:

- CDIP: Ceramic DIP

- CERDIP: glass sealed ceramic DIP

- Dual in-line package (DIL) or(DIP) Dual Inline Package: two 0.1“ pitch rows

- QIP: Quadruple in-line package: “like DIP but with staggered (zig-zag) pins” (wiki)

- SDIP: Skinny DIP: “standard DIP with .1” pin spacing, rows .3” apart“ (wiki)

- ZIP: Zig-zag in-line package

- MDIP: Molded DIP

- PDIP: Plastic DIP

- SIP: Single in-line package

- Round TO (transistor outline)

Pin grid array:

- OPGA: Organic Pin Grid Array

- FCPGA: Flip-chip Pin Grid Array [3]

- PAC: Pin Array Cartridge [10]

- PGA: Pin grid array (also known as PPGA) [1]

- CPGA: Ceramic Pin Grid Array [3]

Single inline (SIL) package

Dual inline (DIP) package

Plastic DIP (PDIP)

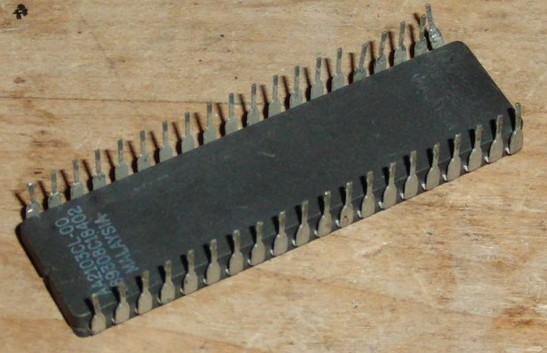

These are actually made of epoxy and glass. They come in varying number of pins and widths. Pins are on a 0.1” spacing and package widths are typically seperated by 0.3“ or more in 0.1” increments.

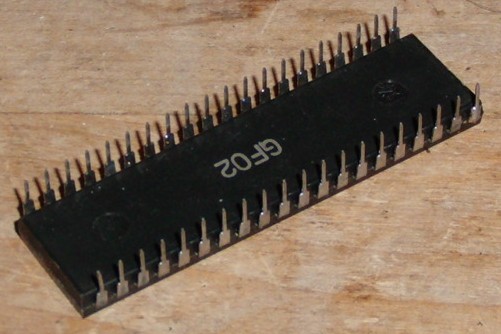

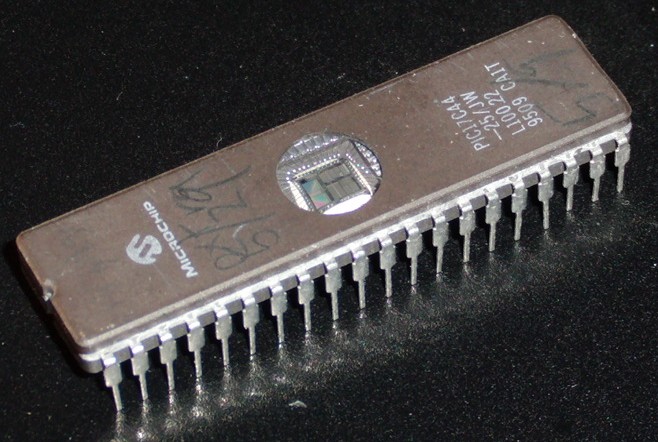

0.6“ PDIP-40 (UMC UM82c55A), a pretty typical DIP:

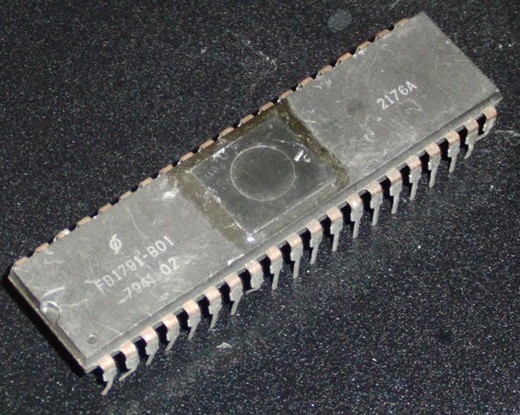

Older style chip with chip large die cavity (added after molding?):

