Table of Contents

There are two primary ways to seal ceramic packages:

- Glass frit seal

- Metal solder seal

- Includes both conventional and co-fired ceramics

See also: Background

Metal lid

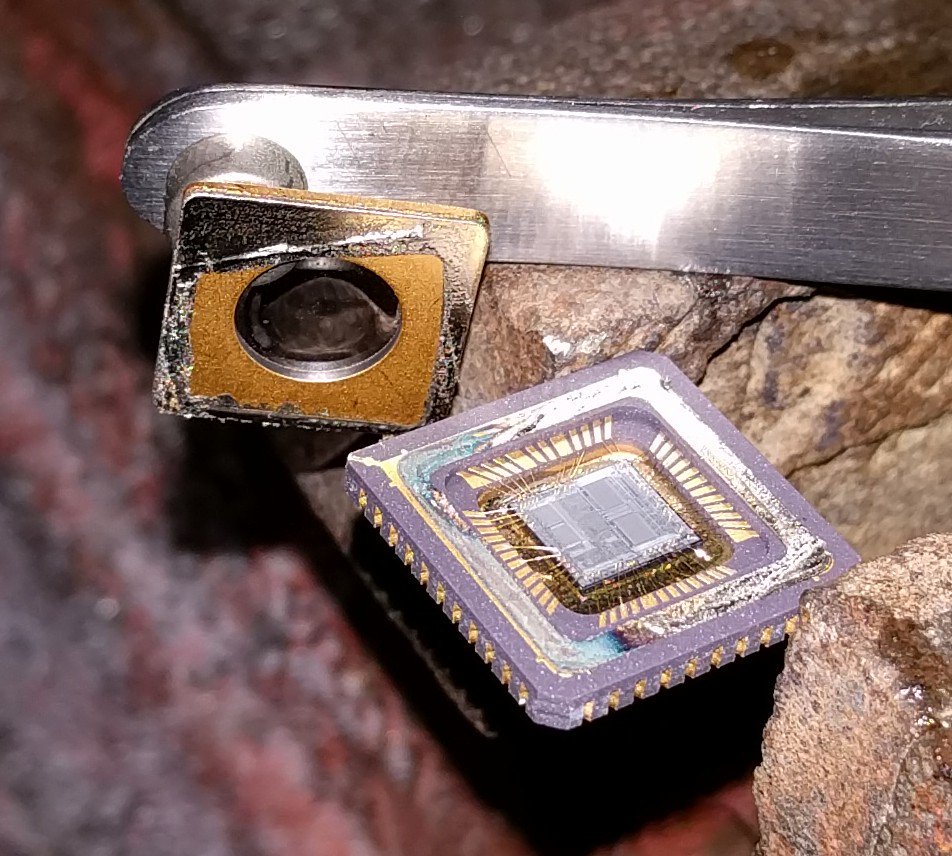

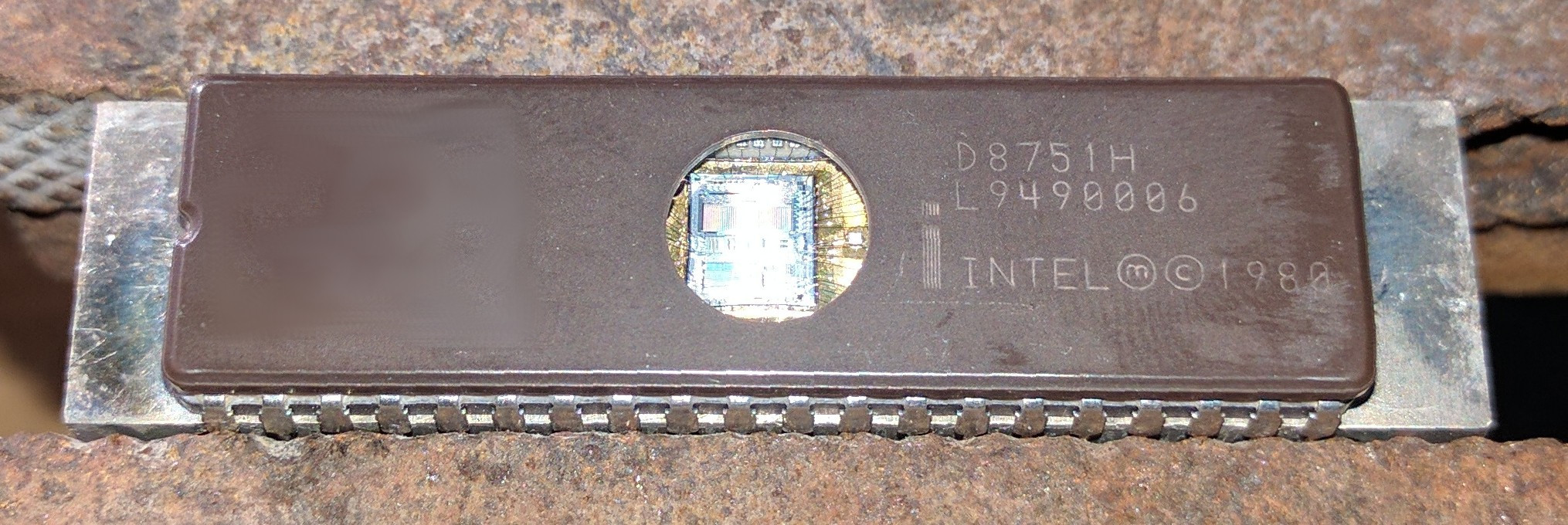

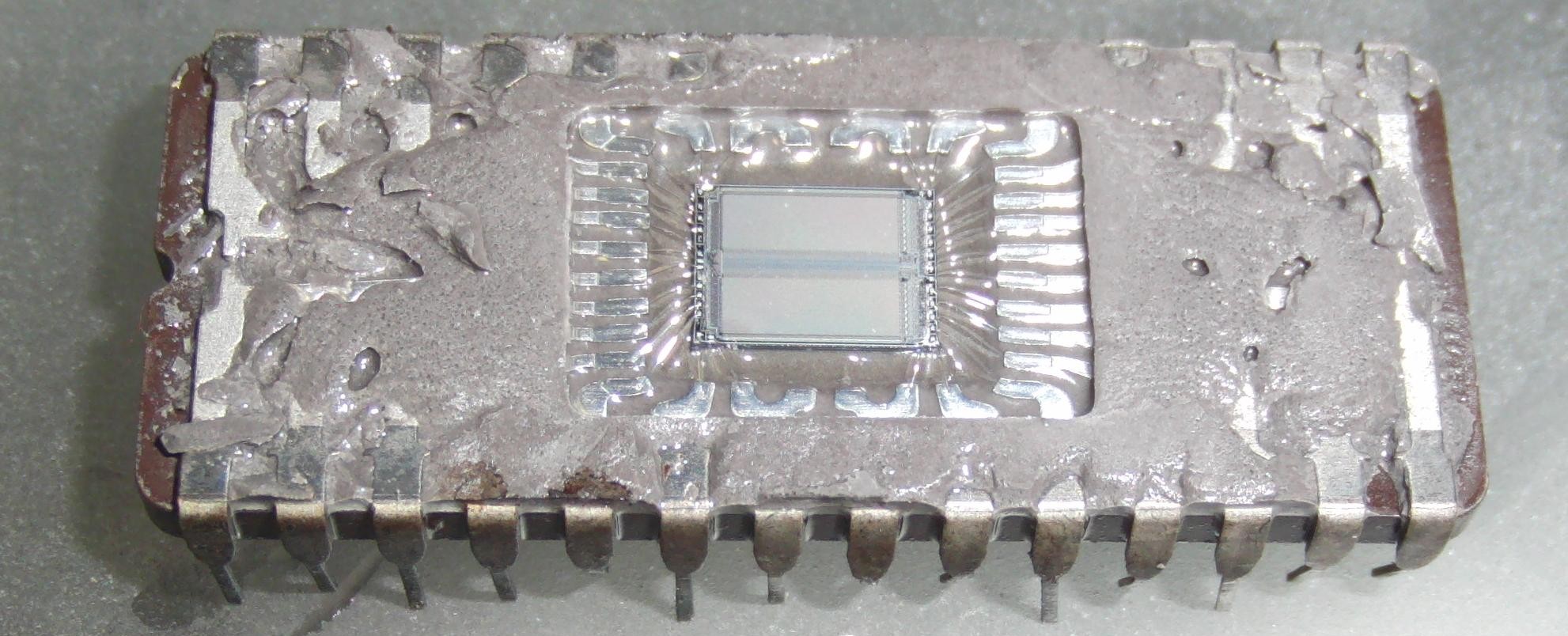

Above: 8751 decapped using a torch + magnet

See also: Metal

For metal lid ceramic

Gently heat package. If possible, attach a heat spreader to the bottom. If possible, avoid clamping the ceramic directly or at least make it springy (to avoid thermal expansion stress)

When the top lid seal melts, use a magnet to pull it off. This avoids issues like a knife slicing bonds or sliding over and dropping metal.

Glass frit

2020-10-21

- General consensus may be that heating to below melting point (softens but doesn't liquefy glass) followed by shearing may be the best approach for most

- Mind heat and cool cycles to avoid thermal shock

JM 2016-11 advice:

- Use “Top Heat (gentle)” for safest result

- Use “Top Heat (quick)” for less safe but cleaner result

- Milling theoretically results in stronger package, but I've had lower success rate and ultimately makes die access harder

