Table of Contents

Ex model: UT100-50 ⇒ 50 mm travel

UT100.25CC.1 ⇒ I think CC.1 refers to the controller they are intended to be used with

The Newport / Micro Controle / Klinger UT100 line of motorized linear stages are reasonably priced, low profile stages. They may be a good choice if you want to build a custom compact microscope stage. Their main drawbacks are that 1), due to their higher than needed precision, they travel slower than desirable, and 2) the motor may be difficult to interface to.

McMaster inventory 2018-08-15

- 1x UE30/50mm: original pr0nscope y stage, probably moderately worn gears

- 1x UE30/50mm: bad shaft coupling

- 1x UE30/50mm: bad shaft coupling (trashed a few years back)

- 2x UE72/50mm: on order

- 2x UE30/50mm: drop in pr0nscope replacement

Bolt pattern

M4 screws

For some reason the counter-bored holes at the base are tapped. I drilled them out to make an M4 bolt slide through

- #14 (0.182“) drill to match existing holes

- Note M4 diameter: 4 mm ⇒ 0.157”

There are feedthroughs that probably allow unbolting a lower stage without unbolting the upper stage (ie remove XY stage from a baseplate)

Looks to be 63 mm bolt spacing

Looks like you need at least 0.15“ clearance from bolt shoulder to top. I observed that 0.155 bolts were getting scraped, 0.150 seemed fine. To be safe, I turned bolt tops down to < 0.13. This was done by holding bolts in a drill while using a Dremel cutting wheel to sand them down.

Motor

| Name | Type | Notes |

|---|---|---|

| UE30 | Variable reluctance stepper | WARNING: most stepper drivers can't (correctly) handle these |

| UE71 | Permanent magnet stepper | Much larger than UE30 |

| UE72 | Permanent magnet stepper | Much larger than UE30 9 mH, 3.3 R, 1.6 A, 5.3 V |