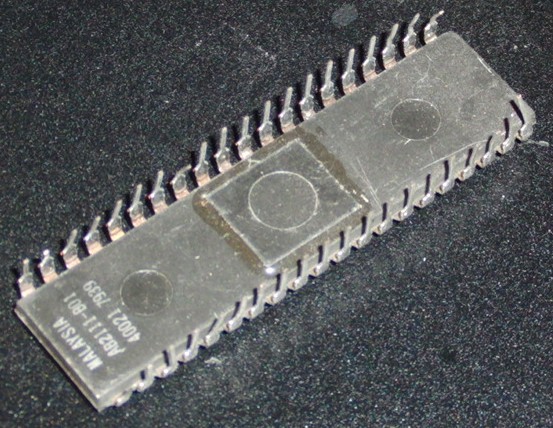

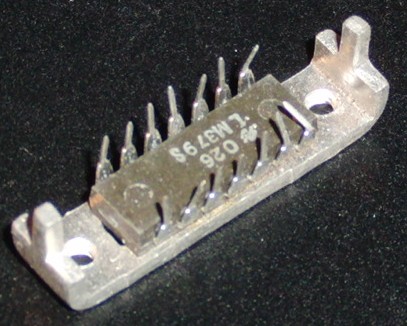

One major disadvantage of PDIPs is their relatively poor heat conduction being made primarily of glass. A 0.3” PDIP-14 with heatsink:

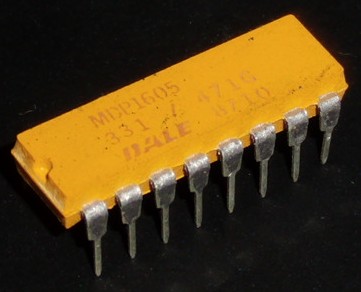

Colored PDIPs are uncommon but do exist. The most common are resistor networks which are typically orange. 0.3“ PDIP-16 (Dale MCP1605):

True Plastic DIP

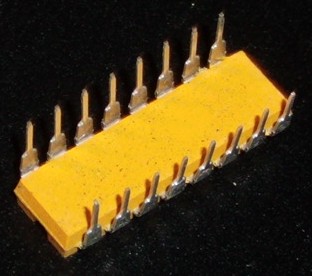

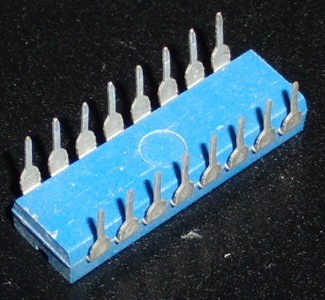

PDIPs made of plastic do exist but they are rare. They are typically used for resistor networks. However, as resistor networks put off heat and epoxy generally takeas heat better than plastic, even most resistor networks are encapsulated in epoxy instead of plastic. Generally these are colored such that they stand out very obviously from epoxy or ceramic chips. I'm not sure of any standard name for these so I'm going to call them Plastic PDIP (PPDIP) since their namesake was taken by PDIPs.

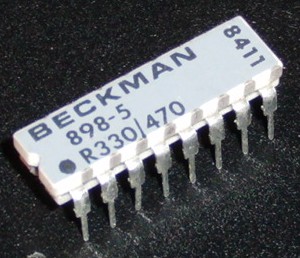

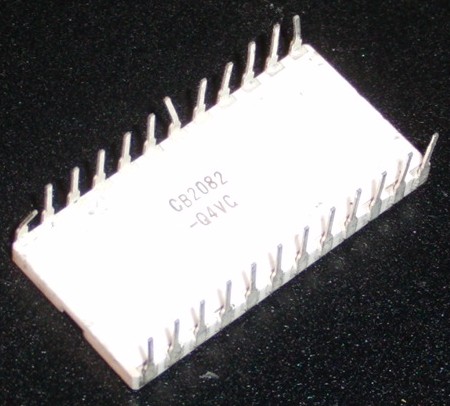

0.3” PPDIP-16 (330 ohm resistor network):

Ceramic DIP (CDIP or CERDIP)

Was popular before epoxy (“plastic”) chips were made commercially viable.

Brown/black

A typical package has two fired ceramic halves with a die in a center cavity held together by glass. Most windowed chips are of this type.

Its unusual to have the ceramic darker on part of the chip but it does make for a nice label! Probably part of the silkscreening process

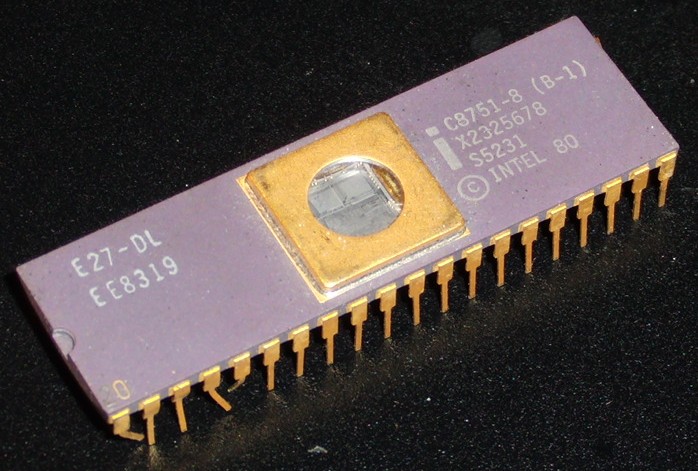

Purple

A typical package is a single co-fired ceramic with a solderable lid. Optional grounding strap. These chips were more common in the 70/80s but still continue to see use in high end and military chips. The last consumer chip I'm aware of was the Pentium 1 which used a dark purple ceramic.