Top heat

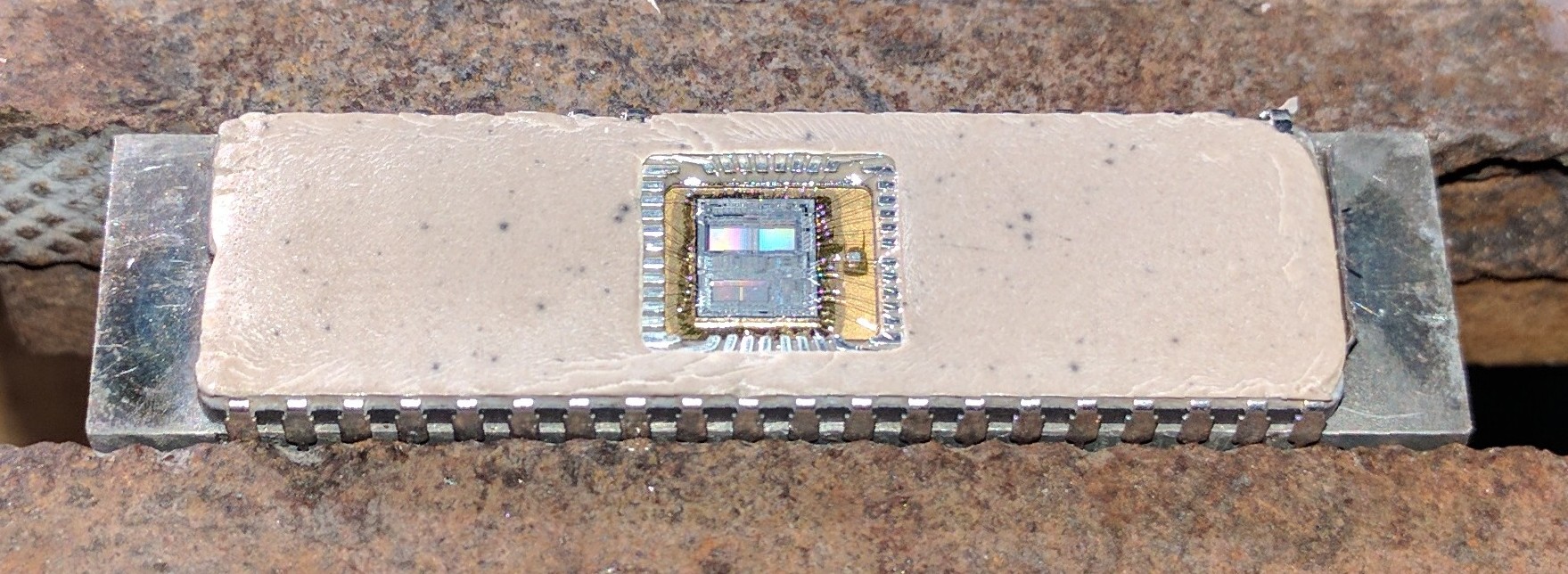

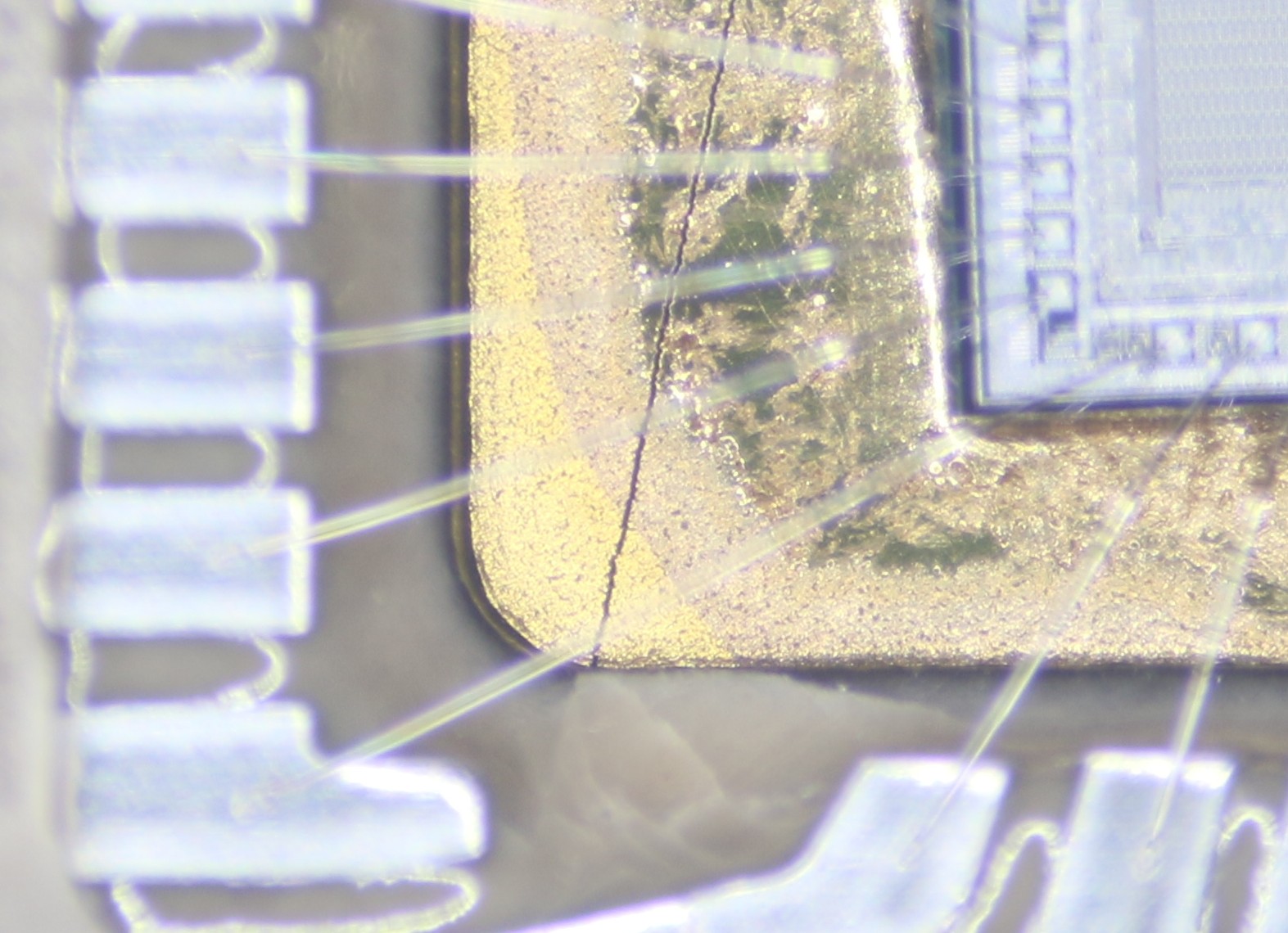

Above: typical gentle result

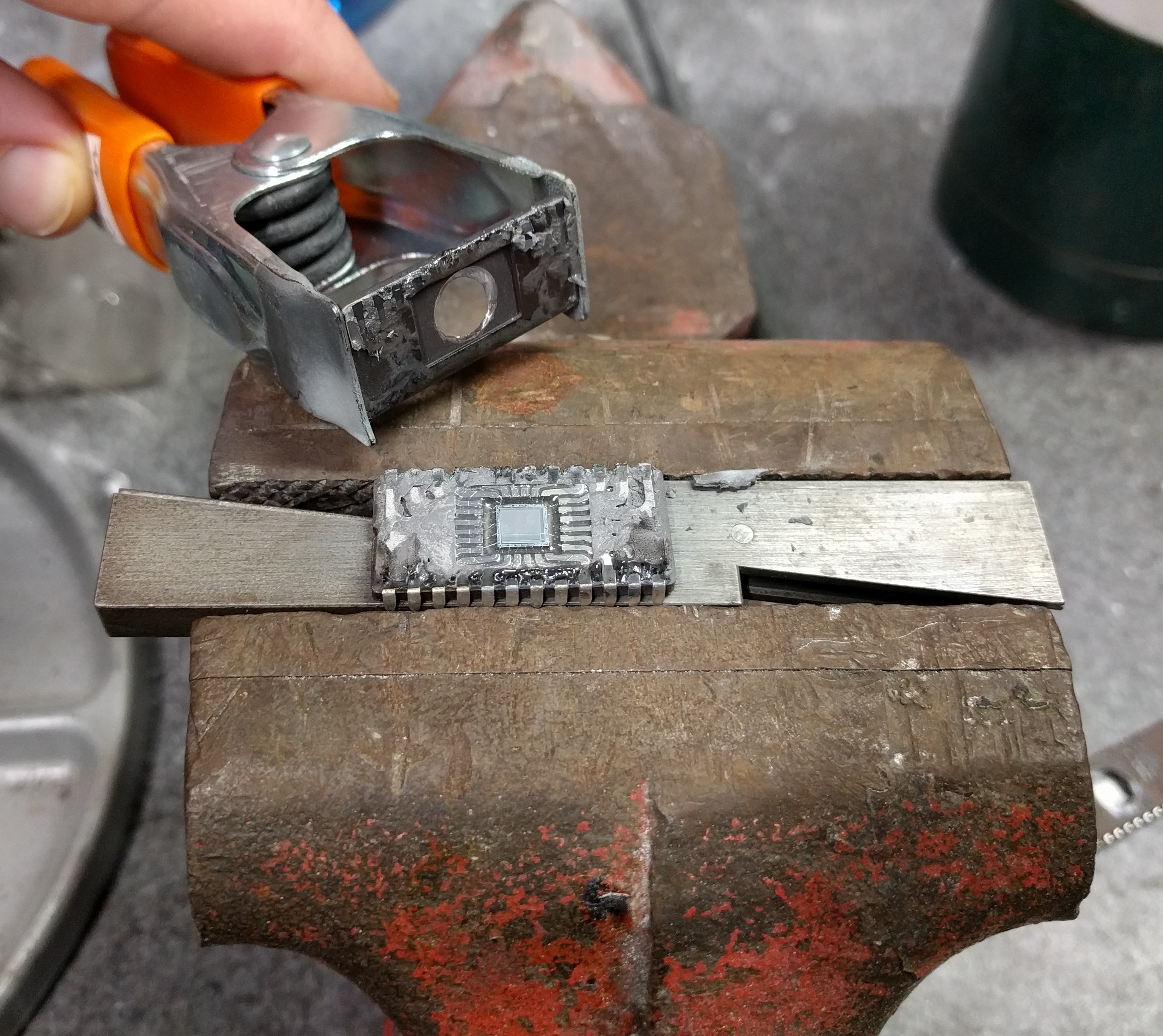

Above: using a spring clamp to better hold the ceramic. Preliminary results indicate this allows much better control than using pliers to hold the top. Possibly could crack and collapse though

Gentle procedure:

- Place chip into heat spreader block

- Place chip + spreader into vice

- Torch heat spreader

- DIP28: ~10 seconds

- DIP40: ~20 seconds

- Or: I started pre-heating using heatgun instead. IIRC 500F was a good point. Higher and it didn't give good enough thermal gradient

- Begin torching top of chip

- Use the side of the flame, not the tip, for gentler and more even heating

- Every 5-10 seconds try to pry lid up. If it is starting to budge, immediately do the next few steps

- Stop torching

- Gently pull lid up and over chip, hinging on the far side

- Separate lid from package

Above: typical quick result

Quick procedure:

- Place chip into heat spreader block

- Place chip + spreader into vice

- Begin torching top of chip

- Side or tip of flame better?

- Every 5-10 seconds try to pry lid up. If it is starting to budge, immediately do the next few steps

- Listen for a small popping noise. This usually indicates the lid has sheared from the frit and can be easily removed, possibly with slightly more heat

- If its not the lid, the package has probably cracked

- Stop torching

- Gently pull lid up and over chip, hinging on the far side

- Separate lid from package

General notes:

- Wave torch back and forth to keep heat even

: torch model I use

- DO NOT torch while lid is lifting. Will quickly destroy bond wires

- Clamp pins against heat spreader, not ceramic body

- Ceramic body needs room to expand. Clamping it may result in fracture

- Heat spreader can be aluminum or steel

- Steel won't be melted by propane torch

- Aluminum can melt if abused, but will conduct heat better

- If the package cracks, finish procedure and then assess damage. The spreader should keep package integrity until assessment is done. If the die cracks, the chip is probably a loss

Above: typical crack due to not pre-heating bottom

Bandsaw

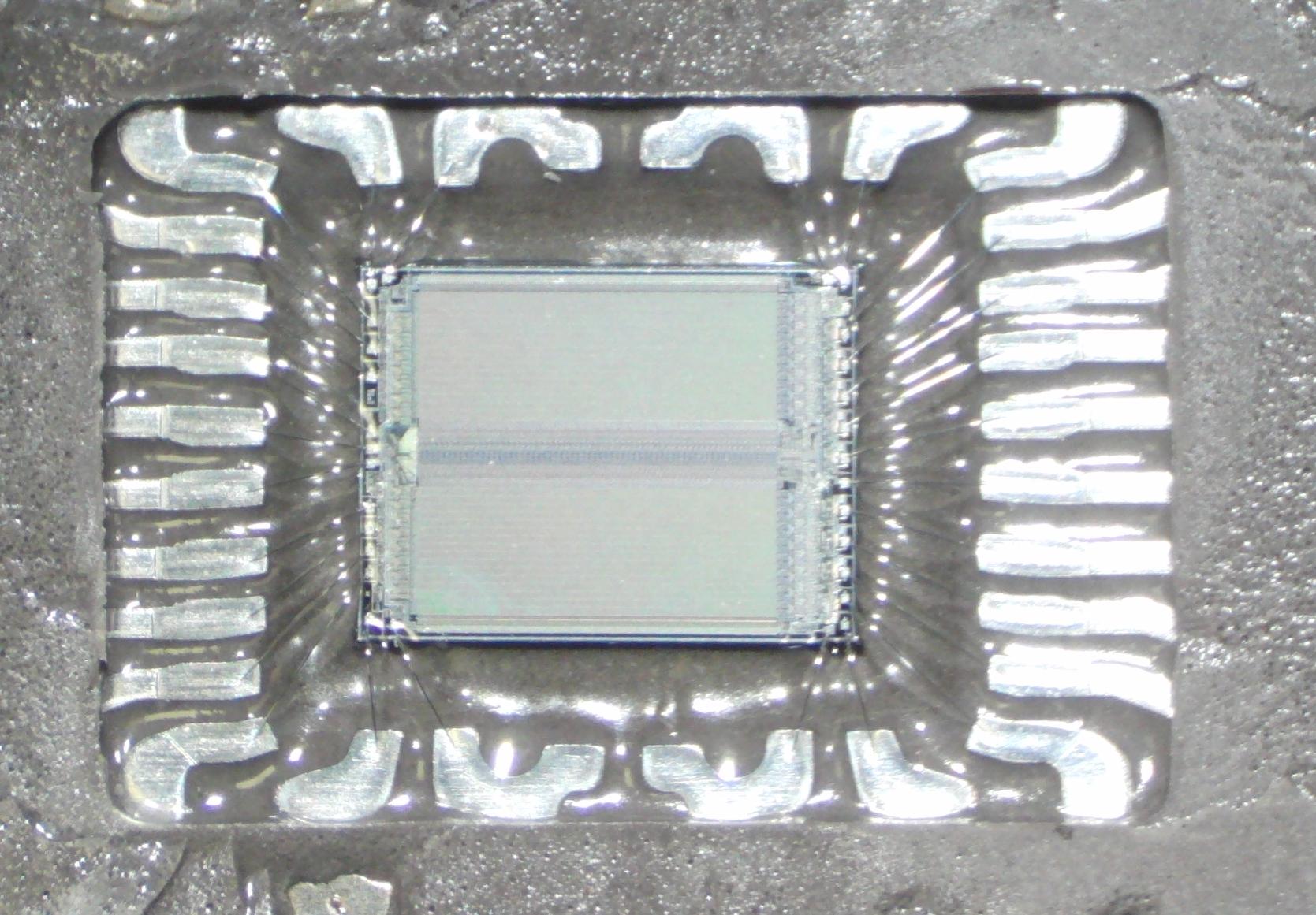

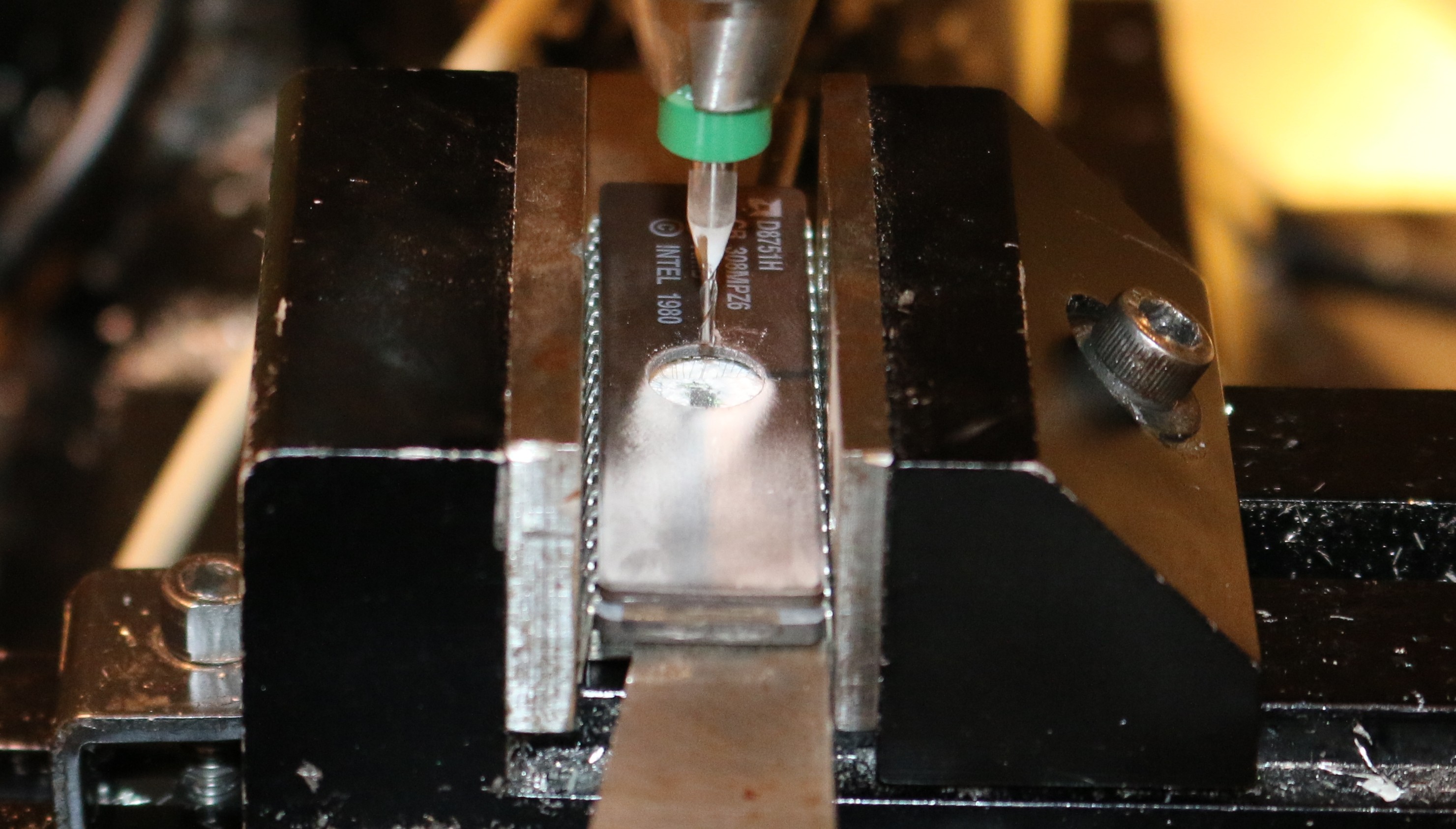

Above: fixturing for cutting. Sample held in DIP 40 ZIF. Use cross slide to stablize.

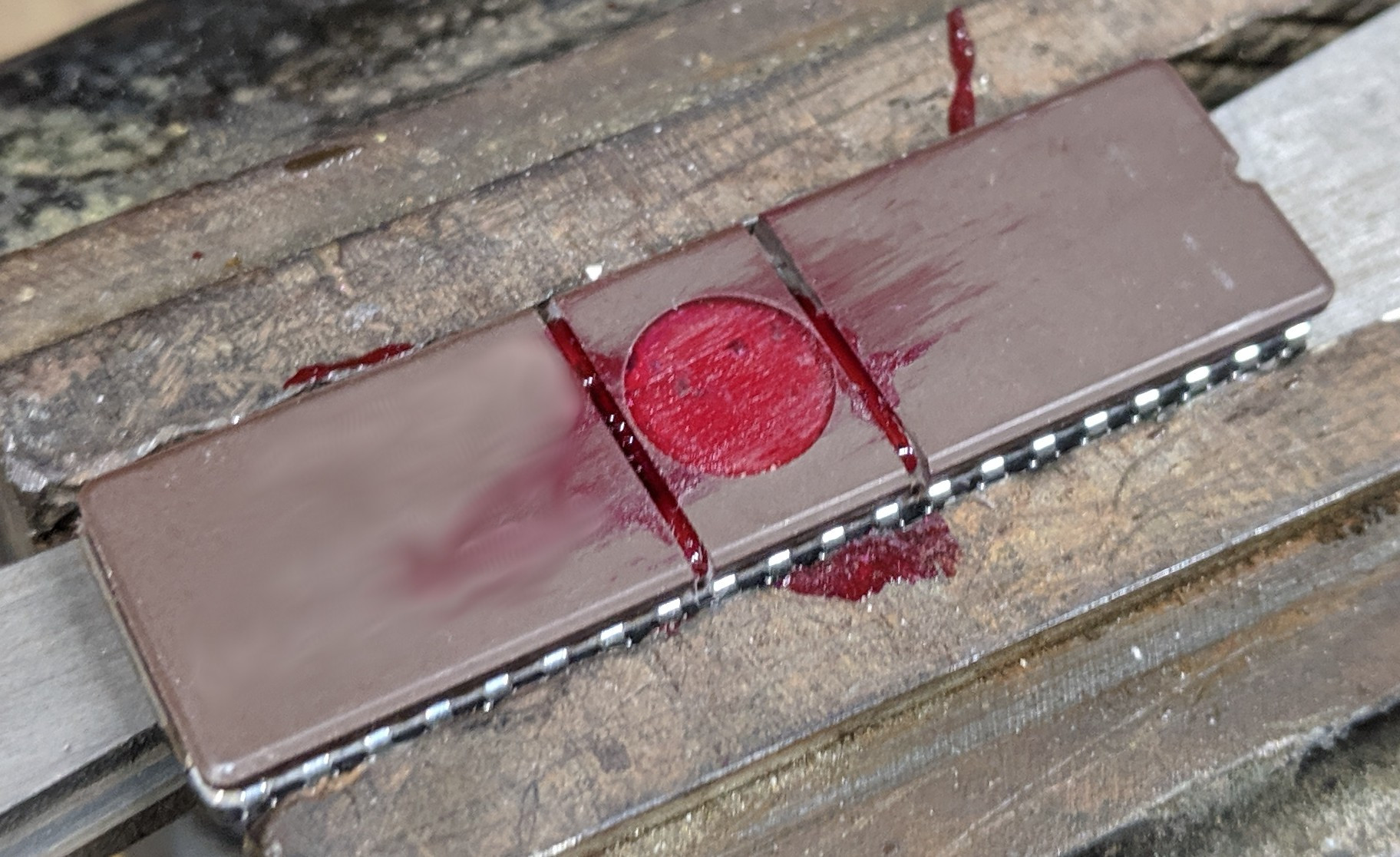

Above: cuts on far sides of cavity. They are above wires but not the die

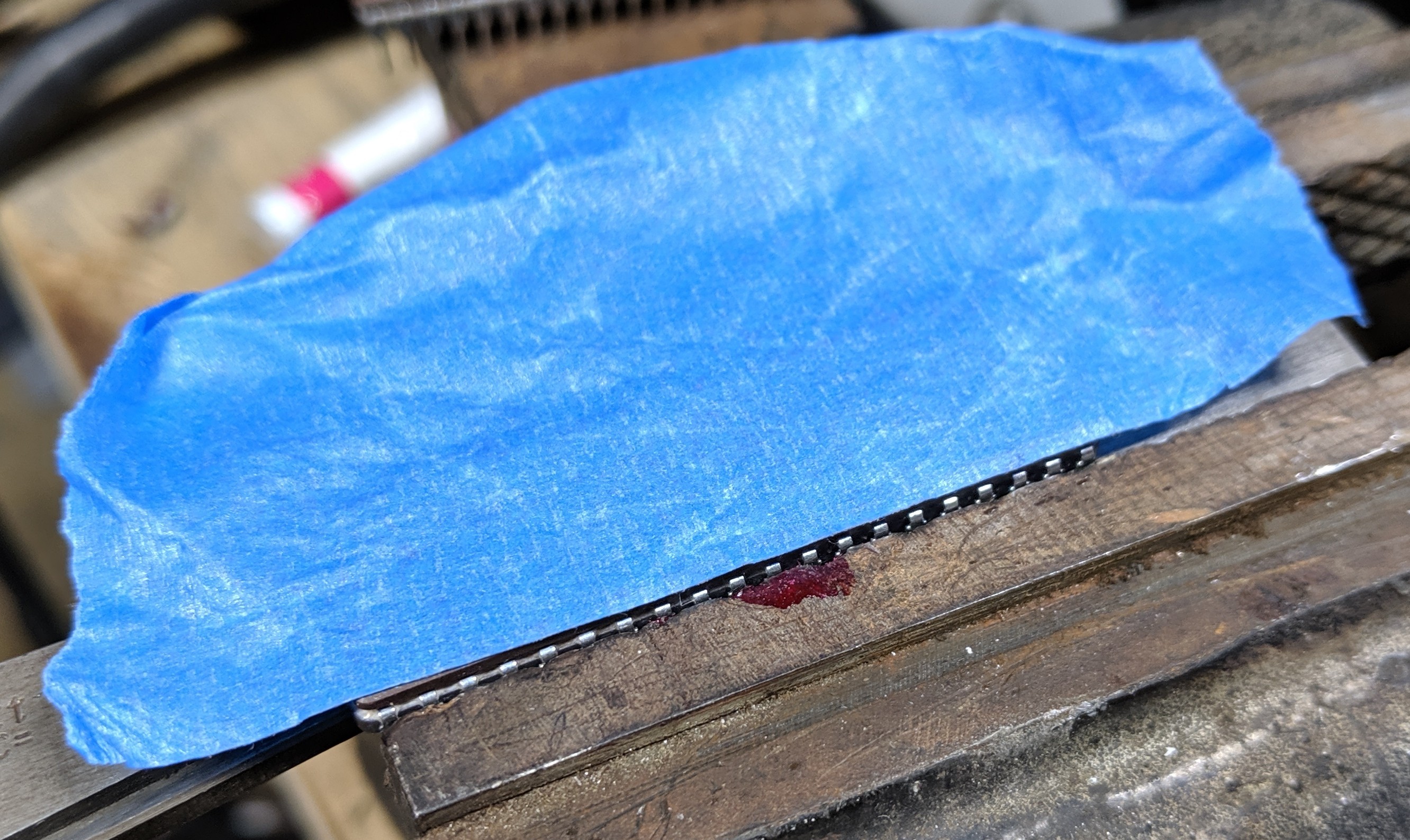

Above: tape placed to keep lid in place as its sheered off. Excessive movement may damage bond wires. Tape also helps retain large pieces if it fractures.

Above: lid peeled off after sheering

DB-100 diamond bandsaw

2019-12-16 procedure for large ceramic packages:

- Place chip in DIP-40 socket to help steady during cutting

- Saw a slit on both sides of the cavity

- As far as possible, usually about 0.1“ after the quartz window

- Saw just into the glass frit

- WARNING: failing to completely separate ceramic can lead to unpredictable breakage

- Should be roughly above where the bond wires attach but not above the die

- Small debris in the cavity is normal and shouldn't hurt the die

- Pins make good guides. I usually saw between two

- Fill with nail polish to help protect the die against debris

- Use a small pipette to pump it into the cavity from one side

- Should push out any water from sawing

- Alternatively, for small packages it may make sense to simply grind (see below)

- Place in vice with top cavity just above jaws

- Place tape over top of package

- Gently tap side of lid with chisel to sheer it

- Peel away tape and lid together

- Wash nail polish away with acetone

- See UV masking page for more info

Grinding:

- Grinding was used more initially, but can be slower (especially for large packages) and may have increased change to damage die