Official controller is CC-1, which can handle UE72 and UE30

UE30

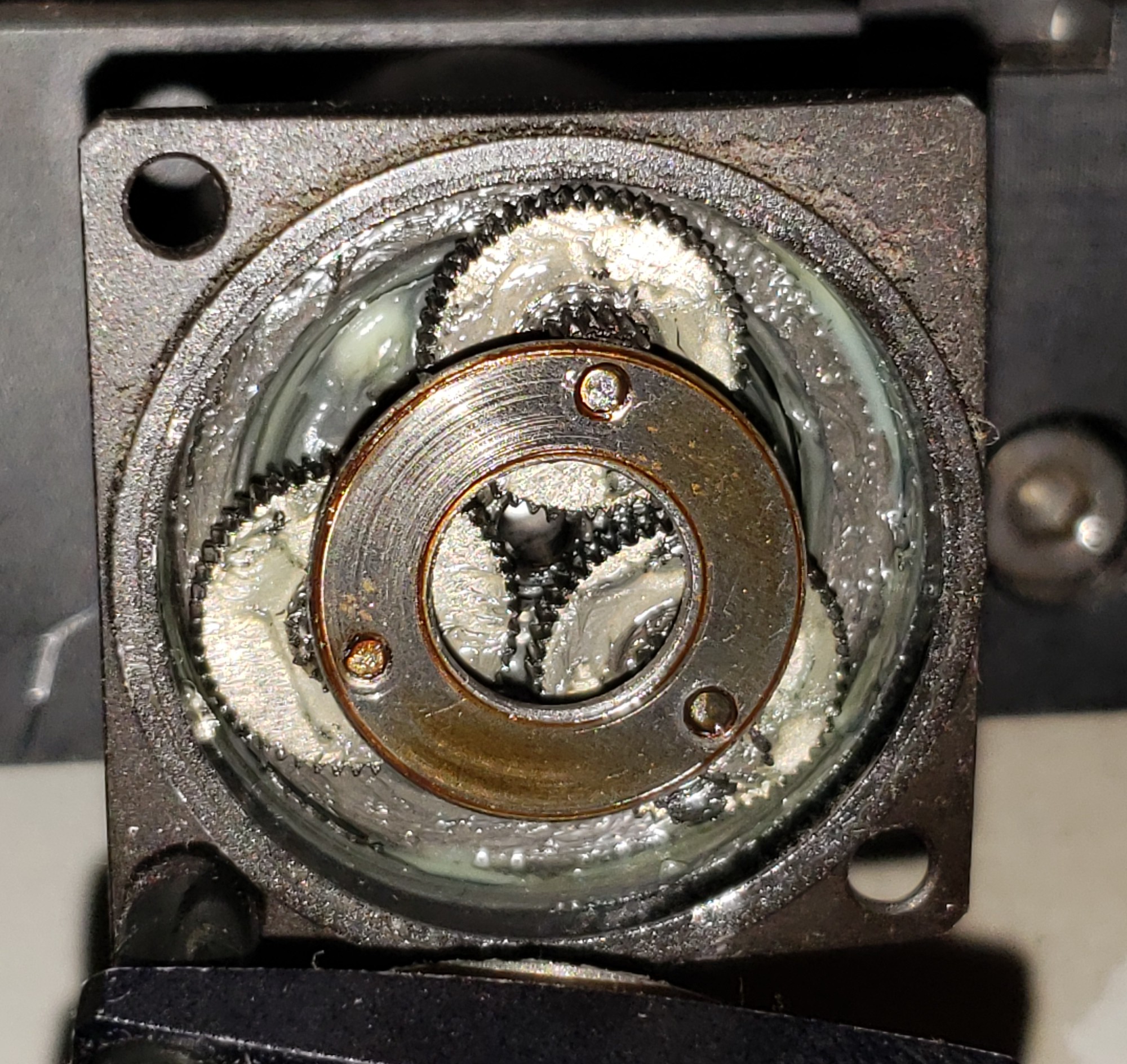

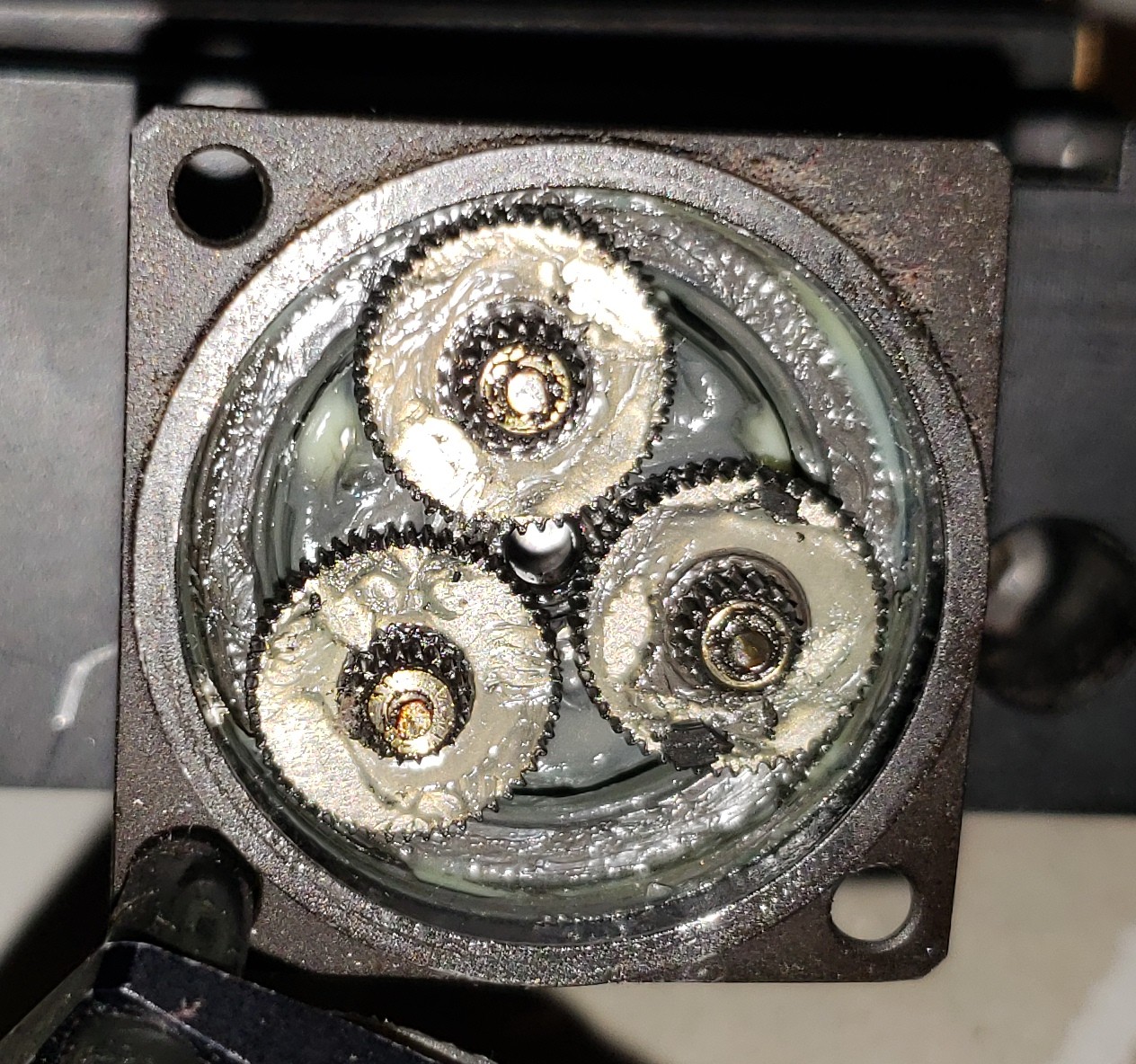

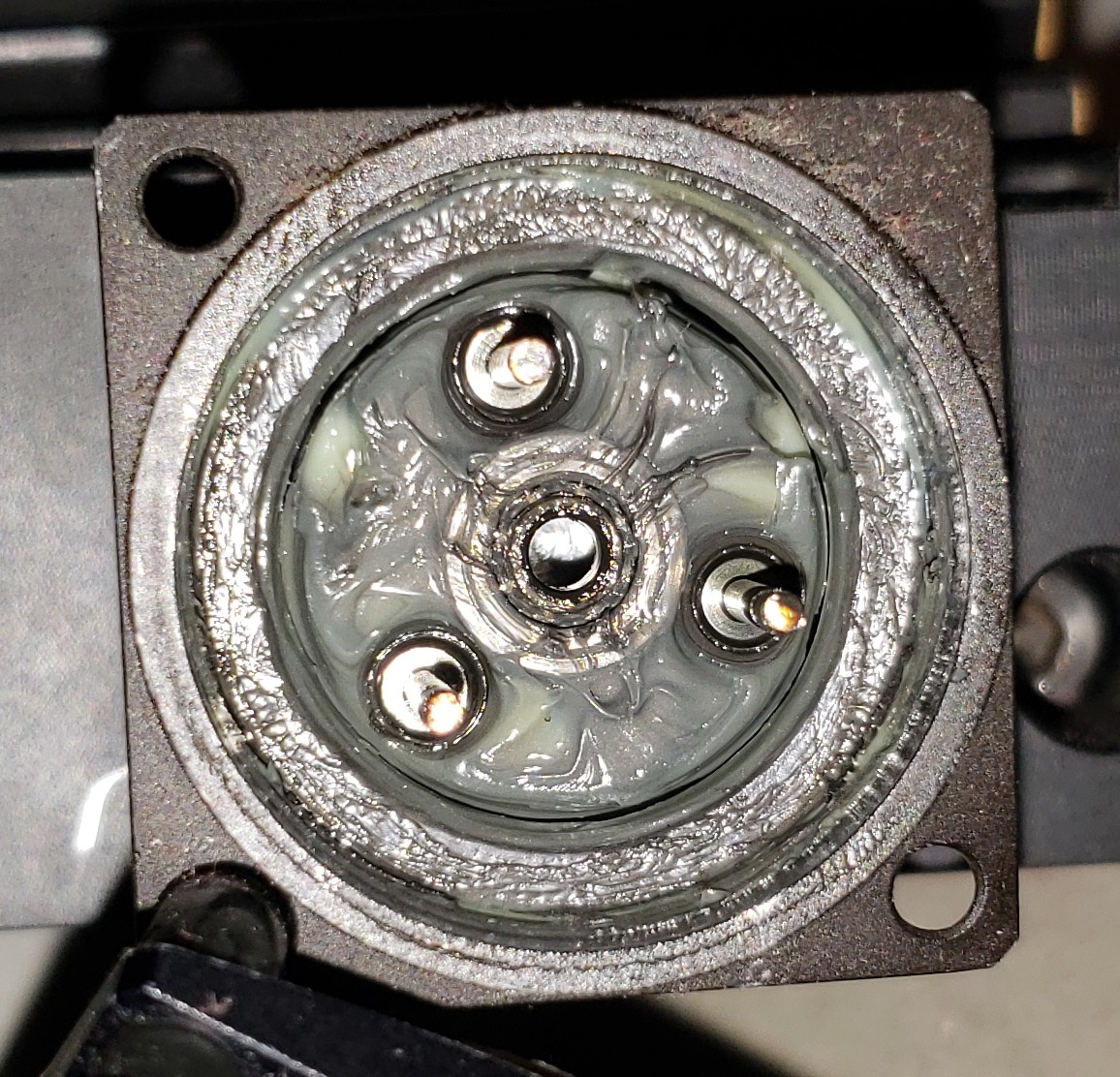

UE30 encoder stepper retrofit

Above: removing encoder. Middle picture shows encoder disk holder, although encoder disk has fallen off

pr0nscope attached an MDrive17 stepper to the encoder by doing the following:

- Used a scrapped MDrive17 for brackets

- Unbolt encoder cover

- Remove encoder

- Attach bracket to UE30

- Think I drilled a few holes?

- Attach standoffs to bracket on the four bolts

- Metric IIRC…M3 maybe

- Mate while inserting shaft coupler between MDrive and UT100

- Screw down standoffs

- Screw down shaft coupler

UE30 PM stepper replacement

I'd like to find a way to directly attach a stepper, such as an MDrive17. Look into this

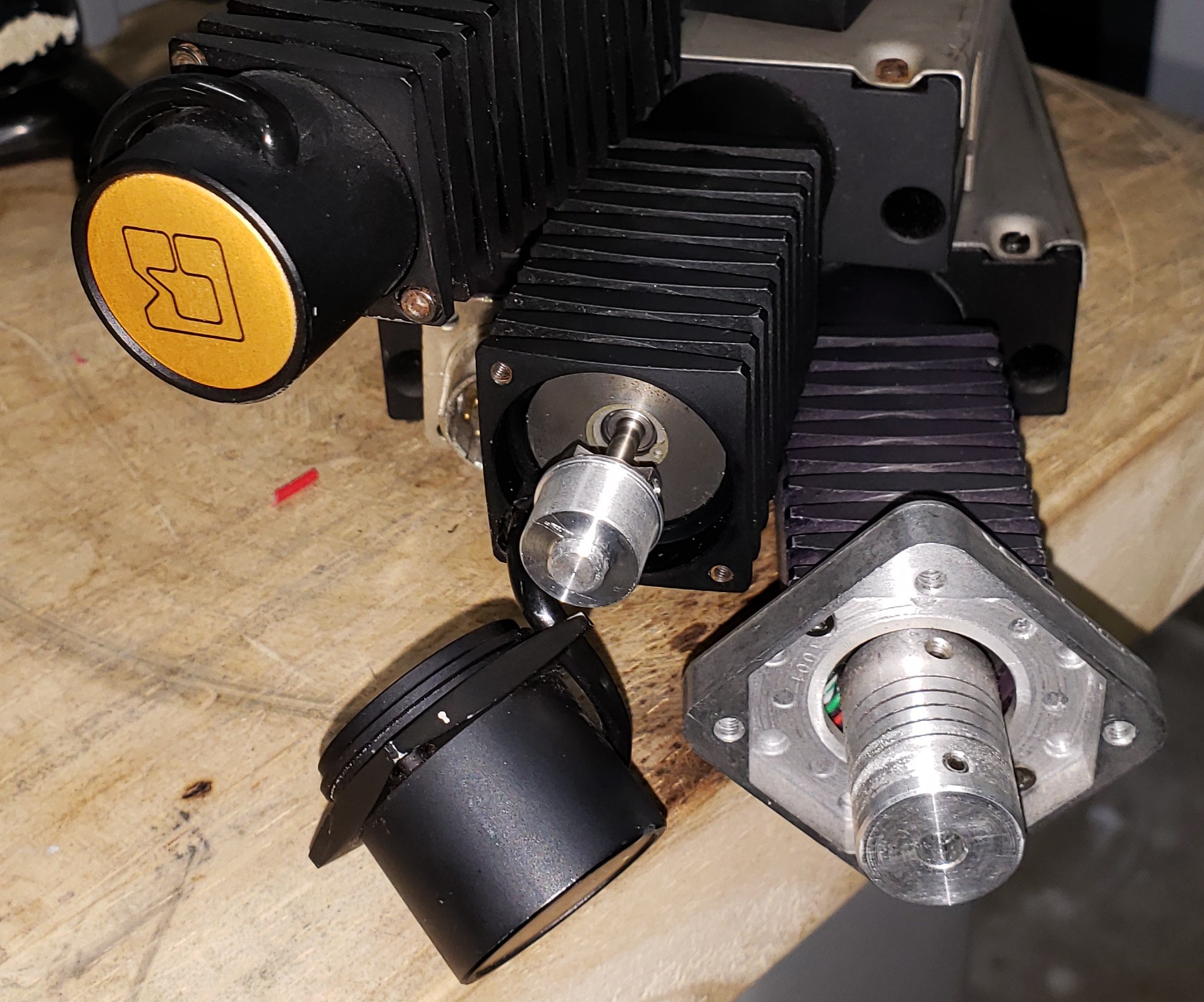

Stage

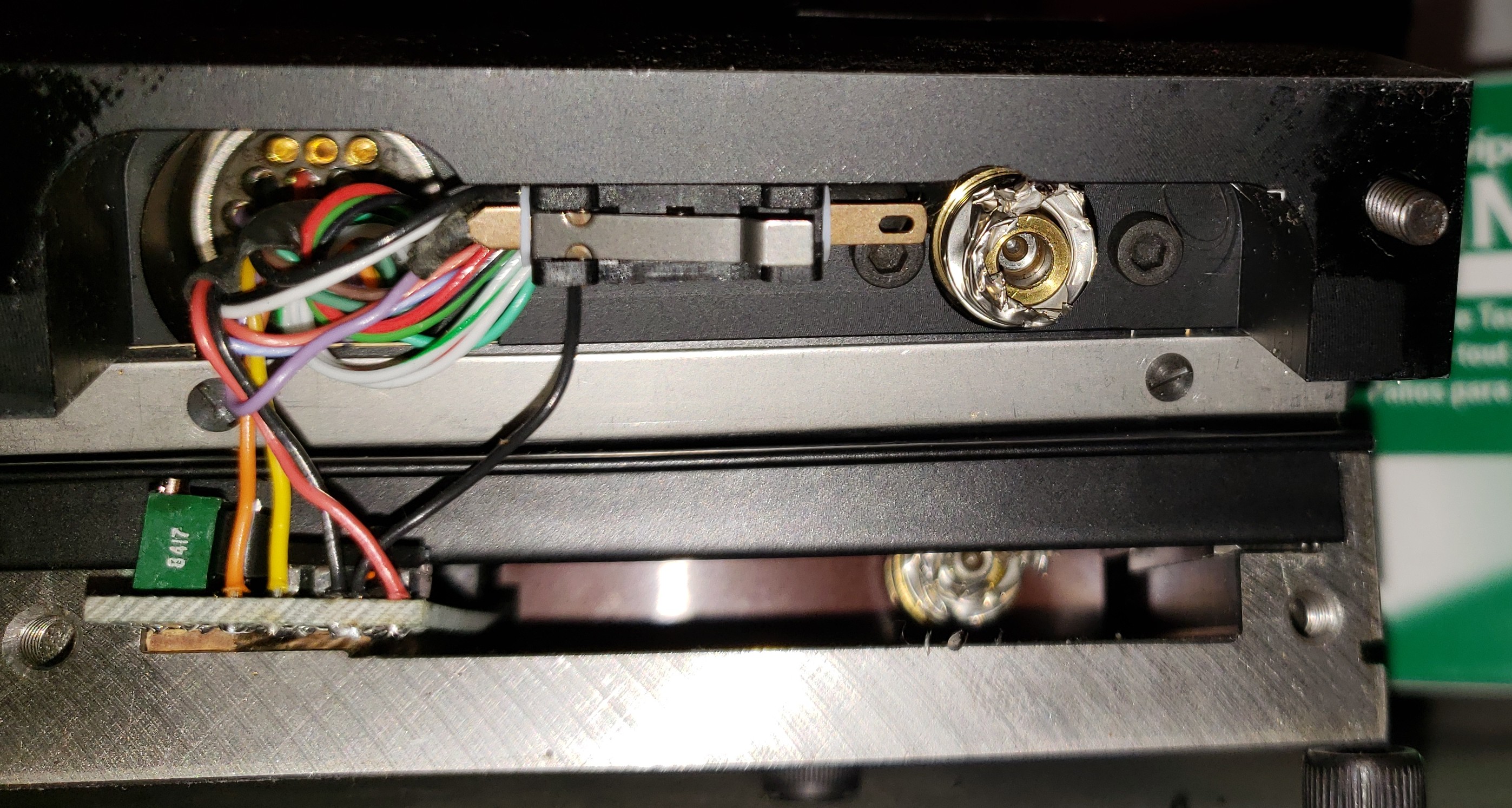

Above: stage open ,showing a sheared coupler

If you crash the axis, an internal shaft coupler may shear (oops). TODO: figure out replacement part number

“bellows style shaft coupler”