Windowed

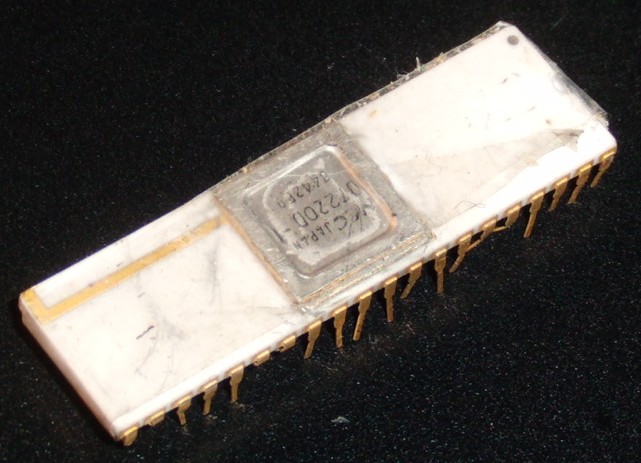

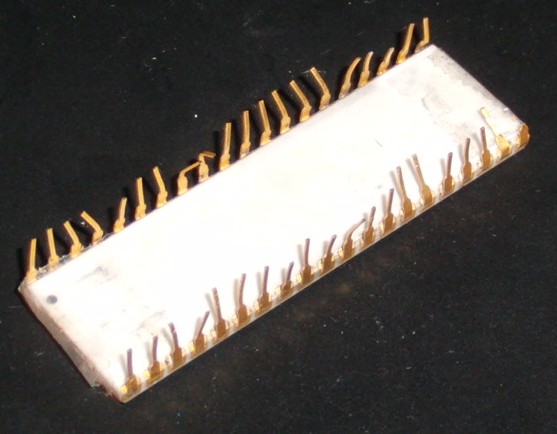

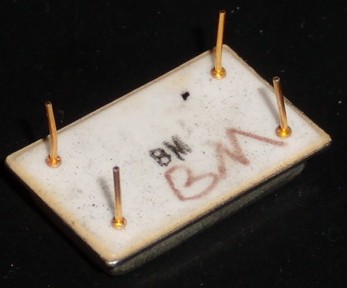

White

A typical package is a single co-fired ceramic with a solderable lid. Optional grounding strap. These chips became uncommon after the 80's in favor of plastic and darker ceramics.

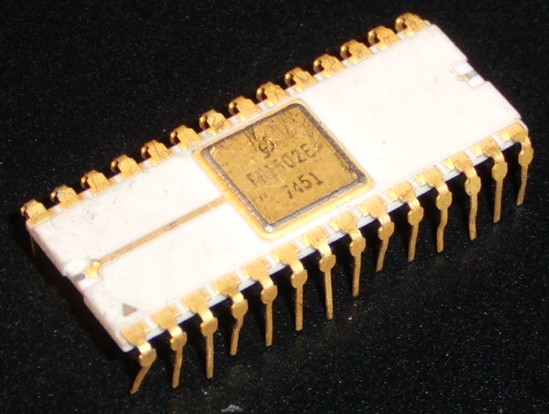

With metal lid and grounding strap:

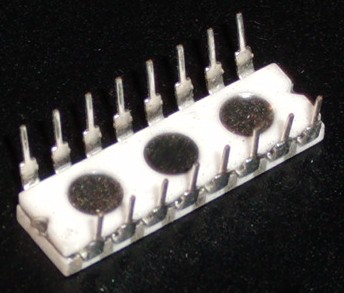

A little unusual co-fired ceramic thick film resistor pack:

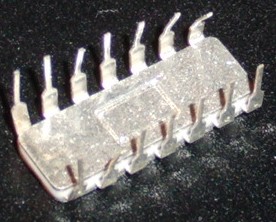

An unusual chip with ceramic sandwhiched by metal plates. I'm unclear if this was co-fired or how the metal was attached?

This chip is a little unusual in that the gold lid appears to have been painted over to make the chip look uniform white! You can see gold where the lid was scratched. 1978 date code

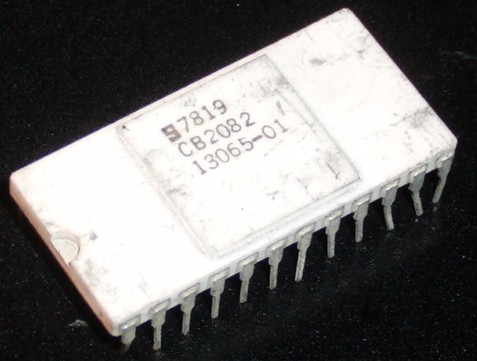

Very early ceramic package (1974 date code):

Windowed

Erasable chips (typically EPROM but sometimes microcontrollers containing EPROM) have a quartz window: