Table of Contents

There are two common types of epoxy packages: thermoset epoxy used for PDIPs and the like, and epoxy resins used for PGAs. The former are typically dark brown or black and mixed with glass beads, while the latter are typically green, yellow, or brown with layered fiberglass. [Thermoplastics for Packaging 1]

Glass transition temperature

Unlike plastics, once an epoxy is set it cannot be melted. However, there exists a temperature at which an epoxy is considerably weakened. Literature may call this “Tg”. This can be exploited to thermomechanically decap packages without chemicals.

Transitions for various epoxies [Smithers Rapra 18, 19]:

| Epoxy resin | Curing agent | Tg (C) |

| DGEBA | DDM | 190 |

| DGEBA | DDS | 189 |

| DGEBA | DETDA | 195-217 |

| DGEBA | Jeffamine-130 | 65 |

| DGEBA | Jeffamine-800 | 0 |

| DGEBA | TETA | 139 |

| TGAP | DETDA | 260 |

| TGDDM | DETDA | 230 |

With:

- DDM: 4,4 ́ Diaminodiphenyl methane

- DDS: 4,4 ́ Diaminodiphenyl sulfone

- DETDA: Diethyl toluene diamine, CAS 68479-98-1

- DGEBA: Diglycidyl ether of bisphenol A, CAS 1675-54-3

- TETA: Triethylene tetramine Dioctyl phthalate Diglycidylether of 1,4 butane, CAS 112-24-3

- TGAP: Triglycidyl p-amino phenol, CAS 5026-74-4

- TGDDM: Tetraglycidylether of 4,4′ diaminodiphenyl methane

Thermoset epoxy

An epoxy molding compound (EMC) based package is thermoset (cured) by transferring it hot into a mold and then quickly (a few minutes) set by keeping at an elevated temperature. I think its for this reason that they are often referred to as “mold compound”. Also these are often called “plastic” packages but as far as I can tell this is a misnomer (example: a plastic dual inline package (PDIP) is really epoxy/glass). [Thermoplastics for Packaging 77] mentions that some early packages in the 70's used thermoplastics. More than likely the term was carried over even though it no longer strictly applies (likes MOSFETs with poly gates…).

XXX: Dynaloy decap is aginast tetramine, Tg also leans towards TETA

Manufacturing process

First a die is attached to a leadframe with some polymer adhesive. (XXX: what holds the leadframe together?) This is heated for quick cure and then bond wires are attached. The chip is now ready for encapsulation and are placed in rows in a heated transfer mold. Chips are seperated by a “series of runners and gates. EMC in the form of solid pre-heated preform (called a puck), is moved into the chamber and heated to melting. An auxiliary ram then pushes the liquefied material through the runner and gates into the cavities, completing the transfer process and encapsulating the chip and lead frame. Post heating may be required to fully-polymerize the epoxy.” [Thermoplastics for Packaging 4]

Setup time is around 30 seconds. For example [PCN0702]:

| Epoxy | Temp (C) | Gel time (s) |

|---|---|---|

| EME6300 | 175 | 24-41 |

| Sumitomo G700 | 175 | 30 seconds |

| DMC 2000HG | 175 | 26 |

Composition

Many thermoset epoxies contain bromine for flame retardation [Thermoplastics for Packaging 3].

The following have been observed:

- Epoxy resin

- The specific contents are almost always omitted

- Seen “Brominated epoxy resin”

- Phenol resin

- The specific contents are almost always omitted, sometimes see “Phenol novolac”

- Fused silica

- Antimony trioxide

- Carbon black

- Crystalline silica

- Metal hydroxide

- Specific contents always omitted

Vendor epoxies

This is temporary staging, will eventually be moved to the Archive. NOTE: these results are biased around MP8000CH4 since I used it to find the others

- 7304LCF [Amkor moisture]

- Hitachi CEL9220HF10 [Hana BOM, PCN1-110704]

- Hitachi CEL9220HF13H [Hana BOM]

- DongJin DMC 2000HG [PCN0702]

- Hysol MG97-8006A [Hana BOM]

- Optically clear…might not be transfer molded

- Nitto MP8000AN [Hana BOM]

- Nitto MP8000CH [Hana BOM]

- Nitto MP8000CH4 [Mindspeed product change note, Amkor moisture, Hana BOM, PCN0702]

- Nitto MP8000CH4-A2 [Cypress S32456]

- Shinetsu KMC3580P14F [Hana BOM, ON PCN 16118]

- Sumitomo 6650E [Mindspeed product change note]

- Sumitomo 7320CR [Mindspeed product change note]

- Sumitomo 7351LS [Mindspeed product change note]

- Sumitomo EME-6600CR [Hana BOM]

- Sumitomo EME-6300H [PCN0702]

- Sumitomo EME-6300HJ [Amkor moisture, PCN0702]

- Sumitomo EME-6300HR [Hana BOM]

- Sumitomo EME-6710S [Hana BOM]

- Sumitomo EME-G700L [Mindspeed product change note]

- Sumitomo G600 [Hana BOM, PCN0702]

- Sumitomo G700M [PCN0702]

Sample Tg [PCN0702]:

| Epoxy | Tg (C) |

|---|---|

| Sumitomo EME6300 | 165 |

| Sumitomo G700 | 130 |

| DMC 2000HG | 140 |

| Sumitomo G600 | 135 |

| Nitto MP8000CH4 | 150 |

[Hitachi EMCs] lists more Tg in about the same range

[SI chapter 3] shows “BT Resin Glass Epoxy” as the substrate for “OMPAC Ball Grid Array From Motorola”

MP-8000CH4-EN

| Name | CAS | Mass % |

|---|---|---|

| Solid epoxy resin | N/A | 2-20 |

| Phenol resin | N/A | 2-20 |

| Fused silica | 60-95 | 60676-86-0 |

| Antimony Trioxide | 1309-64-4 | 1.2 |

| Carbon Black | 1333-86-4 | < 1 |

| Crystalline Silica | 14808-60-7 | < 5 |

Hitachi CEL9220HF13H

| Name | CAS | Mass % |

|---|---|---|

| Epoxy Resin-1 | N/A | 2-5 |

| Epoxy Resin-2 | N/A | 1-3 |

| Phenol resin | N/A | 2-5 |

| Silica | 60676-86-0 | 77-92 |

| Carbon black | 1333-86-4 | 0.2 |

| Metal hydroxide | N/A | 1-10 |

| Other | N/A | ⇐ 0.5 |

Sumikon EME-6600CS

[Sumikon EME-6600CS]

| Name | CAS | Mass % |

|---|---|---|

| Fused silica | 60676-86-0 | 70-90 |

| Epoxy resin | N/A | 8-12 |

| Phenol novolac | 9003-35-4 | 4-7 |

| Antimony trioxide | 1309-64-4 | 1-3 |

| Brominated epoxy resin | 68541-56-0 | 1.6-3.5 |

| Carbon black | 1333-86-4 | 0.1-0.5 |

Hitachi CEL-9200

[Hitachi CEL-9200]

| Name | CAS | Mass % |

|---|---|---|

| Epoxy resin | 85954-11-6 | 4-6 |

| Phenol resin | 26834-02-6 | 4-6 |

| Brominated epoxy resin | 68541-56-0 | 1 |

| Antimony trioxide | 1309-64-4 | 0.5 |

| Silica | 60676-86-0 | 87-90 |

| Others | N/A | 1 |

Sumikon EME-6710SJ

| Name | CAS | Mass % |

|---|---|---|

| Silica fused | 60676-86-0 | 60-90 |

| Epoxy, cresol novolac | 29690-82-2 | 5-15 |

| Phenol novolac | 9003-35-4 | 3-10 |

| Antimony trioxide | 1309-64-4 | 1-5 |

| Brominated epoxy resin | 68541-56-0 | 1-3 |

| Carbon black | 1333-86-4 | 0.1-0.5 |

Epoxy is Poly[(o-cresyl glycidyl ether)-co-formaldehyde]

Epoxy resin

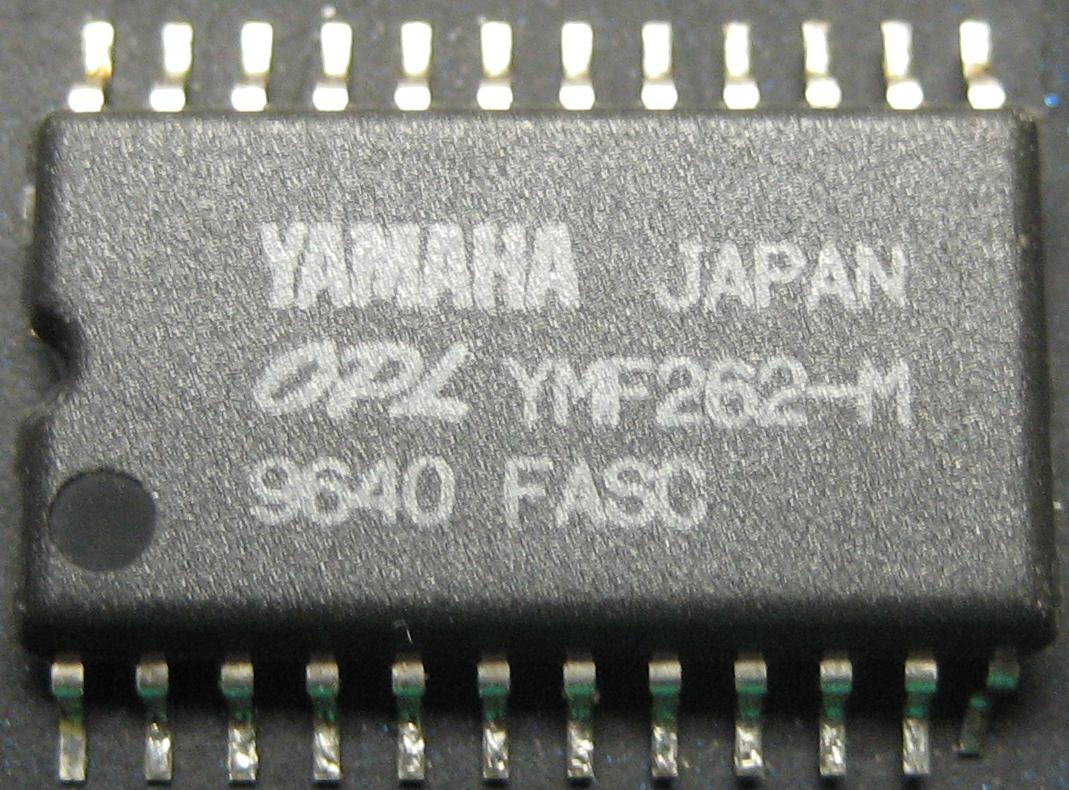

Used to make packages very similar to FR4. Occasionally used to make certain optical packages, although typically these are plastic. Above: typical epoxy resin package.

BT resin seems common. TODO: others

Misc

Packages commonly use epoxy or silicone. “The last of the three basic encapsulants is polyimide. Polyimides are used less often in IC packaging as an encapsulant. They are fairly common in die-attach adhesive formulations.” One of the charts also mentions BCB (?). [Materials and methods for IC package assembly]

References

- Epoxy Resins - Smithers Rapra: http://info.smithersrapra.com/downloads/chapters/Thermoset%20Resins.pdf

- This is a very nice read beyond just IC RE. Has some neat stuff like how to determine amount of curing compound needed

- TIME to CONSIDER THERMOPLASTIC MATERIALS for ELECTRONIC PACKAGING (Thermoplastics for Packaging): http://www.et-trends.com/files/Thermoplastics_for_Packaging.pdf

- Materials and methods for IC package assembly: http://www.electroiq.com/articles/ap/print/volume-14/issue-8/features/the-back-end-process/materials-and-methods-for-ic-package-assemblies.html

- Mindspeed product change note: http://www.mindspeed.com/assets/001/28XXX-PCN-002-A.pdf

- Cypress S32456: http://smartdata.usbid.com/datasheets/usbid/2001/2001-q1/002605.pdf

- Amkor moisture: http://klabs.org/richcontent/Reliability/amkor_moisture.pdf

- Hana BOM: http://www.hanagroup.com/pkg_ayt/bom.pdf

- Altera PROCESS CHANGE NOTIFICATION PCN0702 UPDATE: http://www.altera.com/literature/pcn/pcn0702.pdf

- This has a lot of good info including material properties

- MP-8000CH4-EN MSDS: http://www.fujitsu-nt.com/cn/pdf/NITTO-MP8000CH4-EN-MSDS.pdf

- ENERGY micro PCN No: PCN1-110704

- ON PCN 16118: http://www.onsemi.com/pub/docs/pcn/FPCN16118.pdf

- SI chapter 3: http://smithsonianchips.si.edu/ice/cd/BT/SECTION3.PDF

Things to look into:

- Characterization of Integrated Circuit Packaging Materials