- Alternate side of blade used to prolong blade life

- Slowly side grind and/or cut across the whole cavity

- Cut about halfway through the top ceramic

- You shouldn't need to go all the way to the frit

- Try to make one continuous cut

- Multiple cuts increase change to fragment and create larger debris

- Wash nail polish away with acetone

- See UV masking page for more info

Thermal fracture (old)

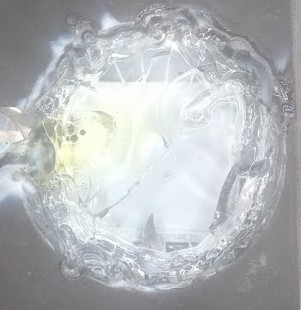

Above: example result

Procedure

- Place package on a temperature resistant surface

- Heat package with a propane torch until hot, maybe 5 or 10 seconds

- Gently splash or sprinkle water on the package. This should create micro-fractures and make it easy to shear

- Shear the package open by applying light force. Unlike a non-fractured package this should be possible using simple pairs of pliers or by hand

Tips:

- Chip does not have to be heated until red or white hot. Heating this high increases risk to damage the die from glass reflowing as well as general thermal stress

- Do not throw the chip into liquid or move it all while it is hot. This can cause the glass to shift and get onto the die

- PDIPs should be supported (ie with a block of metal) as the leadframe will become very weak

- If it does not shear open the first time try again. Consider increasing heat, pressure, or simply do more runs

Advantages:

- Can be very clean and low risk

- Tends to be pretty clean and not throw a lot of debris onto the die

Disadvantages:

- Thermal shock can potentially also break die

- High temperatures can warp die

- The die is exposed but still in the package

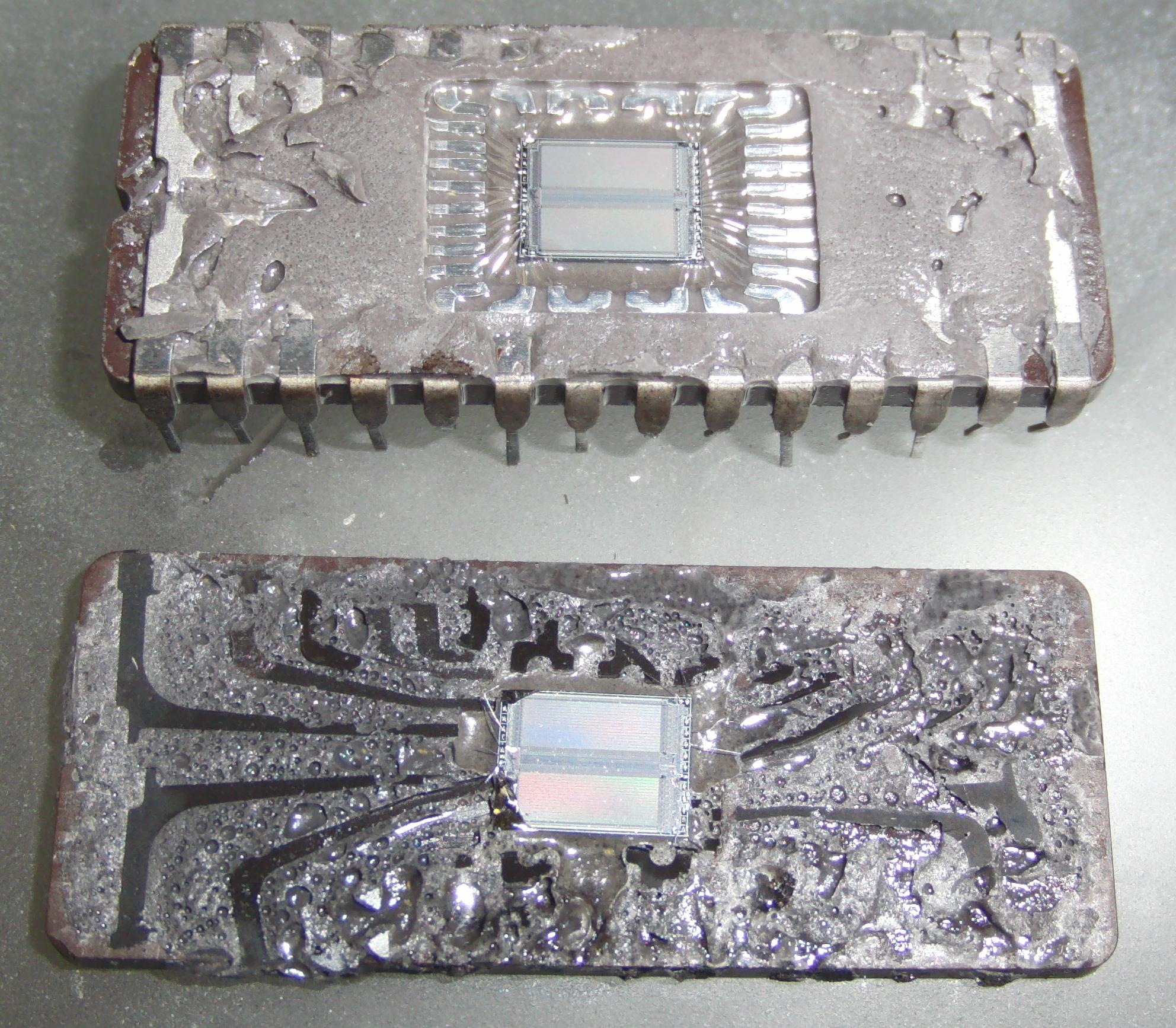

Dunking comparison

Explored a variant where I throw the chip into water

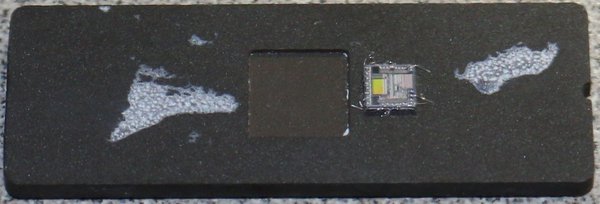

Above: both chips

Above: dunked chip close-up

Above: dripped on chip close-up

The motion of throwing the chip into the water caused the glass to flow and stick to the die. When the top was sheared off some of the die snapped off as a result. Additionally, it isn't as regular from moving around and so didn't break nearly as cleanly.