https://www.mcmaster.com/#bellows-shaft-couplings/=1e68u37

- High-Misalignment Precision Flexible Shaft Couplings

- Looks like one of these

Connector

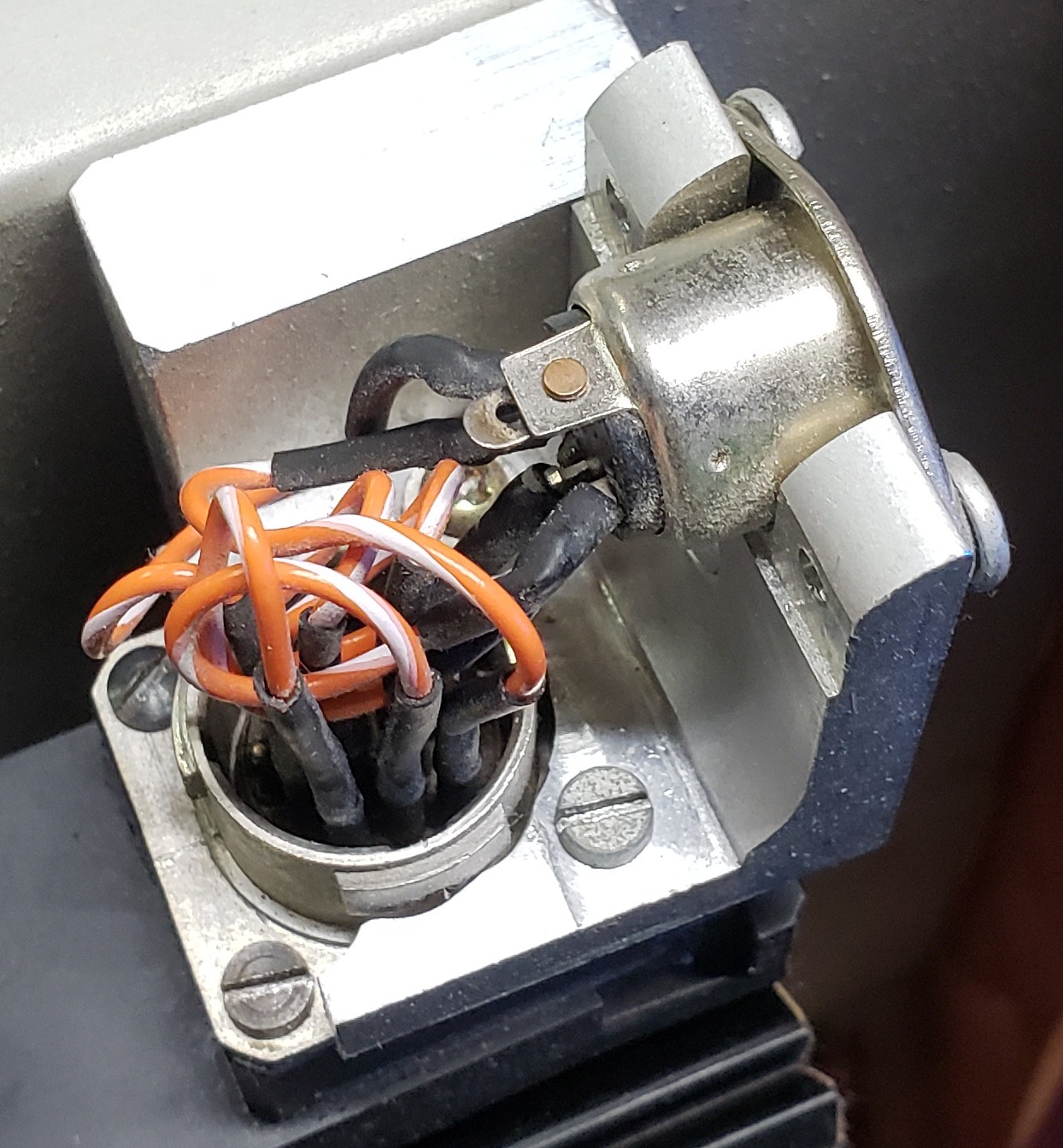

Above: improvised connector

CC-1 manual: “This is a Jaeger 19 pin female connector used to connect stepping motors and Klinger's micropositioning stages to the CC-1 controller.”

2018-08-15:

- Think they are these: https://www.ebay.com/itm/332221856144 (Jaeger 530504-00). I've ordered a lot as a sample and will order more if they fit

- I'm making same cables

- Stepper wire: Molex 1552200235 (16 AWG, multi-conductor, 5 conductor)

Assembly

To remove the shaft coupler: remove the set screw at the bottom of the stage. Then rotate shaft until the second set screw lines up with the just opened hole

mcmaster

| Unit | Travel (mm) | Motor | Notes |

|---|---|---|---|

| 1 | 50 | UE-30PP | pr0nscope X, sheared coupler |

| 2 | 50 | UE-30PP | pr0nscope Y |

| 3 | 50 | UE-30PP | Broke years ago, threw out |

| 4 | 50 | UE-30PP | |

| 5 | 50 | UE-30PP | |

| 6 | 25 | UE71 | |

| 7 | 25 | UE71 |

2018-08-19

- Soldered a connector with pins 1-7, intended to test motor pins 1-6

Unit 4 (UE30-PP variable reluctance) measurements

- A 1-2 L

- 120 Hz: 203 mH

- 1 kHz: 182 mH

- 10 kHz: 122 mH

- 100 kHz: 203 mH

- @ 10 kHz

- A

- 1-2: 122 mH, 24.7 k

- 1-6: 68.0 mH, 13.8 k

- 2-6 66.0 mH, 12.7 k

- B

- 3-4: 127 mH, 26.5 k

- 3-5: 69.7 mH, 11.6 k

- 4-5: 55.5 mH, 21.2 k

Unit 6 (UE71 PM) measurements

- A 1-2 L

- 120 Hz: 46.7 mH

- 1 kHz: 30.0 mH

- 10 kHz: 24.2 mH

- 100 kHz: 45.1 mH

- @ 10 kHz

- A

- 1-2: 24.2 mH, 4.59 k

- 1-6: 6.09 mH, 1.13 k

- 2-6 6.10 mH, 1.14 k

- B

- 3-4: 23.0 mH, 4.59 k

- 3-5: 5.79 mH, 1.13 k

- 4-5: 5.79 mH, 1.12 k

Questions:

- Is it possible to drive above using drivers I have on hand?

- Is it possible to switch parts to fix 50 mm stages with 25 mm parts (shaft coupler)

- Are stepper motors NEMA / can replace with MDrive?

- Does have nice adjustment knob, but unclear if I'd use it

Rorze

11-1 Suitable Motor You can use any HB(hybrid) or PM(permanent magnet) stepping motor with rating of 0.1 to 3A/ph. Select motors with rating of less than supply voltage × 0.7(V).

Highest inductance listed for sample motors is 2.2 mH. If I put the UE71 coils in parallel, 1.5 mH? Seems in the right ballpark anyway

Maybe get some OEM350-RC

UE71

- 103-770-11 motor: https://www.hobbielektronika.hu/forum/getfile.php?id=165680

References

- Forum thread, although maybe not a lot here: https://forum.arduino.cc/index.php?topic=213828.0

- Cross reference table referencing “Klinger Scientific Tables with UE 72 CC Servo Motor”: ftp://ftp.ni.com/support/motion/Manuals/nuDrive.pdf

- Goniometer product brief: https://www.equipx.net/uploads/Klinger/KlingerBG120goniometer.pdf