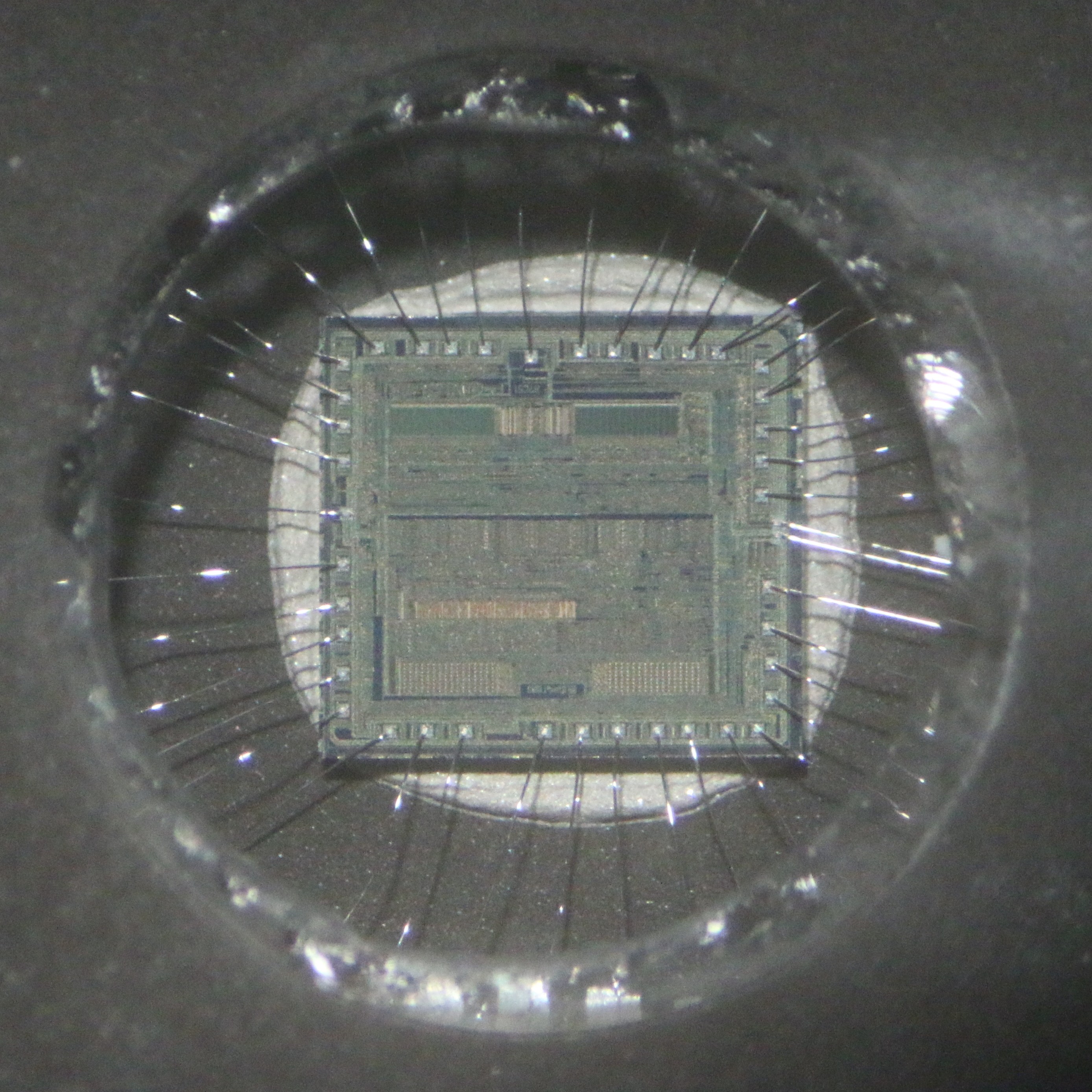

Mill window

Above: operating in progress. Not shown: vacuum removing debris. However, the trail can be seen towards the nozzle

Above: opened chip

I (JM) tried to mill the window out but ran into various issues:

- Even with vacuum, quartz debris tended to fall and land on bond wires, sometimes damaging them

- Especially the window falling at completion

- Occasionally chips would fly at high enough speed to damage die

While this does work, I've had much higher success rate with “top heat” procedure. The main advantage of this procedure is that, if successful, leads to a very intact package. However, given that many attacks involve masking the die, the other techniques also provide better die access

Mill package

Above: test slot. The 1/8” or so endmill broke after 3 CNC passes despite water cooling, slow speed, and shallow depth

Above: only diamond shaped tooth carbide endmills seem to be able to remove ceramic reasonably. From reading online, only carbide or diamond tools should even be considered for ceramics. Diamond studded endmills also exist, but are a bit expensive so I haven't tried them

Laser

40W CO2 laser can melt package, but it didn't evaporate. Also rest of package get severe thermal shock and cracked here and there

Window was easily melted, but had a tendency to slice through the bond wires below

Shearing

The glass tends to be much weaker than the ceramic. Therefore, its possible to shear a chip open by moving the top and bottom half in different directions.

Procedure

- Place bottom half of package into vice. It may be desirable to put a metal space in between the pins to keep pressure more even

- Firmly hold the top of the chip and twist. Keep the movement orthogonal to the glass plane

Ideally this would probably be done using a custom fixture to hold the top and apply even and straight force

Tips

- Plumbing wrenches work well to hold the chip as their width can be adjusted for even pressure while still holding it tightly

- Be careful with long CERDIPs that you don't apply too much torque on an end and snap the chip in half instead of shear it

Advantages

- Very readily available materials

- Does not use any consumables

Disadvantages

- Throws debris onto die

- Can be difficult to effectively grip top half

- Can be difficult to tell how much force is required

- Unpredictable how it will shear

Grinding

Above: failed grind attempt. As the windowed thinned, it tended to shatter

I see no reason why you couldn't grind one open (eg with a Dremel) but it would probably take a long time and would require extensive cleanup after.

JM: tried and shrapnel tended to damage die

Dissolve

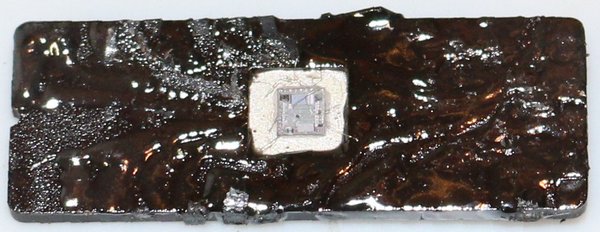

Above: 70% HNO3 dissolving glass frit and (silver epoxy?) die attach

70% HNO3 is known to dissolve the frit. However, it would probably dissolve other things (ie the pins) as well

It should be possible to use HF to dissolve the ceramic. Maybe NaOH could work as well?

Die removal

Typically attached either using silver epoxy or glass. While silver epoxy is relatively easy to remove (see below), glass remains problematic. The fundamental issue is that the melted glass causes very high turface tension, requiring great force to pull the die up. Best advice is that if you don't need to remove the die, don't attempt it.

If someone knows of a good way to remove glass affixed dies I'd be interested. All of these assume the package has already been opened.

IDEA: could I throw some powder in to dilute / weaken the glass? I can still slide the die around, just not get it up

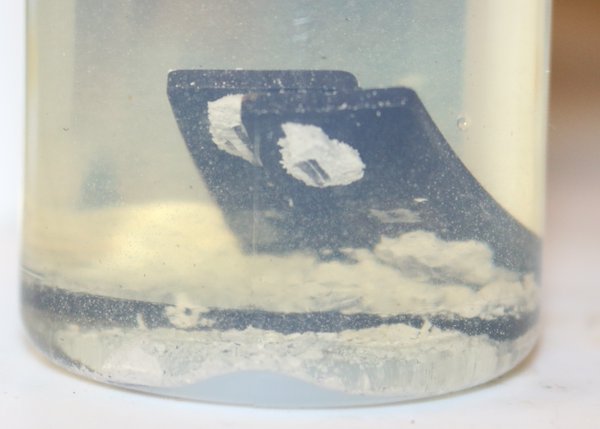

Dissolve epoxy

If the die is silver epoxied in, it can safely removed by soaking in nitric acid (WFNA or 70% better?). This will take some time (on order of days) since the epoxy will very slowly be eaten from side.

Hot pull

Procedure

- Heat lower package

- Gently pickup the die up with metal tweezers or lift up with a sharp knife (which can get between die and substrate easier)

Surface tension makes simply plucking the die up difficult and so a knife tends to work better. Unfortunately, metal tweezers / knives chip dies and plastic tweezers melt. PTFE does a little better but puts off toxic gas (HF) when heated so its not a good idea.

Crack-n-push

Procedure:

- Score one side of the ceramic package well

- Heat package strongly

- Submerge scored side of package in water. This should cause it to crack roughly along score marks

- Re-heat package

- Slide die out of open side of well with die

2016-12: tried using talc to weaken glass and make it come off. Didn't work, but probably worth exploring related techniques. Maybe just a light dusting?